Support pressure of mining field exposure surface - Black King Kong report

I. Introduction

In the field of mining engineering, the study of stope exposed surfaces and pillars has always been of paramount importance, and its importance cannot be overemphasized. As the direct operation area for ore mining, the stability of the stope's exposed surface is directly related to the safe and efficient progress of mining operations. Once the stope's exposed surface becomes unstable, it may cause serious accidents such as roof collapse and spalling, which will not only pose a huge threat to the lives of on-site workers, but also may lead to equipment damage and production interruption, causing incalculable economic losses to mining enterprises.

As a key structure to support the stope roof and maintain the stability of the stope, the design rationality and bearing capacity of the pillar are also crucial. A reasonably designed pillar can effectively disperse the roof pressure, prevent excessive roof subsidence and collapse, and ensure the stability of the stope throughout the mining process. If the pillar design is unreasonable, the strength is insufficient, or the size is too small, the pillar may yield and be damaged during the mining process, which may lead to a large area of stope instability, and the consequences are unimaginable.

When discussing stope exposed surfaces and pillars, abutment pressure is a core concept that cannot be avoided. Abutment pressure refers to the additional stress generated in the surrounding rock of the stope due to the formation of mining space and the redistribution of original rock stress during mining activities. Its distribution law and magnitude directly affect the stability of the stope exposed surface and the bearing performance of the pillar. For example, under the action of abutment pressure, the surrounding rock of the stope exposed surface may be deformed and fractured, thereby reducing its stability; and if the pressure borne by the pillar exceeds its bearing capacity, it will lead to pillar damage. Therefore, in-depth understanding of the relevant knowledge of abutment pressure is irreplaceable for ensuring the safety and efficiency of mining engineering, which is also the key content of this article.

II. Basic Concepts of Abutment Pressure

(I) Definition and Formation Principle

The generation of abutment pressure is closely related to the formation of mining space in mining activities. When roadway excavation or ore mining is carried out in the rock mass, the original rock stress balance state is broken, and the weight of the overlying rock above the mining space can no longer be uniformly supported by the original rock mass, but is instead borne by the surrounding rock on both sides or specially set pillars. This leads to a significant increase in the pressure borne by the surrounding rock on both sides compared to before excavation. This increased pressure is the abutment pressure, and the range affected by the pressure increase is called the abutment pressure zone.

