Understanding Deep Hole Mining in One Article - Black King Kong Report

Preface

In modern mining, deep-hole blasting is a crucial mining process that plays a vital role. Deep-hole blasting involves drilling boreholes with a diameter greater than 90mm and a depth greater than 15m using specialized drilling rigs, followed by blasting to break down the ore. Since the 1960s, this technology, with its highly efficient ore-dropping capability, has almost completely replaced chamber blasting, leading to a significant transformation in mining methods. Its emergence has brought numerous significant advantages to the mining industry, greatly improving ore-dropping efficiency, enabling faster and more efficient mining operations, and laying a solid foundation for subsequent mining processes. At the same time, deep-hole blasting technology simplifies the structure of mining methods, reduces unnecessary preparatory roadway engineering, lowers mining costs and labor intensity, significantly improves working conditions and safety, and creates a safer and more comfortable working environment for miners.

Deep-hole blasting layout methods

In actual mining operations, deep-hole blasting layout methods are diverse, each with its unique characteristics and applicable scenarios. Based on different orebody conditions and mining requirements, these layout methods can leverage their respective advantages to ensure efficient mining operations.

Vertical, inclined, and horizontal layouts

Vertical, inclined, and horizontal layouts each have their own advantages in deep-hole blasting. During vertical layered blasting, rock drills or drilling rigs are used in horizontal drilling tunnels, making equipment movement and operation convenient. Pressure blasting technology can also be used, making it a widely used method. For example, in mines with relatively stable rock and regular orebody shapes, vertical layered blasting can fully leverage its advantages to achieve efficient mining. Inclined layered blasting is suitable for situations with larger orebody dip angles, better adapting to the orebody's occurrence conditions. During horizontal layered blasting, drilling is carried out in drilling shafts or chambers, making equipment movement inconvenient and blasting quality difficult to guarantee; however, it can also play an important role under certain specific orebody conditions. In practical applications, vertical or inclined layering often uses parallel layouts. This layout method allows for a more even distribution of explosive energy, resulting in relatively better ore fragmentation. Horizontal layering often uses a fan-shaped layout, which allows for more boreholes to be placed in a limited space, improving ore-dropping efficiency.

