Core Applications and Implementation Strategies of Multi-Process Parallel Operations — Black Diamond Broadcast

Core Applications and Implementation Strategies of Multi-Process Parallel Operations

- Core Processes and Implementation Measures of Parallel Operations

In the rapid tunneling process of flat drifts, from the perspective of fully utilizing effective tunneling cycle time, the multi-process parallel operation mode shows significant advantages. This approach has also been strongly validated in rapid flat drift tunneling practices both domestically and internationally. In the entire flat drift construction project, tunneling and support are the main tasks, and for tunneling work, drilling and rock bolting are the key processes to achieve parallel operations.

Currently, there are two main measures to achieve parallel operations of drilling and rock bolting. First, after blasting, the drilling workstation operates on the rock pile, while rock bolting is carried out at a position farther from the working face. If appropriate rock throwing measures are taken during blasting, drilling of the upper blast holes on the working face can be synchronized with rock bolting. This method is relatively common in rapid flat drift tunneling in domestic mines and has achieved certain results. Generally, rapid tunneling teams place great emphasis on parallel operations of main processes, and in practice, the parallel operation time of main processes often accounts for more than 40% of the total tunneling cycle time, greatly shortening the tunneling cycle and playing an important role in accelerating tunneling speed. Second, after blasting, the rock close to the working face is first cleared 3-5 meters away using a bucket loader or manually, then drilling and rock bolting proceed simultaneously.

In recent years, the scope of parallel operations across various processes has shown a trend of further expansion, gradually forming the "Top Ten Parallel" operations. Besides parallel drilling and rock bolting, it also includes drilling and support (mainly temporary support). During tunneling, when drilling reaches a certain stage, temporary support work can be carried out simultaneously to provide safety assurance for subsequent construction; drilling and track laying, where at an appropriate time, track laying is done alongside drilling to improve construction efficiency; drilling and maintenance of rock bolting machines, where maintenance is performed during drilling intervals to ensure normal equipment operation; drilling and ventilation duct connection to ensure normal air supply to the drilling machine; charging and surveying, where surveying is conducted simultaneously with charging to arrange time reasonably; rock bolting and support (mainly erecting temporary support columns), where temporary support columns are installed during rock bolting; centerline monitoring and working face inspection, etc. Some tunneling teams even have more projects running in parallel.

Advantages and Safety Challenges of Parallel Operations

The advantages of parallel operations are multifaceted. From the perspective of time utilization, it synchronizes multiple processes, reducing idle time of equipment and personnel, making full use of limited construction time, and greatly improving construction efficiency. For example, in a certain mine's flat drift tunneling project, before adopting parallel operations, a tunneling cycle took a long time with processes carried out sequentially, causing resource waste due to equipment and personnel waiting. After adopting parallel operations, processes are closely linked, effectively shortening the tunneling cycle and increasing tunneling speed. From the perspective of space utilization, parallel operations can reasonably arrange the construction positions of different processes within limited working space, fully leveraging the space. In some relatively narrow flat drifts, through careful planning of work areas for each process, drilling, rock bolting, and support can be carried out simultaneously, improving construction efficiency. Especially in most Chinese mines where mechanization and productivity are not high, parallel operations can fully utilize workers' initiative by reasonably arranging processes, accelerating tunneling speed, and enhancing mine production capacity.

However, parallel operations inevitably bring some safety challenges. Because multiple processes occur simultaneously, many personnel and equipment occupy the working space, easily causing congestion and increasing the risk of collisions, crush injuries, and other accidents. For example, during parallel drilling and rock bolting, the operation of drilling and bolting machines may interfere with each other, and if operators are not attentive, safety accidents can easily occur. Some processes in parallel operations may conflict with safety regulations; for instance, to achieve parallel operations, safety distances might be shortened, or multiple processes might be conducted under poor ventilation conditions, all of which pose hidden dangers to construction safety.