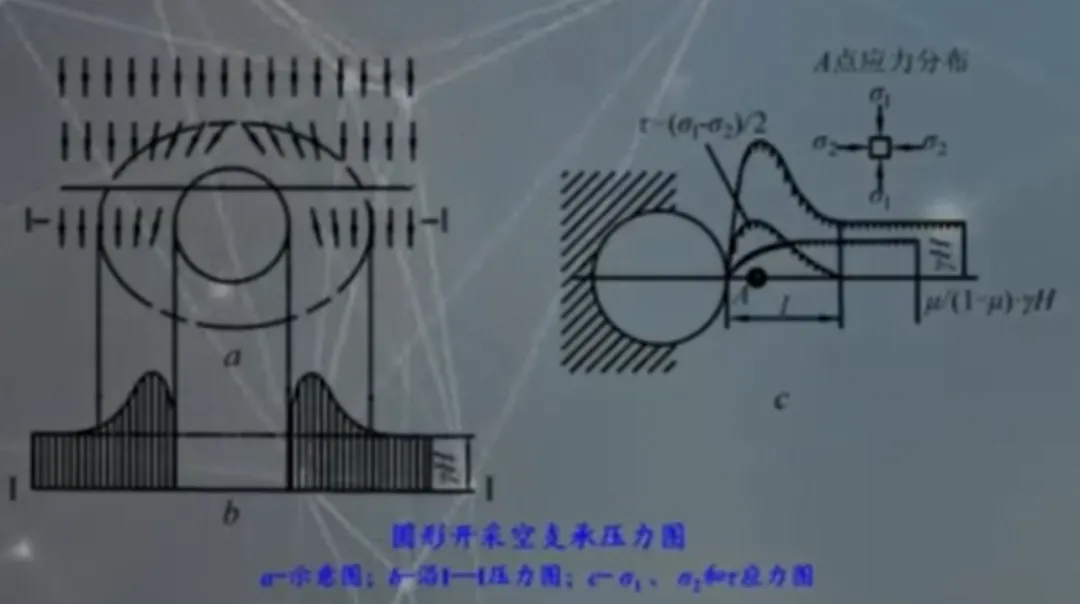

Taking a circular excavation space as an example (combined with the abutment pressure diagram of the circular excavation space), the stress inside the rock mass is in a relatively uniform original rock stress state before excavation. However, once a circular space is excavated, the stress state of the surrounding rock mass will change significantly. The originally uniformly distributed stress will concentrate on the surrounding rock on both sides, making the pressure borne by the surrounding rock on both sides increase significantly, thereby forming abutment pressure. This redistribution of stress is to adapt to the new mining space structure, trying to achieve a new equilibrium state under the new conditions.

(II) Stress Distribution Characteristics

On the I - 1 line of the mining space, the stress distribution shows obvious regularity changes. The vertical stress (tangential stress) σ₁, the horizontal stress (radial stress) σ₂, and the shear stress τ each have their own unique change rules.

The value of the horizontal stress σ₂ on the boundary of the mining space is zero. This is because at the boundary, the rock mass loses the constraint on one side, and there is no squeezing effect from that direction, so the horizontal stress is zero. As the distance from the mining space increases, the constraint of the surrounding rock mass on the rock mass gradually increases, and the horizontal stress also gradually increases. When a certain distance is reached, the horizontal stress will gradually approach and reach the normal value of the original rock stress γH, at which time the stress state of the rock mass gradually returns to a level close to the original rock stress.

The change trend of the vertical stress σ₁ is different from that of the horizontal stress. Near the mining space, due to the concentrated effect of the overlying rock weight and the stress concentration effect, the vertical stress σ₁ will reach its maximum value. This maximum value is often much higher than the original rock stress, posing a greater threat to the stability of the surrounding rock. As the distance from the mining space increases, the vertical stress gradually decreases, the reason being that the stress is gradually dispersed during the transmission process, and the surrounding rock mass jointly bears the pressure of the overlying rock, reducing the pressure per unit area. Eventually, the vertical stress will also decrease to the normal value of the original rock stress γH, indicating that the rock stress here has basically returned to the state before being affected by mining.

The shear stress τ maintains a certain relationship with the vertical stress σ₁. The magnitude and distribution of the shear stress are affected by the vertical stress and the structural characteristics of the rock mass. In areas with large vertical stress, the shear stress is also correspondingly large, because the large vertical pressure will promote the tendency of relative dislocation inside the rock mass, thereby triggering shear stress. Moreover, the direction and magnitude of the shear stress will change with the change of the distance from the mining space to adapt to the distribution and adjustment of stress inside the rock mass.

