Main flat drift, main inclined shaft, auxiliary flat drift, auxiliary inclined shaft comprehensive development - Black King Kong report

Preface

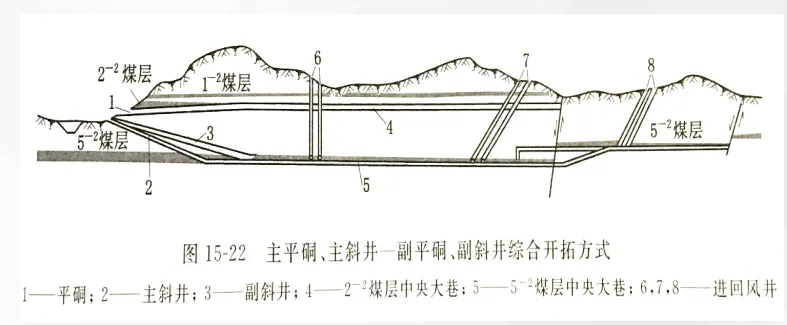

In the field of coal mining, the choice of mine field development method is crucial for mine production efficiency, economic benefits, and safety. As a development method that combines different forms of mine openings based on specific coal seam mining conditions, integrated development has been increasingly widely used in China in recent years. Among them, the main flat roadway, main inclined shaft - auxiliary flat roadway, auxiliary inclined shaft integrated development method, due to its unique advantages and adaptability, has shown significant technical and economic effects under specific geological and mining conditions. This development method fully integrates the advantages of flat roadway development and inclined shaft development, providing a strong guarantee for efficient and safe coal mining.

(Image from MOOC China University of Mining and Technology Mining Engineering Tu Shihao, Fang Zhijun, Zheng Xigui, Wang Xufeng, Peng Hongge, Yuan Yong)

Functions and characteristics of each mine opening

Main flat roadway

As an important part of mine development, the main flat roadway has unique advantages. Its roadway longitudinal axis is approximately parallel to the horizontal plane, directly connected to the ground, and undertakes the main transportation tasks of the mine. In terms of transportation, the main flat roadway fully demonstrates its high efficiency. Due to its horizontal characteristics, coal and other materials can be transported by gravity, without the need for additional lifting equipment, which greatly reduces the transportation links and the use of transportation equipment, reduces transportation costs, and improves transportation efficiency. In some mines that use main flat roadway development, after the coal is mined from the underground working face, it can be directly transported to the ground through equipment such as belt conveyors. The entire transportation process is simple and smooth, reducing time loss and equipment failure risks caused by lifting and transshipment.

At the same time, the main flat roadway also has significant advantages in drainage. Because it has a certain outward slope, usually maintained at 3-5°, the underground water can naturally flow out of the well under the action of gravity, without the need to set up complex pump rooms and water tanks and other drainage chambers in the roadway, reducing the amount of well shaft engineering and the investment in drainage equipment, reducing drainage costs, and also helping to prevent water disasters and improve mine safety.

In the development of the upper coal seam, the main flat roadway plays a core role. As the main transportation channel, it continuously transports the coal mined from the upper coal seam to the ground, providing strong support for the mine's coal sales and production operations. At the same time, the main flat roadway also undertakes important tasks such as material transportation, gangue transportation, personnel transportation, ventilation, and pipeline laying, and is a key channel for ensuring normal mine production.

Main inclined shaft

The longitudinal axis of the main inclined shaft roadway is at a certain angle to the horizontal plane and is directly connected to the ground. When the main inclined shaft is equipped with a belt conveyor, it has many outstanding characteristics in coal transportation. The belt conveyor has a strong transportation capacity and can meet the transportation needs of large-scale coal mining. In some large mines, the transportation capacity of the main inclined shaft belt conveyor can reach thousands or even tens of thousands of tons per hour, which can efficiently and quickly transport the coal mined underground to the ground, greatly improving the mine's production efficiency.

This transportation method has the advantage of strong continuity, which can realize uninterrupted coal transportation and avoid time waste and low efficiency caused by intermittent transportation. The belt conveyor also has the characteristics of high automation, and can realize remote monitoring and operation through an advanced control system, reducing manual intervention, reducing labor intensity, and improving the safety and reliability of transportation.