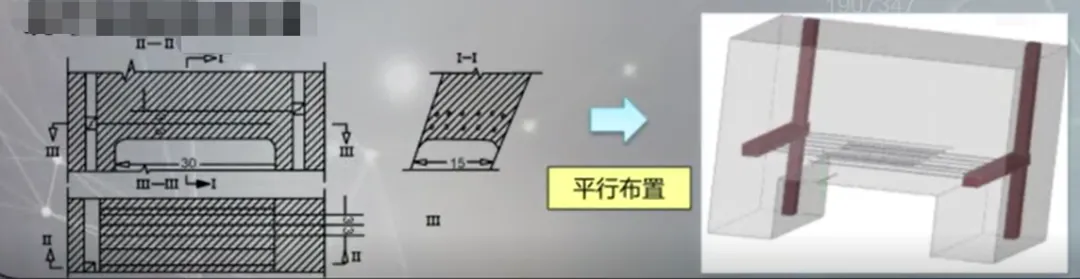

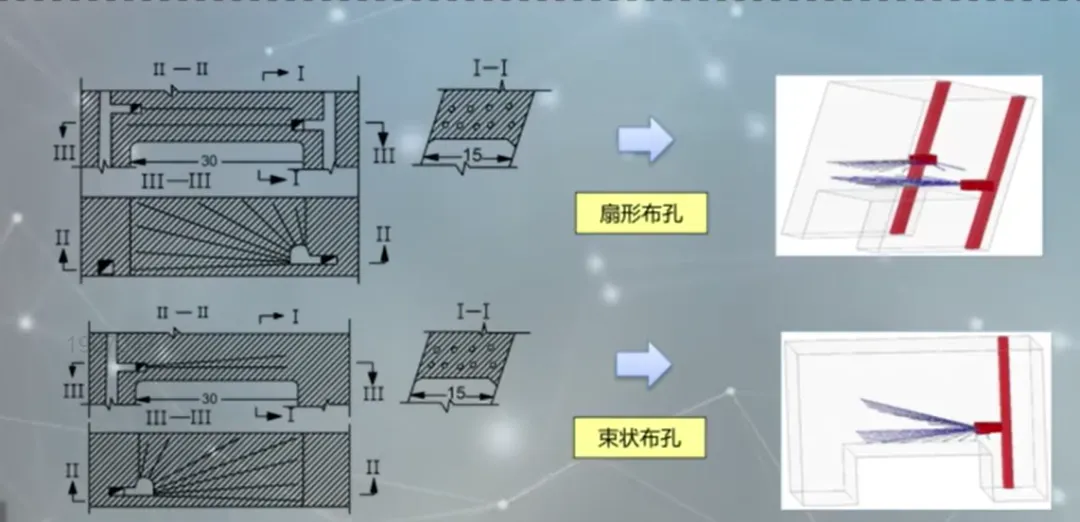

Fan-shaped, parallel, and bundled hole layouts

These three methods—fan-shaped, parallel, and bundled hole layouts—also have significant differences. Parallel deep holes fully utilize the length of the deep holes, the explosive energy distribution is uniform, and the ore fragmentation quality is good; however, the amount of roadway excavation and drilling is large, requiring frequent movement of drilling equipment, resulting in more auxiliary operation time and lower efficiency. In mines with higher requirements for ore fragmentation quality and relatively lower requirements for mining efficiency, the parallel hole layout may be adopted. Fan-shaped deep holes have a small amount of preparatory engineering, flexible borehole layout, and each drilling location can drill several deep holes (one face), reducing the number of times the drilling equipment needs to be moved. Although the total length of fan-shaped boreholes is 50%-60% longer than parallel boreholes, it is widely used in production. Bundled layouts involve drilling several rows of fan-shaped deep holes from the drilling chamber. This layout is generally used for blasting top and intermediate pillars, but rarely used in mining stopes. This is because when blasting top and intermediate pillars, bundled layouts can concentrate explosive energy, effectively achieving the collapse of the top and intermediate pillars.

Borehole strategy based on the contact surface between the orebody and the surrounding rock

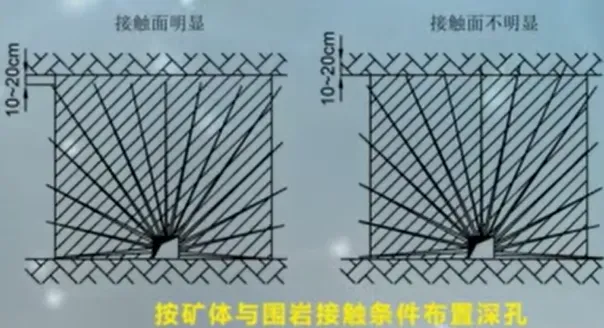

In deep-hole blasting operations, the condition of the contact surface between the orebody and the surrounding rock is a key factor affecting the choice of hole layout method. Different contact surface conditions require different hole layout strategies to ensure optimal blasting results. This is not only related to ore recovery rate but also closely related to mining costs, production safety, and many other aspects.

Hole layout when the contact surface is obvious

When the orebody and surrounding rock are in contact and easily separable, the drilling chamber is usually located within the contact surface. When laying boreholes, the distance between the bottom of the hole and the hanging wall contact surface should be maintained at 10-20cm. This is because if the bottom of the hole is too close to the hanging wall contact surface, too much surrounding rock may be blasted during blasting, leading to ore depletion, increasing the difficulty and cost of subsequent ore dressing. In the mining of a certain iron mine, due to the obvious and easily separable contact between the orebody and the surrounding rock, this hole layout method was adopted, effectively controlling the ore depletion rate and improving the quality of the ore. This hole layout method can also fully utilize the natural separation characteristics of the orebody and surrounding rock, reducing unnecessary explosive energy consumption and improving blasting efficiency.

Hole layout when the contact surface is not obvious

When the contact surface between the orebody and the surrounding rock is not obvious and shows a gradual relationship, the drilling chamber is located 0.5-1m outside the footwall vein. This layout can better adapt to the transition zone between the orebody and the surrounding rock, reducing ore loss. The side holes are laid on the footwall contact surface, and the bottom of the hole is over-drilled 0.2-0.4m into the hanging wall surrounding rock to prevent ore from remaining at the contact surface. In the mining process of a certain copper mine, facing the situation where the contact surface between the orebody and the surrounding rock is not obvious, the above-mentioned hole layout method was adopted, effectively reducing ore loss and improving resource utilization. The over-drilling setting ensures that during blasting, the ore near the hanging wall surrounding rock can be fully blasted, avoiding resource waste due to ore residue.