III. Abutment Pressure Conditions in Different Mining Spaces

(I) Single Roadway and Gently Inclined Mining Space

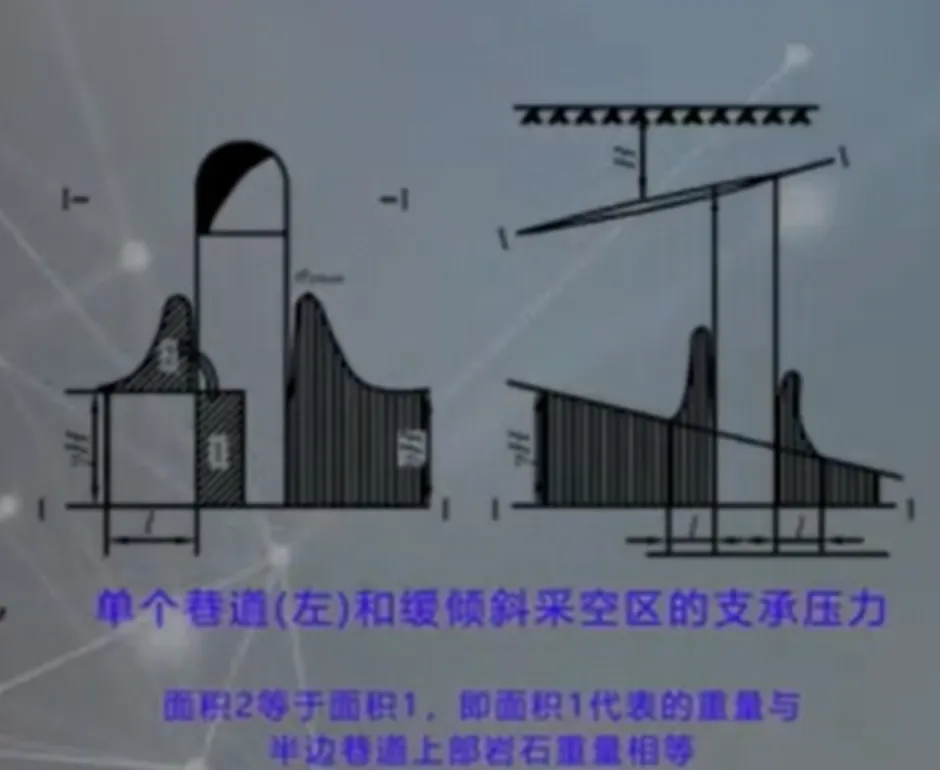

In the case of a single roadway and a gently inclined mining space, the area of the stress increase range in the abutment pressure zone on both sides has a clear calculation method and is closely related to the original rock stress and the span of the mining space.

Specifically, the area of the stress increase range is equal to the product of the original rock stress γH and half of the span of the mining space. This relationship shows that the greater the original rock stress and the greater the span of the mining space, the greater the area of the stress increase range in the abutment pressure zone. The original rock stress γH reflects the weight of the overlying strata, which is the fundamental cause of abutment pressure. When the original rock stress increases, it means that the weight of the overlying strata increases, and the surrounding rock on both sides needs to bear greater pressure, thereby expanding the range of the abutment pressure zone. The increase in the span of the mining space requires more support force for the roof, and the pressure borne by the surrounding rock on both sides also increases accordingly, which in turn leads to an increase in the area of the stress increase range. For example, in a mine with a large mining depth and high original rock stress, if the span of the mining space is 10 meters and the original rock stress is γH = 20MPa, then according to the formula, the area of the stress increase range is 20MPa × (10 meters ÷ 2) = 100 square meters. This clearly shows the influence of the original rock stress and the span of the mining space on the area of the stress increase range in the abutment pressure zone.