The use of belt conveyors in the main inclined shaft also has a positive significance for mine deepening. As mining continues to deepen, mine deepening is needed to obtain more coal resources. In this case, the belt conveyor transportation system can be relatively easily modified and extended to adapt to the transportation needs after mine deepening, providing convenient conditions for the sustainable development of the mine.

Auxiliary flat roadway and auxiliary inclined shaft

The auxiliary flat roadway is also a horizontal roadway connected to the ground, mainly undertaking auxiliary transportation tasks in mine production. It is responsible for transporting materials, equipment, and other materials needed underground to various work locations, providing material support for normal mine production. The auxiliary flat roadway also plays an important role in ventilation, providing fresh air flow underground, discharging foul air, improving the underground working environment, and ensuring the physical health and safe production of operating personnel.

The auxiliary inclined shaft, as an inclined roadway directly connected to the ground, plays a key role in auxiliary hoisting in the mine. It is mainly used for hoisting personnel, equipment, and gangue, ensuring that personnel can safely and quickly enter and exit the mine, equipment can be transported to the underground work location in time, and gangue can be transported to the ground in time. The auxiliary inclined shaft also undertakes ventilation tasks, providing sufficient fresh air underground to meet the ventilation needs of underground operations. In some mines, the auxiliary inclined shaft also serves as a safety exit, providing an important passage for personnel evacuation and escape in emergencies, ensuring the safety of personnel's lives.

Advantages of integrated development analysis

Adaptability to complex geological conditions

This integrated development method of main flat roadway, main inclined shaft - auxiliary flat roadway, auxiliary inclined shaft can excellently adapt to complex and changeable geological conditions and give full play to the unique advantages of various mine openings. The upper coal seam is usually buried relatively shallow, and flat roadway development has significant advantages. The construction of flat roadway development is relatively simple, the well construction speed is fast, and coal mining and transportation can be quickly realized. Due to the horizontal characteristics of the flat roadway, gravity self-flow transportation can be used during transportation, reducing the use and energy consumption of transportation equipment and reducing transportation costs. At the same time, the drainage system of the flat roadway is simple, and the water can flow out naturally, without complex drainage equipment and facilities, improving the safety and reliability of the mine.

If the lower coal seam is buried deeper or the occurrence conditions are more complex, inclined shaft development is more suitable. Inclined shaft development is relatively simple in terms of shaft sinking technology, construction equipment, shaft equipment and installation technology, etc., with fast excavation speed, short well construction period, early coal production, and low initial investment. In some mines, the lower coal seam adopts inclined shaft development, which can quickly open up the passage to the coal seam, realize coal mining in advance, and bring economic benefits to the enterprise.

The inclined shaft can also supplement geological data during the process of advancing along the coal seam, providing more accurate geological information for subsequent mining. For deep coal seams, the inclined shaft uses belt conveyors for transportation, which can realize the continuity and automation of underground transportation, and the lifting capacity is not limited by the depth of the shaft, which can meet the high-yield and high-efficiency mining needs of large mines. This integrated development method flexibly selects flat roadway and inclined shaft development according to the occurrence conditions of different coal seams, giving full play to their respective advantages, improving the adaptability to complex geological conditions, and laying a solid foundation for efficient mine mining.

Improve mining efficiency

From the perspectives of transportation, ventilation, and hoisting, the comprehensive development method of main haulage level and main incline - auxiliary haulage level and auxiliary incline has a significant effect on improving mining efficiency. In terms of transportation, the main haulage level utilizes gravity flow transportation of coal, which is efficient and cost-effective. After coal is mined from the underground working face, it is directly transported to the ground via conveyor belts and other equipment along the slope of the main haulage level, reducing transportation links and equipment, and improving transportation efficiency. The main incline is equipped with belt conveyors, with large transportation capacity, strong continuity, and high degree of automation. It can quickly and continuously transport a large amount of coal from underground to the ground, meeting the needs of large-scale production in the mine.

In terms of ventilation, the auxiliary haulage level and auxiliary incline undertake the important task of providing fresh air to the underground. They, together with the main haulage level and main incline, constitute a reasonable ventilation network, ensuring that all work sites underground have sufficient fresh air, exhaust foul air, improve the underground working environment, and ensure the physical health and safety production of the workers. A reasonable ventilation system can also effectively reduce the concentration of gas, reduce the risk of gas accidents, and provide a guarantee for the safe production of the mine.