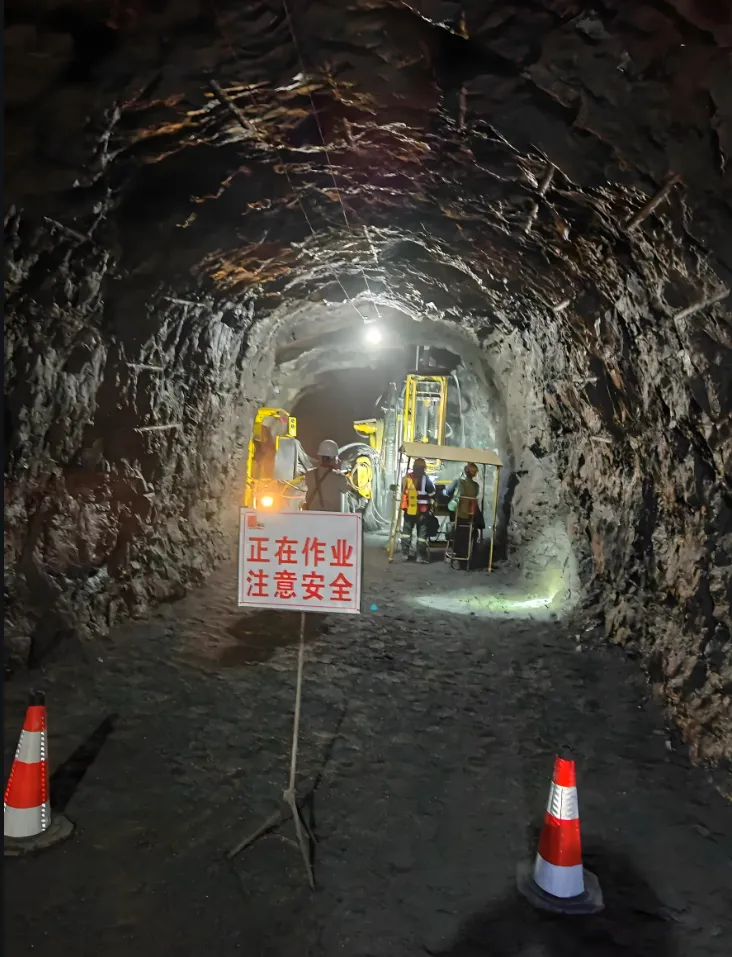

To address these safety challenges, strict safety measures must be implemented. After blasting, ensure safe distances in the work area and set clear warning signs to prevent personnel from entering dangerous zones. Strengthen equipment inspection and maintenance by regularly checking drilling and rock bolting machines to ensure good performance and safe operation. At the same time, enhance operator training to improve their safety awareness and operational skills so they can proficiently handle various emergencies. Develop detailed safety operation procedures for parallel operations, clearly defining safety requirements and precautions for each process, and require operators to strictly comply. Through these safety measures, the safety risks of parallel operations can be effectively reduced, ensuring safe and orderly construction.

Adaptability Comparison Between Parallel and Sequential Operations

Compared with sequential operations, parallel operations have obvious advantages in improving efficiency and productivity. In parallel operations, multiple processes proceed simultaneously, making full use of time and space, reducing waiting times between processes, thereby improving construction efficiency. In a flat drift tunneling project, when using parallel operations, drilling, rock bolting, and support can be carried out simultaneously, greatly shortening the construction cycle. Sequential operations require processes to be completed one after another, resulting in relatively lower time utilization efficiency. Parallel operations are especially suitable for mines with versatile workers who can skillfully operate multiple processes and flexibly allocate tasks, playing a greater role. The widespread adoption of pneumatic drilling supports also facilitates parallel operations, allowing drilling to be more flexibly conducted alongside other processes.