Common equipment

Deep-hole blasting relies on advanced equipment support. Different types of equipment play a key role in the blasting process, and their performance and characteristics directly affect the efficiency and quality of blasting.

Down-the-hole drill rigs

Sub-drilling rigs are widely used in deep-hole mining. Taking the CS150H sub-drilling rig as an example, it is specifically designed for underground mine conditions. Through system integration technology, the overall size is designed to be low-profile, with a small turning radius, flexible movement, and high safety. The overall width is 1200mm, and the traveling height is less than 1850mm. It can be directly transported to the designated middle section via a No. 3 cage without disassembling the entire machine, making field transfers very convenient. At the Piaotang Tungsten Mine, the CS150H sub-drilling rig's field blasting holes are designed as fan-shaped holes, with a construction diameter of 90mm and a maximum depth of 65m. The construction efficiency is approximately 40m/shift, with a cumulative construction of nearly 50,000 meters. The hole deviation rate of this type of drill can be controlled below 0.5%, and the drilling angle can be switched within the range of -5° to 90° vertically and 360° horizontally, making it particularly suitable for drilling circular holes in underground mines. Its traveling system uses hydraulic motor drive, tire travel, soft-characteristic start-stop control, and hydraulic wet braking. It has high traction and climbing ability, and can also achieve 360°原地转向.

Mining Trolley

Mining trolleys are also important equipment for deep-hole mining. Xintong Machinery's XTDL-1, XTDL-3, and XTDL-4 series of underground medium and deep-hole mining trolleys adopt a narrow body and short drill arm design concept, adapting to operations with varying cross-sectional sizes. It uses a Cummins diesel engine for travel, four-wheel drive, tire travel, and a climbing ability of 15°. The vehicle body frame is connected by a middle hinge structure, with a turning radius of only 2.5/4.7 meters, a ground clearance of 265mm, and strong passability. It is equipped with an air compressor system and a water pump system, and also has an automatic rod connection library. When the connection hole depth ≤20m and the diameter ≤76mm, it is equipped with an Atlas 18U rock drill, using a 915mm rod (weight 8kg), with a rod capacity of 10+1, meeting the requirements for 10m automatic rod connection. If a deeper hole needs to be drilled, after the rods in the rod sleeve are used up, auxiliary workers can add rods to the rod sleeve to continue drilling.

Analysis of Deep-Hole Extrusion Mining Technology

Deep-hole extrusion mining, as an important method in deep-hole mining technology, plays a unique role in modern mining operations. Through ingenious design and technical means, it achieves efficient mining under specific conditions, bringing new ideas and methods to mine mining.