In the hoisting aspect, the auxiliary incline is mainly used for hoisting personnel, equipment, and gangue. Its hoisting method can ensure that personnel can enter and exit the mine safely and quickly, equipment can be transported to the underground work site in time, and gangue can be transported to the ground in time. When hoisting personnel, the auxiliary incline uses special hoisting equipment, such as personnel cars, to ensure the safety and comfort of personnel. When hoisting equipment and gangue, appropriate hoisting equipment and methods are selected according to the weight, volume, and other characteristics of the equipment and gangue to improve hoisting efficiency. This comprehensive development method effectively improves the mining efficiency of the mine and ensures high-yield and high-efficiency production of the mine by optimizing the design and operation of each link.

Reduce Costs and Risks

The comprehensive development method of main haulage level and main incline - auxiliary haulage level and auxiliary incline also has obvious advantages in reducing costs and risks. In terms of engineering volume and investment, this development method can reasonably arrange shafts and tunnels according to the coal seam occurrence conditions and mining requirements, reducing unnecessary shaft and tunnel engineering volume. The upper coal seam adopts haulage level development, avoiding the large amount of engineering and investment required for sinking shafts or inclines. The lower coal seam adopts incline development, which, compared with shaft development, has a smaller shaft excavation engineering volume, requires less equipment and materials, and has lower investment costs.

This development method can also reduce the construction scale and investment of ground industrial facilities. Because the construction and equipment of haulage levels and inclines are relatively simple, the supporting ground industrial facilities are also relatively simple, reducing construction costs. In some mines that adopt this comprehensive development method, the ground industrial square has a smaller area and compact facility layout, reducing land acquisition costs and facility construction costs.

In response to emergencies, this development method also has good safety protection. Multiple shafts and tunnels serve as safety exits, providing more options for personnel evacuation and escape in case of fire, gas explosion, and other emergencies, improving the survival rate of personnel. Different shafts and tunnels cooperate with each other in ventilation, drainage, and other aspects, enhancing the mine's disaster resistance. When a ventilation failure occurs in a certain shaft or tunnel, other shafts and tunnels can promptly supplement fresh air to ensure underground ventilation safety. When the mine water inflow suddenly increases, the drainage systems of various shafts and tunnels can work together to promptly drain the water, preventing water disasters. This comprehensive development method provides strong support for the sustainable development of the mine by reducing costs and improving safety.

Application Case Analysis

Taking Panjiang Huopu Mine as an example, the mine adopted the comprehensive development method of main haulage level and main incline - auxiliary haulage level and auxiliary incline during the development process and achieved good results. The geological conditions of Panjiang Huopu Mine are complex, and the coal seam occurrence conditions vary greatly. The upper coal seam is relatively shallow, while the lower coal seam is relatively deep. In view of this situation, the mine decided to adopt a comprehensive development method.

During the development process, the upper coal seam was developed using the main haulage level. The main haulage level undertakes the main transportation task of coal in the upper coal seam, and its gravity flow transportation method greatly improves transportation efficiency and reduces transportation costs. At the same time, the main haulage level also takes into account material transportation, gangue discharge, personnel passage, air intake, and pipeline laying, providing all-round support for the mining of the upper coal seam.

For the lower coal seam, Panjiang Huopu Mine used the main incline and auxiliary incline for development. The main incline is equipped with belt conveyors, realizing efficient coal transportation and meeting the needs of large-scale mining of the lower coal seam. The auxiliary incline is mainly used for hoisting personnel, equipment, and gangue, ensuring the transportation of materials and personnel for the mining of the lower coal seam.

During the development process, Panjiang Huopu Mine also encountered some problems. During the construction of the main incline, due to the complex geological conditions, local rock breakage and water inrush occurred, which brought certain difficulties to the construction. In order to solve these problems, the mine adopted a series of effective measures. In the rock breakage section, advanced support technologies such as anchor net spray support and anchor cable support were adopted to ensure the stability of the shaft. In response to the water inrush problem, the construction of the drainage system was strengthened, the number and drainage capacity of drainage equipment were increased, and the accumulated water in the shaft was promptly drained, ensuring the smooth progress of the construction.

