(Collection) Goaf survey content, methods, key points, and difficulties——Black King Kong broadcast

The survey scope mainly includes goafs formed by mining in the mining right area that may cause disasters such as collapse and water inrush (goafs left by open-stoping, hanging goafs by caving, and un-roofed goafs by filling), goafs left by historical mining (old goafs), and abandoned roadways.

The main contents of the goaf survey are as follows:

1. Time, cause, location, spatial morphology, and treatment methods (blocking, caving, filling, or isolation) of goafs;

2. Location, scope, and surrounding water distribution of abandoned roadways;

3. Water accumulation area and volume in goafs;

4. Distribution of surrounding rock and soil masses and structures;

5. Surface subsidence deformation, collapse range, and crack distribution of goafs.

Goaf surveys should collect goaf data within the mining right area and within 50m outside the mining right area, and analyze the main contents:

1. Mining history, current situation, and planning;

2. Approximate location of goafs, treatment methods, water accumulation, distribution of surrounding rock and soil masses and structures, physical and mechanical properties of surrounding rock and soil masses and internal filling materials, surface subsidence and collapse, location and deformation and damage of surface buildings and structures, and internal filling of goafs;

3. Approximate location, possible distribution range, and surrounding water conditions of abandoned roadways;

4. Data on historically left loose material yards (dumping grounds, tailings ponds, etc.), landslides, debris flows, and historical floods.

Main contents of field survey and mapping of goafs:

1. Surface features such as mine topography and geomorphology, distribution range of surface subsidence and collapse, location and distribution of cracks, location of surface buildings and structures, and opening location of abandoned roadways;

2. Location of goafs and abandoned roadways that can be safely approached, approximate distribution of lithology and structure, water discharge conditions, and treatment methods;

3. Roof support conditions of implemented goaf special governance projects,

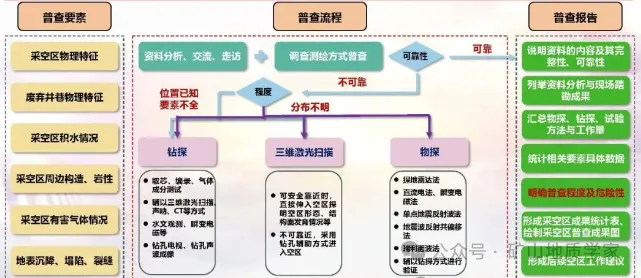

Goaf surveys should evaluate the completeness and reliability of the actual engineering quantity-supported measured data and collected goaf-related element data based on the analysis of existing data and field survey and mapping. If the relevant data is complete and reliable, a goaf survey chapter report can be compiled; otherwise, field exploration, testing, and experiments should be carried out.

Goafs that affect the safe production of the production area and planning area should be explored using geophysical prospecting and drilling.

When geophysical prospecting methods are used for goaf surveys, the geophysical prospecting scope should include the preliminarily inferred goaf and the extension area. The preliminarily inferred goaf is comprehensively delineated based on collected data and field surveys, and the extension area is extended outward from the boundary of the preliminarily inferred goaf by no less than 100m. Geophysical prospecting methods should meet the following requirements:

1. For goafs with unknown distribution that affect the production area, no less than 2 geophysical prospecting methods should be used for detection; for goafs in the production area whose location is known but whose elements are not fully understood, no less than 1 geophysical prospecting method should be used for detection.

2. For unknown goafs in the planning area, no less than 1 geophysical prospecting method should be used for detection.

If ground geophysical prospecting conditions are available, the geophysical prospecting method should be determined in combination with geological and topographic and geomorphic conditions, goaf and stratum physical property characteristics, and interference source characteristics:

1. For goafs with a burial depth less than or equal to 50m, ground penetrating radar, seismic exploration, microtremor, high-density resistivity, variable electromagnetic, or microgravity geophysical prospecting methods should be selected;

2. For goafs with a burial depth greater than 50m and less than or equal to 150m, microtremor, seismic exploration, transient electromagnetic, or high-density resistivity geophysical prospecting methods should be selected;

3. For goafs with a burial depth greater than 150m, microtremor, seismic exploration, transient electromagnetic, controlled-source audio magnetotellurics, or direct current geophysical prospecting methods should be selected.

If mine geophysical prospecting conditions are available, the geophysical prospecting method should be determined based on the detection purpose, detection distance, and geological conditions, and should meet the following requirements:

1. Mine geophysical prospecting should select transient electromagnetic methods, direct current methods, ground penetrating radar methods, elastic wave methods (single-point seismic reflection wave methods, seismic wave reflection common offset methods, Rayleigh surface wave methods), or ultrasonic detection geophysical prospecting methods;

2. Mine geophysical prospecting should focus on tracking the geophysical anomaly areas interpreted by ground geophysical prospecting.