However, with the continuous emergence of large, efficient tunneling equipment, the advantages of sequential operations have gradually become apparent. For example, the appearance of drilling jumbos makes parallel drilling and bolting difficult to achieve. Drilling jumbos have high-efficiency and precise drilling capabilities, but due to their equipment structure and operation mode, rock bolting cannot be performed simultaneously during drilling. The emergence of high-efficiency drilling and bolting equipment has also greatly reduced the significance of some parallel operations. Sequential operations have the advantages of single-task focus and better working conditions, allowing workers to concentrate more during single-process tasks, reducing operational errors and improving work quality. Sequential operations facilitate the promotion of high-efficiency equipment, and by adopting advanced equipment, mechanization levels can be improved, further enhancing production efficiency.

In actual construction, the choice of operation mode should comprehensively consider various factors. The mechanization level of mining excavation is an important consideration. If the mechanization level is high and large, efficient excavation equipment is available, sequential operations may be more suitable; if the mechanization level is low and traditional small equipment is mostly used, parallel operations can better leverage the advantages. Equipment conditions also affect the choice of operation mode; different equipment suits different operation modes, so the appropriate mode should be selected based on equipment characteristics. Personnel quality is also a key factor. Mines with many versatile workers can better utilize parallel operations; for mines with workers having more specialized skills, sequential operations may be more appropriate. Currently, most mines under existing conditions, due to the still not very high mechanization level and productivity of excavation, the increasing number of versatile workers, and the widespread use of pneumatic rock drills, should primarily consider adopting multi-process parallel operations. When using parallel operations, efforts should be made to increase the parallel operation time of each process, expand the number of parallel processes while ensuring safe operations, and eliminate or reduce mutual interference caused by parallel operations to better leverage their advantages. However, the advantages of sequential operations should not be ignored; mines with suitable conditions should actively promote sequential operations and flexibly choose operation modes based on actual situations to achieve the best construction results.

Process Design and Efficiency Improvement of Multi-Process Cross Operations

- Essential Characteristics and Typical Processes of Cross Operations

The uniqueness of multi-process cross operations lies in breaking the traditional single-face sequential operation mode. When excavation work is carried out simultaneously on multiple faces, the main processes are cleverly interlaced across different faces. From a time perspective, at the same moment, different faces are performing different key processes; from a spatial perspective, each face becomes a stage for different processes, forming an efficient operation pattern of spatiotemporal interleaving.

Taking the operation process of three workers on three faces of the Fourth Excavation Team of Yunnan Tin Company as an example, their work arrangement is compact and orderly. At the start of the shift, an experienced driller quickly goes to Face A, which has just been mucked out by the previous shift, skillfully operates the drilling equipment, and begins drilling to prepare for subsequent blasting. Meanwhile, the other two workers are busy and orderly mucking on Face B, cooperating tacitly to quickly clear blasted rock and create conditions for the next round of drilling. When drilling on Face A finishes smoothly, mucking on Face B is basically completed simultaneously, reflecting their precise time control.

Immediately after, the driller originally on Face A quickly moves to Face B to continue drilling, while the other two workers go to Face A to carry out a series of key operations such as charging, blasting, and ventilation in an orderly manner. After ventilation begins, these two workers rush to Face C to load the blasted rock from the previous shift, making full preparations for the upcoming drilling. Thereafter, the entire operation process cycles repeatedly in this pattern, with processes on each face closely connected like gears in a precise clock, cooperating and running continuously.

The advantages of this cross-operation method are fully demonstrated in practice. Auxiliary operation time is greatly compressed because transitions between processes are efficient and smooth, with almost no unnecessary waiting time. Equipment utilization is greatly improved; a set of equipment can be flexibly allocated among 2 to 4 faces to complete tasks, avoiding equipment idling and waste. Personnel and equipment basically do not stop throughout the operation, with each link closely connected, forming a highly efficient operation system. Statistics show that using this method, average productivity can reach about 1 meter per (worker·shift), significantly improving efficiency compared to traditional methods.