In terms of ventilation system construction, there were also some challenges. Because the mine adopts a comprehensive development method, the ventilation route is long, and the ventilation resistance is large. In order to ensure underground ventilation safety, the mine optimized the ventilation system design, increased the power and number of ventilation equipment, reasonably adjusted the ventilation network, reduced ventilation resistance, and ensured the ventilation needs of various work sites underground.

By adopting the comprehensive development method of main haulage level and main incline - auxiliary haulage level and auxiliary incline, Panjiang Huopu Mine has achieved significant results in actual production. The mine's production efficiency has been greatly improved, coal production has increased year by year, and the enterprise has achieved good economic benefits. The safety of this development method has also been fully demonstrated. Multiple safety exits and a reasonable ventilation and drainage system effectively reduce the risk of accidents and ensure the safety of employees' lives. The successful experience of Panjiang Huopu Mine provides useful reference for other mines with similar geological conditions, proving the feasibility and superiority of this comprehensive development method in practical application.

Construction Points and Precautions

Construction Sequence and Coordination

In the construction process of the comprehensive development of the main haulage drift, main incline - auxiliary haulage drift, auxiliary incline, reasonable arrangement of the construction sequence is crucial. Usually, the construction of the main haulage drift is carried out first, because the construction of the main haulage drift is relatively simple, the well construction speed is fast, and it can quickly form the mine's transportation channel, providing convenience for subsequent construction and coal mining. Simultaneously with the construction of the main haulage drift, the construction of the main incline and auxiliary haulage drift can be carried out in a timely manner according to the project progress and construction conditions. The construction of the main incline should pay attention to the slope and support of the shaft, ensuring the stability and construction safety of the shaft. The construction of the auxiliary haulage drift should focus on the connection with the main haulage drift and other drifts, ensuring the smooth flow of auxiliary transportation and ventilation systems.

In the construction process, the coordination and cooperation between various drifts are the key to ensuring the smooth progress of the project. Effective communication mechanisms need to be established between the construction teams of different drifts to exchange information on construction progress, technical difficulties, and safety issues in a timely manner. In the connection process between shaft construction and bottom roadway construction, the construction sequence and time should be reasonably arranged to ensure that the two can be smoothly connected, avoiding construction conflicts and delays. In the construction of the transportation system, the transportation capacity and transportation methods of the main haulage drift, main incline, and auxiliary haulage drift should be considered, and transportation equipment should be reasonably configured to ensure the smooth transportation of coal and materials. The construction of the ventilation system also requires close cooperation between various drifts. According to the layout and ventilation needs of the drifts, ventilation equipment and ventilation pipelines should be reasonably arranged to ensure good ventilation underground. By reasonably arranging the construction sequence and strengthening the coordination and cooperation between various drifts, construction efficiency can be improved, project quality can be guaranteed, and the mine can be built and put into production on time.

Safety Protection Measures

During construction, safety risks cannot be ignored, and effective preventive measures must be taken. Gas is one of the common safety hazards in coal mining, and it is flammable and explosive. To prevent gas accidents, a complete gas monitoring system needs to be established, and gas sensors should be installed at various work sites and key ventilation points underground to monitor gas concentration in real time. Once the gas concentration exceeds the safety standard, an alarm should be issued immediately, and corresponding measures should be taken, such as strengthening ventilation and stopping work, to reduce the gas concentration and ensure operational safety. In some high-gas mines, gas extraction technology is also used to extract the gas from the coal seam in advance, reduce the gas content, and reduce the risk of gas accidents.

Water inrush accidents are also major safety risks in coal mine construction, which may pose a serious threat to human life and mine facilities. To prevent water inrush accidents, geological exploration work needs to be strengthened to understand the hydrogeological conditions in the mining area in detail, including the distribution of aquifers, water level changes, the thickness and stability of aquicludes, etc. During construction, strictly follow the principle of "exploration if there is doubt, exploration before excavation", and use advanced geophysical exploration and drilling techniques to detect the geological conditions ahead, and find potential water inrush hazards in advance. When signs of water inrush are found, construction should be stopped immediately, and effective water plugging and drainage measures should be taken, such as grouting water plugging and increasing drainage equipment, to prevent water inrush accidents.