(II) Two Roadways or Adjacent Mining Spaces

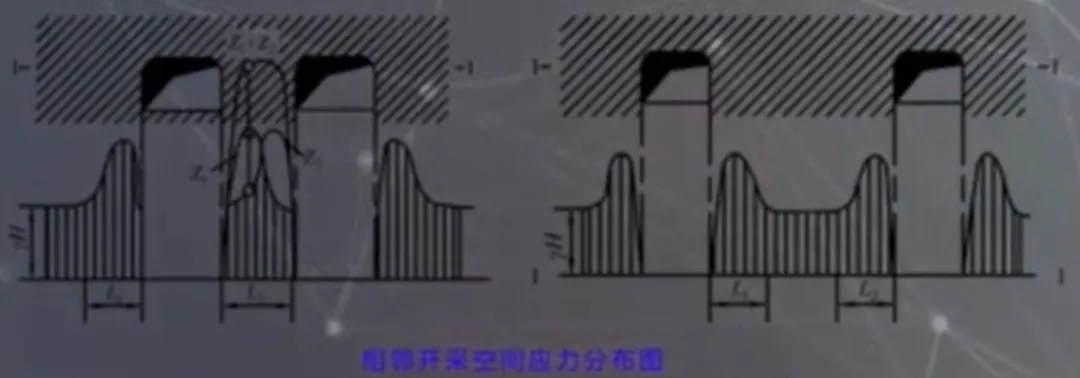

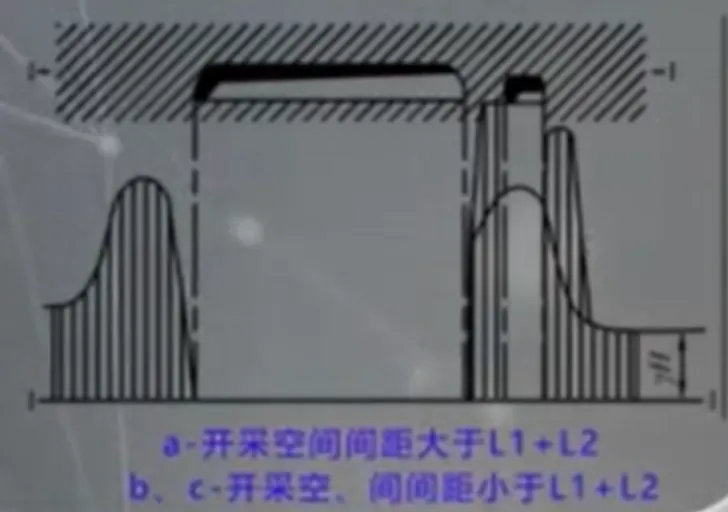

When it comes to two roadways or two adjacent mining spaces, the size of the roadway spacing has a significant impact on the stress distribution.

When the roadway spacing is greater than L1 + L2, its stress distribution law is the same as that of a single mining space. In this case, the interaction between the two mining spaces is small, and the stress distribution around them is mainly affected by their own mining activities. They can be regarded as two independent single mining spaces, and the support pressure zones on both sides of each space develop according to the stress distribution law of single roadways and gently inclined mining spaces. For example, in a large-scale mining area, the distance between two roadways is large, far exceeding L1 + L2. At this time, observing one of the roadways will reveal that the stress distribution around it exhibits characteristics similar to that of a single roadway, forming obvious support pressure zones on both sides of the roadway, and the variation laws of vertical stress, horizontal stress, and shear stress are also consistent with those of a single roadway.

However, when the roadway spacing is less than L1 + L2, the situation changes significantly. The stress in the adjacent part will be greater than the support pressure of a single roadway because the rock mass between the two mining spaces is jointly affected by the mining activities on both sides, resulting in stress superposition. Combining the stress distribution map of adjacent mining spaces (Figure b, c) can more intuitively understand this phenomenon. As can be seen in the figure, when the roadway spacing is small, the area stress between the two mining spaces increases significantly, and stress concentration occurs. This stress superposition may lead to increased deformation and damage of the rock mass, posing a greater threat to the stability of the roadway. For example, in some coal mines with closely spaced coal seam mining, the roadway spacing between the upper and lower coal seams is small. Due to stress superposition, the intermediate coal pillar bears huge pressure, which can easily lead to coal pillar yielding, fracturing, and other phenomena, which in turn can cause roof collapse and other accidents. Therefore, when carrying out mine mining planning, the influence of roadway spacing on stress distribution must be fully considered, and the roadway spacing should be reasonably determined to ensure the safety and stability of the mining process.

IV. Practical Application and Engineering Significance

(I) Impact on Mining Safety

Support pressure has a profound and direct impact on mining safety, mainly reflected in the impact on the stability of the mining face and the bearing capacity of the pillars, and once these impacts exceed the safety range, they may trigger a series of serious safety accidents.

In terms of the mining face, support pressure is one of the key factors leading to its instability. When the surrounding rock of the mining face is subjected to support pressure, the surrounding rock of the mining face will bear additional stress. If this stress exceeds the strength limit of the surrounding rock, the surrounding rock will undergo deformation, fracture, and other phenomena. For example, in some mines with large mining depths and high original rock stress, the surrounding rock of the mining face may experience problems such as roof subsidence and spalling under the long-term action of support pressure. Roof subsidence will reduce the mining space and affect the normal operation of equipment and the activity space of personnel; spalling may cause the rock mass at the edge of the mining face to suddenly collapse, posing a direct threat to nearby operators and equipment. If these problems are not dealt with in a timely and effective manner, as mining continues, the support pressure will continue to change, and eventually may lead to a large-scale roof collapse accident, causing serious casualties and property losses.

As an important structure to maintain the stability of the mining face, the impact of support pressure on the bearing capacity of the pillars cannot be ignored. The pillars are usually arranged and designed according to certain bearing capacity standards. However, in the actual mining process, the existence of support pressure will change the pressure on the pillars. When the support pressure is too large, the pillars may yield, be damaged, etc. For example, in some mines with small spacing between adjacent mining spaces, due to stress superposition, the pressure on the pillars far exceeds their design bearing capacity, resulting in cracks, fractures, and other phenomena in the pillars. Once the pillars are damaged, they cannot effectively support the roof, which may lead to instability of the mining face, which may lead to serious consequences such as roof collapse and surface subsidence. Moreover, the damage of the pillars may also trigger a chain reaction, affecting the stability of other pillars around them, further expanding the scope and harm of the accident.