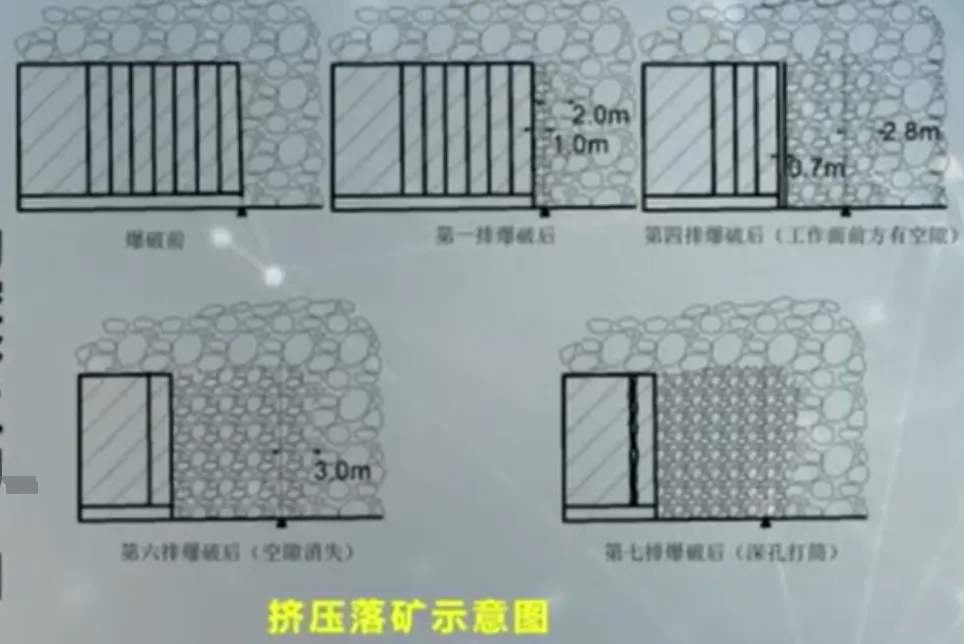

Principle of Deep-Hole Extrusion Mining

The principle of deep-hole extrusion mining is based on mining operations under conditions of smaller compensation space. When blasting, the collapsed ore cannot be fully loosened as in free-space blasting. At this time, with the help of the powerful force generated by the blasting, the ore will collide and extrude towards the adjacent loose medium. In this process, the ore obtains the required compensation space through interaction with the loose medium, and also achieves auxiliary crushing. This unique mining method allows for more efficient use of explosive energy, thereby improving the ore crushing quality and mining efficiency. In the mining of a certain lead-zinc mine, using deep-hole extrusion mining technology, by precisely controlling the blasting parameters and compensation space, the ore crushing effect was significantly improved, providing strong support for subsequent mining and beneficiation work.

Analysis of Key Elements

1. Comparison of Compensation Space Free-space blasting and extrusion blasting have obvious differences in compensation space. Free-space blasting usually requires a compensation space of 20% - 30% to ensure that the collapsed ore can be fully loosened. The compensation space for extrusion blasting is relatively small, generally only 12% - 20%. This is because extrusion blasting obtains compensation space through the extrusion of ore towards adjacent loose media, rather than pre-leaving a large amount of space. This difference allows extrusion blasting to reduce the amount of mining preparation work and improve mining efficiency in some cases.

2. Extrusion Mining with Small Compensation Space Extrusion mining with small compensation space is an important form of deep-hole extrusion mining. In this method, a small amount of cutting work, such as cutting slots and cutting wells, is excavated in the designed mining body as compensation space. The volume of these compensation spaces is generally controlled at 10% - 20%. This method not only reduces the amount of cutting work and lowers mining costs but also improves the ore crushing effect. In the mining of a certain copper mine, using extrusion mining technology with small compensation space, by reasonably designing cutting work and blasting parameters, the amount of cutting work was effectively reduced, while reducing the output of large pieces and improving the quality of the ore.

3. Extrusion Mining towards Adjacent Collapsed Ore Extrusion mining towards adjacent collapsed ore involves several key elements. Loose ore discharge is a necessary condition for achieving this extrusion blasting. By controlling the loose ore discharge amount at 15% - 20%, the compacted collapsed ore can be restored to a normal loose state, providing good extrusion space conditions for subsequent blasting. The design of the first row of blasting holes is crucial; it needs to have greater energy to compensate for the energy loss caused by the absorption of blasting stress waves entering the loose medium. Usually, a row of blasting holes is added 0.4 - 0.6 meters behind the first row of blasting holes to enhance the blasting effect. The choice of the thickness of the ore layer for single blasting also affects the extrusion blasting effect. Increasing the thickness can reduce the number of blasts and increase the amount of ore blasted each time, but if the thickness is too large, the compensation space obtained from the loose medium will gradually decrease. In practical applications, the thickness of the ore layer for single blasting needs to be reasonably determined according to the specific situation.

Application Effect Evaluation

The application effect of deep-hole extrusion blasting is closely related to the correct application of the technology. When applied correctly, it can significantly reduce the large-piece rate, making the ore size more uniform, facilitating subsequent transportation and beneficiation operations. It improves ore extraction efficiency, reduces the amount of cutting work, lowers mining costs, increases the mining intensity, and brings good economic benefits to the mine. In the mining of a certain iron mine, after adopting deep-hole extrusion blasting technology, the large-piece rate was reduced by 30%, and the ore extraction efficiency was increased by 40%, achieving significant results. If applied improperly, it will lead to serious consequences. It may collapse the electric scraper road, causing the ore to fail to be discharged smoothly, resulting in a large loss of national resources. Unreasonable blasting parameters may lead to excessive or uneven ore crushing, affecting the mining effect and economic benefits. Therefore, when applying deep-hole extrusion blasting technology, various factors must be fully considered, scientific design and strict operation must be carried out to ensure the effectiveness and safety of the technology.

Comprehensive Evaluation of Deep-Hole Drilling

Deep hole blasting, as an important mining technique, plays a key role in modern mining. It has unique advantages, but also some limitations, and specific applicable conditions.

