Coal seam mining level setting - Black King Kong report

Preface

In the field of mining engineering, stages, mining levels, and the vertical height of mining levels are extremely important concepts. They profoundly affect the efficiency, cost, and safety of mine mining. A stage refers to a part of the mining area divided along a certain elevation, like dividing the mining area, this "big cake", into long strips according to a specific height. It is the basic unit of division of the mining area in the vertical direction. The mining level, on the other hand, is the horizontal position of the main haulage roadway and the bottom car station and the mining range it serves. It is like a "hub layer" in the mine, coordinating the mining operations in the surrounding area of that horizontal position. The vertical height of the mining level, that is, the vertical distance between the upper and lower boundaries of the mining level, is directly related to the amount of engineering, cost, and the difficulty of subsequent operation and management. It is one of the key indicators to measure the quality of a mining scheme. These basic concepts constitute the cornerstone of mine development design. Only by accurately grasping them can we proceed in an orderly manner in subsequent mining work and achieve efficient mining and utilization of resources.

(Image from MOOC China University of Mining and Technology Mining Engineering Tu Shihao, Fang Zhijun, Zheng Xigui, Wang Xufeng, Peng Hongge, Yuan Yong)

Mining level settings under different coal seam conditions

Near-horizontal coal seam

Due to the small vertical height of near-horizontal coal seams, there are various feasible methods in mining planning. A common practice is to not divide the stages, but directly divide the mining area into panels or zones. This method omits the stage division steps, simplifies the mining layout, and allows mining work to proceed more directly, reducing the complex roadway layout and mining connection problems caused by stage division. For example, in some areas with relatively stable and consistent thickness of near-horizontal coal seams, using this direct zoning method can quickly establish a mining system and improve mining efficiency.

When there are not many coal seams and the interlayer spacing is not large, single-level development is an economical and efficient choice. In this case, one mining level can cover the entire mining range, and the horizontal position of the main haulage roadway and the bottom car station can coordinate the mining operations in all related areas, greatly reducing the development cost and reducing the construction of connecting roadways and equipment configuration between multiple levels. Taking a certain mining area as an example, this area has only two or three coal seams, and the interlayer spacing is within a reasonable range. After adopting single-level development, not only the construction period is shortened, but also the later operation and management costs are reduced.

However, if there are many coal seams to be mined, in order to achieve a more reasonable mining layout and resource utilization, it is necessary to set mining levels according to the coal seams, forming a multi-level development pattern. Different coal seams are suitable for mining at different levels due to differences in their occurrence conditions, coal quality, and other factors. At this time, the vertical height of the mining level is the vertical distance between two levels. This vertical height has no direct relationship with the dip length of the coal seam, mainly depending on the relative position between the coal seams and the requirements of the mining process. Through multi-level development, it is possible to formulate exclusive mining schemes for each coal seam, improve the recovery rate of coal resources, and ensure the safety and efficiency of mining.

Gently inclined and moderately inclined coal seams

(Image from MOOC China University of Mining and Technology Mining Engineering Tu Shihao, Fang Zhijun, Zheng Xigui, Wang Xufeng, Peng Hongge, Yuan Yong)

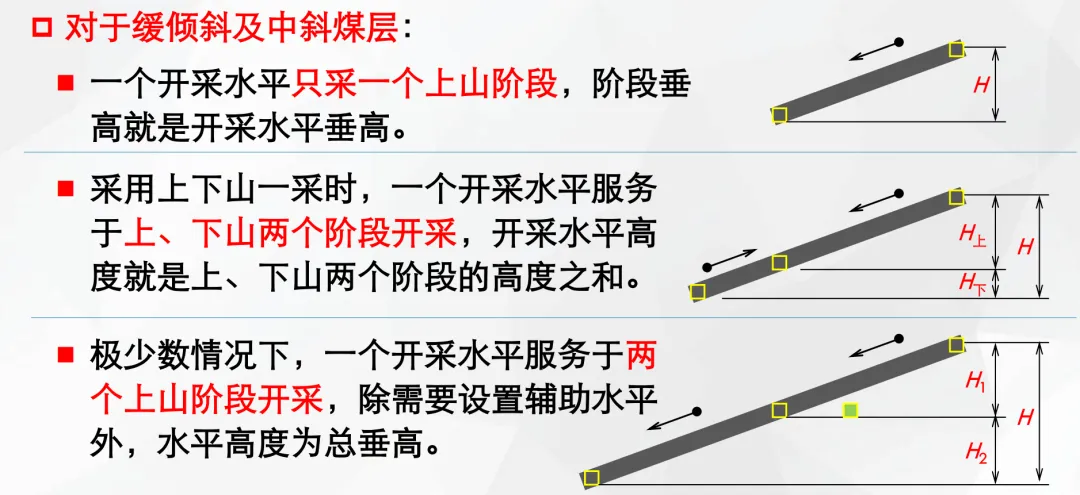

For gently inclined and moderately inclined coal seams, the setting of mining levels is more diverse. Under normal circumstances, when a mining level only mines one uphill stage, the stage vertical height is the vertical height of the mining level. In this mode, mining operations are relatively concentrated within one stage, which is convenient for management and equipment allocation, and the layout of ventilation and transportation systems is relatively simple. For example, in the mining practice of a certain coal mine, the coal seam dip angle in this area is in the gently inclined range. Using one mining level corresponding to one uphill stage makes the advancement of the coal mining face smoother, and production efficiency is effectively guaranteed.