(II) Application in Mining Design

The law of support pressure distribution plays a pivotal guiding role in mining design. The rational application of these laws can significantly optimize mining design and improve the safety and efficiency of mining operations.

In determining the roadway spacing, the law of support pressure distribution is an important basis. As mentioned above, when the roadway spacing is greater than L1 + L2, the stress distribution law is the same as that of a single mining space, and the mutual influence is small; when the roadway spacing is less than L1 + L2, stress superposition will occur, which is not conducive to the stability of the roadway. Therefore, in mining design, it is necessary to accurately calculate the values of L1 and L2 according to the specific geological conditions and mining requirements, and reasonably determine the roadway spacing. In a mine with relatively complex geological conditions, through detailed measurement and analysis of rock mechanical parameters, combined with numerical simulation technology, it is determined that under the current mining conditions, the roadway spacing should be maintained at a certain value greater than L1 + L2 to ensure that the stress distribution around the roadway is within a safe range and avoid roadway deformation and damage due to stress superposition. This can not only reduce roadway maintenance costs, but also ensure the smooth progress of the mining process.

The determination of the mining face size is also inseparable from the consideration of the law of support pressure distribution. If the mining face size is too large, it will lead to an increase in the exposed area of the roof and a corresponding increase in the support pressure, thereby increasing the risk of roof collapse; if the mining face size is too small, it will affect the mining efficiency. Therefore, when designing the mining face size, it is necessary to comprehensively consider factors such as original rock stress, rock mass strength, and mining technology, combined with the law of support pressure distribution, to determine a reasonable size that can ensure the stability of the mining face and meet the requirements of mining efficiency. For example, in a mine with low roof rock mass strength, in order to reduce the impact of support pressure on roof stability, the span and length of the mining face are appropriately reduced, and the mining sequence is optimized, and methods such as zonal mining and interval mining are adopted to effectively disperse the support pressure and ensure the safety and stability of the mining face.

The selection of pillar size and layout is also a key link in mining design, and the law of support pressure distribution plays a key role in this process. The size and layout of the pillars directly affect their bearing capacity and the maintenance effect on the stability of the mining face. According to the law of support pressure distribution, in areas with large support pressure, the pillar size should be appropriately increased or the number of pillars should be increased to improve the bearing capacity of the pillars and ensure that they can effectively support the roof; in areas with small support pressure, the pillar size can be appropriately reduced to improve the ore recovery rate. In some mines with large mining depths and high support pressure, the pillars near the edge of the mining face and the stress concentration area are enlarged and densely arranged to enhance the bearing capacity of the pillars and effectively prevent pillar damage and mining face instability; while in some areas inside the mining face with relatively small stress, the pillar size is appropriately reduced to increase the ore mining volume while ensuring the stability of the mining face. By reasonably selecting the pillar size and layout, the balance between mining safety and economic benefits is achieved.

V. Summary

The stability of the stope exposure surface and pillars is closely related to the abutment pressure, which is crucial in mining engineering. Abutment pressure is generated due to the disruption of the original rock stress balance by mining activities, and its distribution pattern has a profound impact on the stability of the stope and pillars.

In single roadways and gently inclined mining spaces, the area of stress increase within the abutment pressure zone is closely related to the original rock stress and the span of the mining space. When two roadways or adjacent mining spaces are involved, the size of the roadway spacing directly determines the stress distribution. Too small a spacing can lead to stress superposition, increasing the risk of rock deformation and failure.

In actual mining operations, the impact of abutment pressure on mining safety cannot be ignored. It may lead to instability of the stope exposure surface, causing problems such as roof subsidence and spalling, and even large-scale roof collapse accidents; at the same time, it may also reduce the bearing capacity of the pillars, leading to pillar yielding and failure, and then causing overall stope instability. Therefore, in mining design, the distribution law of abutment pressure must be fully considered, and the roadway spacing, stope size, and pillar size and layout should be reasonably determined to ensure the safe operation of mining operations and improve mining efficiency.