Advantages Analysis

1. Significantly Improved Labor Productivity Compared to shallow and medium-deep hole mining, deep hole mining has a larger hole depth and diameter, allowing a single blast to break more ore. In the mining of a large iron mine, after adopting deep hole mining technology, the amount of ore broken per blast hole increased several times compared to shallow hole mining, greatly increasing the amount of ore mined per unit time. This allows mining operations to be more efficient, reducing mining time and labor costs, and significantly improving labor productivity.

2. Effective Reduction in Mining Preparation Engineering Deep hole mining technology simplifies the structure of mining methods and reduces unnecessary mining preparation roadway engineering. In mines with suitable ore body conditions, the use of deep hole mining can reduce the length and number of mining preparation roadways, reducing mining costs and labor intensity. A copper mine reduced mining preparation engineering by 30% through the use of deep hole mining technology, saving a large amount of manpower, material resources, and financial resources, and accelerating the mining progress.

3. Significant Improvement in Working Conditions and Safety During deep hole mining, workers do not need to perform frequent drilling operations at close range, reducing direct contact with blasting operations. This reduces the risk of workers being injured by blasting and dust pollution, improving working conditions. In some underground mines, using deep hole drilling jumbos for operations allows workers to operate equipment in a relatively safe location, improving work safety. Deep hole mining also reduces the exposed area and time of the stope roof, reducing the probability of roof collapse accidents.

Disadvantages Discussion

1. High Percentage of Large Blocks During deep hole mining, due to the large distance between blast holes, the distribution of explosive energy is not uniform, which can lead to uneven ore fragmentation and the production of a large number of large ore blocks. These large ore blocks will increase transportation difficulty and beneficiation costs in subsequent transportation and beneficiation processes. In the mining of a lead-zinc mine, the percentage of large blocks in deep hole mining reached 20%, requiring a large amount of secondary crushing work, which not only increased production costs but also reduced production efficiency.

2. Large Loss at the Ore-Rock Contact Zone At the ore-rock contact zone, due to differences in rock properties and the influence of blasting, ore loss is likely to occur. In the footwall of the ore body, due to the movement and fragmentation of rocks during blasting, some ore may remain in the footwall rocks and cannot be effectively mined. In a gold mine, due to losses at the ore-rock contact zone, the ore recovery rate decreased by 10%, resulting in resource waste.

3. High Ore Dilution In the hanging wall of the ore body, blasting can easily cause excessive surrounding rock to collapse, resulting in a large amount of waste rock mixed into the ore, thus diluting the ore. This will reduce the grade of the ore, increasing the difficulty and cost of beneficiation. In the mining of a molybdenum mine, due to ore dilution, the beneficiation cost increased by 20%, reducing the economic benefits of the mine.

Applicable Conditions Clearly Defined

Deep hole mining is suitable for ore bodies with a thickness greater than 5-8m, regular ore body morphology, and easily separable ore and rock. When the ore body thickness is small, using deep hole mining may lead to ore loss and increased dilution, and the blasting effect is poor. For irregularly shaped ore bodies, the blast hole layout and blasting parameters of deep hole mining are difficult to accurately control, which will affect the mining effect. If the ore and rock are not easily separable, excessive surrounding rock is easily blasted during blasting, increasing the ore dilution rate. In the mining of a certain mine, due to the ore body thickness being less than 5m, after using deep hole mining, the ore dilution rate was as high as 30%, seriously affecting the economic benefits of the mine. Therefore, when choosing a mining method, it is necessary to consider various factors comprehensively based on the specific conditions of the ore body and reasonably select deep hole mining technology.

In the deep veins, deep hole mining is like a silent pioneer, using "arms" with a diameter exceeding 90mm and a depth exceeding 15m, quietly rewriting the history of mining. Since the 1960s, it has gently yet firmly replaced chamber blasting, simplifying the complex structure of mining, reducing the arduousness of roadway excavation, allowing miners to breathe a sigh of relief from heavy labor, and injecting new vitality into mines while improving efficiency. When deep holes are embedded in the ore body vertically, obliquely, or horizontally, and when fan-shaped, parallel, or bundled hole layouts outline precise trajectories in the rock formations, it is not just a presentation of technology, but more like a dialogue with the earth. The angle of each borehole and the setting of each section of the hole spacing all contain gentle considerations for the ore body and surrounding rock—a distance of 10-20cm is for careful avoidance of surrounding rock collapse; a 0.5-1m layout outside the vein is for reducing ore residue.

Previous Page