When both uphill and downhill mining are adopted, one mining level serves the mining of both uphill and downhill stages. In this case, the mining level height is the sum of the heights of the uphill and downhill stages. This method increases the mining range and makes full use of the coal resources in the mining area, but it also puts higher demands on mining technology and management. In the downhill mining part, due to the difficulties of upward transportation, drainage, and downward ventilation and excavation, more powerful hoisting equipment, drainage facilities, and reasonable ventilation system design are needed. However, through scientific and reasonable planning and the application of advanced technologies, this method of simultaneous uphill and downhill mining can significantly improve the mine's output and resource utilization rate.

In rare cases, one mining level may also serve the mining of two uphill stages. In this case, in addition to setting auxiliary levels, the level height is the total vertical height. This complex mining layout is usually determined by special geological conditions or resource distribution conditions. Setting auxiliary levels can help solve the problems of transportation, ventilation, and mining connection between different stages, ensuring the smooth progress of the entire mining process. However, at the same time, this method will also increase the amount of roadway excavation, equipment investment, and management complexity, and needs to be carefully adopted after comprehensively considering various factors.

Key factors affecting mining level settings

Coal seam occurrence conditions

Coal seam occurrence conditions are the basic factors affecting the setting of mining levels, among which coal seam thickness, dip angle, and stability play a key role. Coal seam thickness is directly related to coal reserves and mining economic benefits. Thicker coal seams usually provide richer coal resources, so that when setting mining levels, larger mining ranges and higher production capacity can be considered. For example, in some thick coal seam areas, when setting mining levels, larger mining equipment and more efficient mining processes can be used to fully tap the potential of the coal seams. For thin coal seams, due to the relatively small coal reserves and greater mining difficulty, when setting mining levels, more attention should be paid to the refinement and efficiency of mining to reduce mining costs.

The coal seam dip angle also has an important impact on the setting of mining levels. Different dip angles of coal seams require different mining methods and equipment, which in turn affect the division of mining levels. For near-horizontal coal seams, due to their small dip angle, the transportation and ventilation systems in the mining process are relatively simple, and a more flexible mining layout can be adopted, such as the direct division into panels or zones mentioned earlier. As the coal seam dip angle increases, the mining difficulty gradually increases. When setting mining levels, it is necessary to more carefully consider transportation methods, roadway layout, and equipment selection. For example, for steeply inclined coal seams, when setting mining levels, more auxiliary roadways and equipment may need to be set up to solve the problems of coal transportation and personnel passage.

The stability of the coal seam should not be ignored. In the mining process of stable coal seams, the mining conditions are relatively consistent, which is conducive to the use of standardized mining processes and equipment, thereby simplifying the setting of mining levels. However, unstable coal seams, such as those with faults and folds, will cause changes in coal seam thickness and dip angle, increasing the uncertainty and difficulty of mining. In this case, the setting of mining levels needs to be more flexible, and multiple mining levels or auxiliary levels may need to be set according to the changes in the coal seam to ensure the safe mining of coal.

Geological conditions

Geological conditions are important factors affecting the division of mining levels. Geological factors such as faults, folds, and gas content all have a significant impact. The presence of faults will destroy the continuity of the coal seam, making mining work more complex. When the fault throw is large, it may cause a significant change in the position of the coal seam on both sides of the fault, thus affecting the layout of the mining level. For example, when encountering a fault, it may be necessary to replan the direction of the roadway, or even set up auxiliary levels to connect the mining areas on both sides of the fault. In addition, the rock at the fault is broken, and it is easy to cause roof collapse and other safety accidents. Therefore, when setting the mining level, the location and nature of the fault should be fully considered, and corresponding support and safety measures should be taken.

Folds will change the morphology of the coal seam, forming anticlines and synclines. In the anticline, the coal seam is relatively thin, and the roof pressure is relatively large; while in the syncline, the coal seam is relatively thick, but there may be problems such as water accumulation. Therefore, when setting the mining level, the morphology of the fold and the change of the coal seam should be considered to reasonably select the mining area and arrange the roadway to ensure the safety and efficiency of mining. For example, when mining in a syncline area, it is necessary to strengthen the construction of drainage facilities to prevent water accumulation from affecting mining work.