- Significant Advantages and Management Points of Cross Operations

The advantages of cross operations are comprehensive and very significant. From the perspective of equipment utilization, since a set of equipment can be cycled among multiple faces, the usage frequency is greatly increased, reducing equipment purchase and maintenance costs. In some mines, purchasing a set of advanced mucking equipment requires a large investment; if used only on one face, the equipment idle time is long and the cost recovery period is extended. Using cross operations allows equipment to fully play its role on multiple faces, improving investment returns. Processes do not interfere with each other; each face operates in an orderly manner according to the established process sequence, avoiding efficiency loss caused by process conflicts. Workers on different faces focus on their assigned processes, becoming more skilled and improving work quality.

In terms of management, reasonable planning of work faces is crucial. The location and number of faces should be scientifically determined based on the mine's geological conditions and roadway layout, ensuring each face has sufficient working space and convenient access for equipment and personnel. Personnel scheduling also requires careful arrangement, allocating workers to faces and processes based on skill levels and experience to fully utilize individual strengths. Establishing a sound communication mechanism is key to ensuring smooth cross operations. Faces need to promptly share progress information, equipment status, safety hazards, and other important data to quickly make decisions and adjust operation plans. Real-time communication networks can be established using radios, mobile phones, and other devices to ensure timely information transmission.

Safety inspections are also an indispensable part of cross-operation management. Especially in key stages such as charging and blasting, safety checks at the work site must be strengthened to ensure operators strictly follow safety procedures and prevent accidents caused by improper operations. Equipment should be regularly inspected to ensure safety and reliability. Before charging, the quality and quantity of explosives and the performance of charging equipment must be carefully checked; before blasting, the warning range must be reasonably set and all personnel evacuated to safe areas.

- Applicable Scenarios and Risk Prevention of Cross Operations

Cross operations have specific applicable scenarios in mining engineering, especially suitable for multi-head excavation projects. When a mine needs to develop multiple roadways simultaneously and has many faces but limited equipment, cross operations can fully exploit the potential of personnel and equipment, improving construction efficiency. In some large mines' deep mining projects, multiple roadways need to be excavated simultaneously to meet ventilation, transportation, and other needs. Using cross operations under limited equipment conditions can accelerate excavation progress and ensure normal mine production.

However, cross operations also involve certain risks during implementation that require high attention and control. Different faces may affect each other; for example, blasting on one face may threaten the safety of personnel and equipment on adjacent faces. Frequent equipment movement among multiple faces also increases the probability of equipment failure and safety accidents. To address these risks, detailed cross-operation procedures and safety regulations must be formulated. The operation sequence and safety requirements of each process on different faces should be clearly defined so operators know how to act under various conditions, avoiding accidents caused by improper operations.

Strengthening equipment maintenance and management is also crucial. Establish a system for regular equipment inspection and maintenance to ensure good performance during movement and use, reducing equipment failures. Before moving equipment, conduct a comprehensive inspection to ensure all performance indicators are normal; during equipment use, closely monitor operational status to promptly detect and address faults. Provide targeted training for operators to improve their familiarity with cross-operation processes and safety awareness, enhancing emergency response capabilities. Training content can include safety operation procedures, emergency handling methods, and equipment operation skills, combining theoretical explanations and practical drills to ensure operators truly master relevant knowledge and skills. Only through comprehensive risk prevention measures can the safety and efficiency of cross-operation construction be guaranteed, ensuring the smooth progress of mining engineering.

Comprehensive Selection and Safety Assurance of Drift Excavation Operation Methods

- Key Influencing Factors in the Selection of Operation Methods

In drift excavation operations in mines, choosing the appropriate operation method is crucial and requires comprehensive consideration of multiple factors. Geological conditions are one of the primary key factors to consider, as different geological structures and rock characteristics significantly impact the operation method. In mines with complex geological conditions and high rock hardness, using traditional single-process sequential operations may lead to low excavation efficiency and fail to meet production demands. In such cases, multi-process parallel or cross-operation methods may be more suitable, as they can fully utilize time and space to improve excavation efficiency. However, these methods also demand higher requirements for equipment and safety measures, necessitating advanced drilling, rock loading equipment, and comprehensive safety protection facilities to ensure construction safety under complex geological conditions.