Roof accidents are also one of the safety risks that need to be focused on during construction. During roadway excavation, due to rock fragmentation, the development of joints and fissures, etc., roof collapse is easy to occur. To prevent roof accidents, reasonable support methods should be selected according to different geological conditions and roadway cross-sectional dimensions, such as anchor net spray support, anchor cable support, and frame support. During construction, strengthen the monitoring of the roof, timely find the deformation and loosening of the roof, and take corresponding reinforcement measures, such as supplementing anchor rods and anchor cables, to ensure the stability of the roof.

In order to improve the safety awareness and emergency response capabilities of construction personnel, safety education and training need to be strengthened. Regularly organize construction personnel to participate in safety knowledge training and emergency drills, so that they are familiar with various safety risk prevention measures and emergency handling methods. In the training, actual cases can be combined to explain the causes and hazards of safety accidents, and improve the safety vigilance of construction personnel. Through strengthening safety education and training, safety accidents caused by human factors can be effectively reduced, and the life safety of construction personnel and the safe production of mines can be guaranteed.

Overcoming Technical Difficulties

Construction under complex geological conditions often encounters many technical difficulties, and targeted solutions need to be adopted. Shaft support is a key link in construction, especially under geological conditions such as soft rock layers and fractured zones, the stability of the shaft faces severe challenges. For soft rock layers, because of their low strength, high plasticity, and easy deformation, conventional support methods are often difficult to meet the requirements. In this case, the combined support technology of anchor net spray can be used, through the anchoring effect of anchor rods, the strengthening effect of steel wire mesh, and the sealing effect of sprayed concrete, to jointly improve the stability of the surrounding rock. In some soft rock layers, anchor cable support technology can also be used, and anchor cables can penetrate into stable rock layers to provide greater anchoring force and enhance the support effect.

For fractured zones, due to rock fragmentation and the development of joints and fissures, situations such as slabbing and roof collapse are easy to occur. During construction in fractured zones, advanced support technology, such as advanced anchor rods and advanced small guide pipes, can be used to consolidate the fractured zone before excavation to prevent rock collapse. Grouting reinforcement technology can also be used to inject cement slurry or chemical slurry into the fissures of the fractured zone, so that the fractured rocks are bonded together, improving their integrity and strength.

Steep incline construction is also a technical difficulty. During construction, problems such as hoisting, transportation, and drainage need to be solved. In terms of hoisting, due to the large slope of the incline, the hoisting equipment needs to have sufficient hoisting capacity and stability. High-power hoisting winches and high-strength steel wire ropes can be used to ensure the safe hoisting of personnel, equipment, and materials. In terms of transportation, in order to improve transportation efficiency, continuous transportation equipment such as belt conveyors can be used, and the parameters of the equipment can be reasonably adjusted according to the slope and length of the incline. In terms of drainage, due to the certain slope of the incline, the water inflow is easy to accumulate at the bottom of the shaft. To solve the drainage problem, a drainage pump room and water tank can be set up at the bottom of the shaft, and a sufficient number and drainage capacity of drainage equipment can be installed to remove the water inflow in time. The segmented drainage method can also be used to drain the water inflow in segments, reducing the burden on the drainage equipment. By adopting these targeted technical measures, the technical difficulties of construction under complex geological conditions can be effectively overcome, and the smooth progress of the project can be ensured.

Summary

The comprehensive development method of the main haulage drift, main incline - auxiliary haulage drift, auxiliary incline is a scientific, efficient, and safe mining area development method. It cleverly combines the advantages of haulage drift development and incline development, successfully solving the problems of coal mining under complex geological conditions. This development method has excellent performance in adapting to complex geological conditions, improving mining efficiency, reducing costs and risks, and providing a solid guarantee for the high-yield, high-efficiency, and sustainable development of the mine.

In practical applications, successful cases such as Panjiang Huopu Mine have fully demonstrated the feasibility and superiority of this comprehensive development method. Through in-depth analysis of these cases, we can clearly see that under reasonable construction organization and effective safety protection measures, this development method can be implemented smoothly and achieve good economic and social benefits.

(This article refers to the courseware of Mining Engineering from China University of Mining and Technology on MOOC, by Tu Shihao, Fang Zhijun, Zheng Xigui, Wang Xufeng, Peng Hongge, and Yuan Yong.)