Gas content is also a key factor affecting the setting of mining levels. In coal seams with high gas content, there are safety risks such as gas explosions and gas outbursts during mining. Therefore, stricter ventilation and gas control measures should be taken. When setting mining levels, the distribution of gas should be considered, and ventilation areas should be reasonably divided to ensure that gas can be discharged in time. For example, for areas with high gas content, a special gas extraction system and ventilation roadway can be set up to reduce the gas concentration and ensure mining safety. In addition, advanced gas monitoring equipment and early warning systems should be equipped to monitor the changes in gas concentration in real time and take measures to deal with emergencies in a timely manner.

Mining Technology and Equipment Level

The level of mining technology and equipment plays a key role in the setting of mining levels. With the continuous progress of science and technology, advanced mining technologies and equipment continue to emerge, providing strong support for the optimization of mining level settings. The application of automated mining technology has greatly improved mining efficiency and safety. Through the automated control system, equipment such as coal cutters and excavators can be remotely operated and automatically controlled, reducing manual intervention, reducing labor intensity and safety risks. In setting mining levels, automated mining technology allows the mining range to be determined more flexibly, adapting to more complex geological conditions. For example, in some large coal mines, after adopting automated mining technology, a mining level can serve a larger area, reducing the number of mining levels and reducing construction and operating costs.

Efficient transportation equipment and ventilation systems are also important factors affecting the setting of mining levels. Advanced belt conveyor systems can achieve fast and continuous transportation of coal, improving transportation efficiency and enhancing the coal transportation capacity of mining levels. A powerful ventilation system can ensure good air quality underground and provide a safe working environment for mining personnel. When setting mining levels, efficient transportation and ventilation equipment can support larger-scale mining, expanding the service range of mining levels. For example, in some deep mines, the use of high-power ventilation fans and efficient ventilation networks can effectively solve the ventilation problems of deep mining and provide a guarantee for the reasonable setting of mining levels.

In addition, advanced detection technology and information management systems also provide important basis for the setting of mining levels. Through geological radar, transient electromagnetic and other detection technologies, the occurrence state and geological structure of the coal seam can be more accurately grasped, providing a scientific basis for the division of mining levels. The information management system can monitor various data in the mining process in real time, realizing dynamic management and optimization adjustment of mining levels. For example, using the information management system, the mining plan of the mining level can be adjusted in time according to the mining progress and changes in coal reserves, improving resource utilization.

Resources/Reserves and Production Capacity

The size of resource reserves and the level of production capacity are closely related to the setting of mining levels. Abundant resource reserves are the basis for setting reasonable mining levels, determining the service life and mining scale of mining levels. When resource reserves are large, when setting mining levels, larger mining level vertical height and longer service life can be considered to reduce the number of mining level constructions and reduce costs. For example, in some large coalfields, due to abundant coal reserves, a larger mining level vertical height is adopted, and one mining level can serve for decades or even hundreds of years, achieving long-term stable mining of coal resources.

Production capacity directly affects the setting and operation of mining levels. Higher production capacity requires mining levels to have efficient mining systems and transportation capacity. When setting mining levels, the number and scale of coal mining faces and the configuration of the transportation system should be reasonably planned according to the production capacity target of the mine. For example, for mines with large production capacity, multiple coal mining faces may need to be set up, and large-capacity transportation equipment should be equipped to ensure that coal can be mined and transported to the surface in time. At the same time, the level of production capacity will also affect the succession planning of mining levels. In order to ensure the continuous and stable production of the mine, it is necessary to plan and construct new mining levels in time before the production capacity of the current mining level decreases.

There is also a mutually restrictive relationship between resource reserves and production capacity. If resource reserves are limited and production capacity is too high, it may lead to premature depletion of resources and affect the sustainable development of the mine; conversely, if production capacity is too low and resource reserves are abundant, it will lead to waste of resources and increased mining costs. Therefore, when setting mining levels, it is necessary to comprehensively consider resource reserves and production capacity, achieve optimal matching of the two, and achieve the best economic benefits and resource utilization efficiency.

Summary

The setting of coal seam mining levels is a complex and systematic project that needs to comprehensively consider various factors, including coal seam occurrence conditions, geological conditions, mining technology and equipment level, and resources/reserves and production capacity. For near-horizontal coal seams with small vertical height, they can be directly divided into panels or zones. If there are not many coal seams and the interlayer spacing is small, a single level should be used; if there are many coal groups, multiple levels should be developed according to the coal groups. For gently inclined and moderately inclined coal seams, one mining level can mine one uphill stage, uphill and downhill mining simultaneously, or in a very few cases, two uphill stages, but each method has its specific applicable conditions and technical requirements. The thickness, dip angle, and stability of the coal seam occurrence conditions, the faults, folds, and gas content in the geological conditions, the automated technology, transportation and ventilation equipment, and detection and management systems in the mining technology and equipment level, and the interrelationship between resources/reserves and production capacity all affect the decision-making of mining level setting to varying degrees.

(This article refers to the courseware of Mining Engineering from China University of Mining and Technology on MOOC, by Tu Shihao, Fang Zhijun, Zheng Xigui, Wang Xufeng, Peng Hongge, and Yuan Yong.)