The level of mechanization and equipment configuration are also important factors influencing the choice of operation methods. For mines with high mechanization levels and large, efficient excavation equipment, sequential operations may better leverage the equipment's advantages. For example, mines equipped with advanced drilling jumbos, due to the operational characteristics of the drilling jumbo, find it difficult to perform other processes simultaneously during drilling; sequential operations can ensure efficient equipment operation, improving construction quality and efficiency. Conversely, for mines with lower mechanization levels and relatively simple equipment, parallel and cross-operations can make full use of personnel initiative through reasonable process arrangements, compensating for equipment shortcomings and increasing excavation speed.

The skill level of personnel is also not to be overlooked. Teams with many versatile workers can demonstrate greater advantages in parallel and cross-operations. They can skillfully master multiple process operation skills and flexibly switch between different processes to achieve efficient multi-process coordination. In the "Top Ten Parallel" operations, versatile workers can simultaneously undertake tasks such as drilling, support, and track laying, greatly improving construction efficiency. For teams with workers having more specialized skills, sequential operations may be more suitable, allowing workers to focus on processes they are familiar with, reducing operational errors and improving work quality.

Safety requirements are the core element throughout the selection of operation methods. Regardless of the method adopted, construction safety must be ensured. When choosing operation methods, safety factors must be fully considered to avoid neglecting safety in pursuit of efficiency. For safety issues that conflict with the "Safety Regulations," a particularly cautious attitude should be maintained, and effective safety measures should be implemented, such as enhancing ventilation, setting safety warning signs, and conducting regular equipment inspections to ensure safe construction.

- Construction of a Full-Process Safety Assurance System

Safety is the top priority in drift excavation work. Establishing a comprehensive safety assurance system covering pre-operation, during operation, and post-operation is key to ensuring smooth construction.

Preparation before operation is crucial. First, conduct thorough geological exploration to understand the mine's geological structure, rock characteristics, groundwater conditions, and other information, providing a basis for formulating reasonable construction plans and safety measures. Conduct comprehensive inspections of ventilation and drainage systems to ensure their normal operation, creating a good working environment for operators. The ventilation system must provide sufficient airflow to expel harmful gases and supply fresh air; the drainage system must promptly remove groundwater to prevent water accumulation from affecting construction. Perform comprehensive maintenance and inspection of equipment, checking performance and completeness of parts to ensure safe and reliable operation during work. Provide safety training and technical briefings to operators, familiarizing them with work processes and safety risks, mastering safety operation procedures and emergency handling methods. Through case analysis and on-site demonstrations, enhance operators' safety awareness and operational skills, enabling them to consciously comply with safety regulations and correctly respond to various emergencies during work.

Safety management during operation is the core link to ensuring construction safety. Strengthen on-site safety management by setting clear safety signs and protective facilities, such as safety isolation zones in parallel operation areas to prevent interference between personnel and equipment during work, avoiding collisions, crush injuries, and other accidents. Regularly inspect the working face for loose rocks, water inrush, and other conditions, promptly addressing safety hazards. Use methods like tapping and sounding to check the stability of the roof and ribs, promptly remove loose rocks; monitor water inrush and implement effective drainage measures to keep the working face dry. Strictly enforce safety operation procedures for blasting and rock loading processes; blasting must strictly follow designed parameters to ensure blasting effect and safety; rock loading must adhere to equipment operation specifications to avoid injuries. Strengthen supervision and management of operators to ensure strict compliance with safety regulations and prevent violations.

Post-operation finishing work should not be neglected. Perform maintenance and upkeep of equipment used during operations, including cleaning, lubrication, and inspection, timely replacing worn parts to ensure equipment can operate normally in the next operation. Clean the working face, removing residual rocks and debris to create good conditions for the next shift. Conduct a safety summary of the current operation, analyze safety issues and deficiencies encountered, propose improvement measures, and continuously improve the safety assurance system. By constructing a full-process safety assurance system, safety risks in drift excavation operations can be effectively reduced, ensuring construction safety and the safety of personnel and property.