The layout of the geophysical prospecting network and its maximum network density should meet the following requirements:

1. The layout of geophysical prospecting lines should be perpendicular or at a large angle to the goaf to be investigated, and the length of the survey lines should cover the extension area.

2. The grid spacing of ground geophysical prospecting methods should be no more than 10m within the preliminarily inferred goaf and no more than 20m in the extension area; the grid spacing should be no more than the limit exposure size of the goaf obtained from the analysis of empirical methods for goaf stability, generally no more than 10m, and the grid spacing and point spacing should be appropriately reduced for possible narrow goafs.

3. The grid density of mine geophysical prospecting methods should generally meet the following requirements:

Ground penetrating radar method: High-precision continuous measurement should be carried out, with no less than 3 survey lines for roadway detection, and the point spacing should be no more than 2m; there should be no less than 2 survey lines for the heading face, and the angle should be no more than 45°.

Suspected goafs delineated by geophysical prospecting should be verified by ground drilling and down-hole drilling, and the geophysical prospecting results should be verified based on the drilling or excavation exposure conditions. Verification boreholes should meet the following requirements:

1. The layout of verification boreholes should be comprehensively determined based on existing data and geophysical prospecting results, and verification boreholes should be located within the preliminarily inferred goaf.

2. The number of verification boreholes should be determined comprehensively based on the scope of the suspected goaf, geological conditions, orebody occurrence, and three-dimensional spatial distribution. At least one verification borehole should be arranged for each typical suspected goaf. For geophysical anomaly zones with buildings (structures) above, the number of verification boreholes should be increased.

3. Verification boreholes should be drilled into the goaf or to a position no less than 5m through the suspected goaf.

4. When using underground drilling for verification, verification boreholes should be arranged in the direction of the suspected goaf from the advancing roadway. The boreholes should also meet the provisions and requirements of AQ 2061 regarding advance grouting and drainage.

5. The construction platform for verification boreholes in open-pit mines should be designed at least two open-pit bench heights above the suspected goaf, and should be greater than twice the ultimate safe thickness of the goaf.

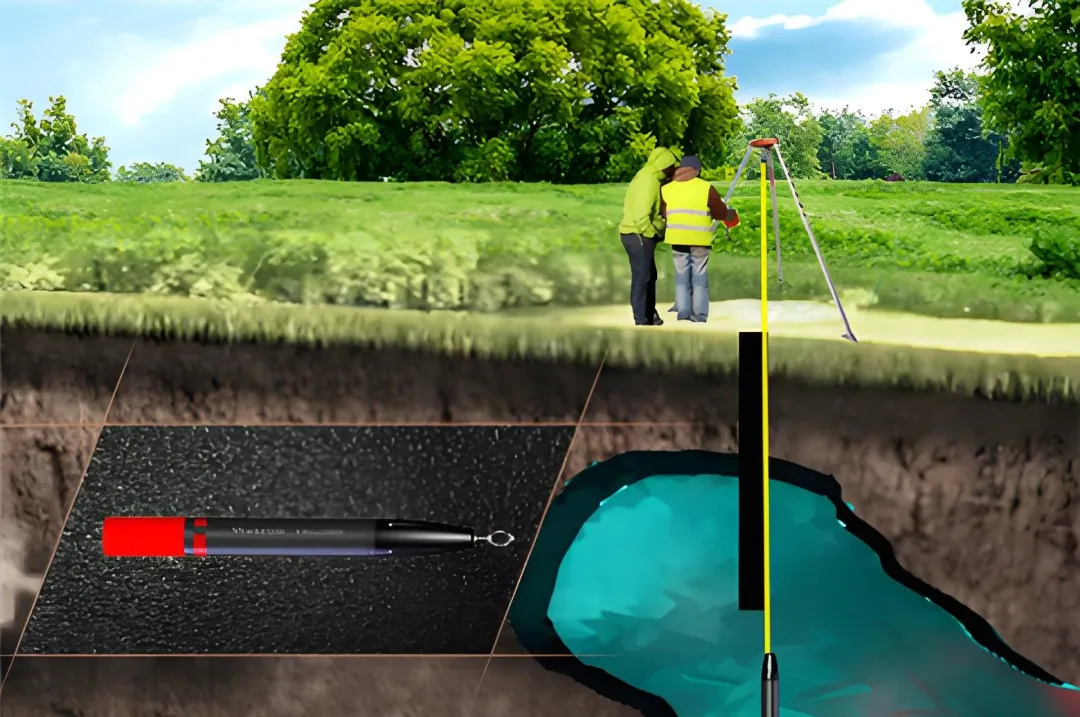

Verification drilling of goafs and goafs discovered through drilling should meet the following requirements:

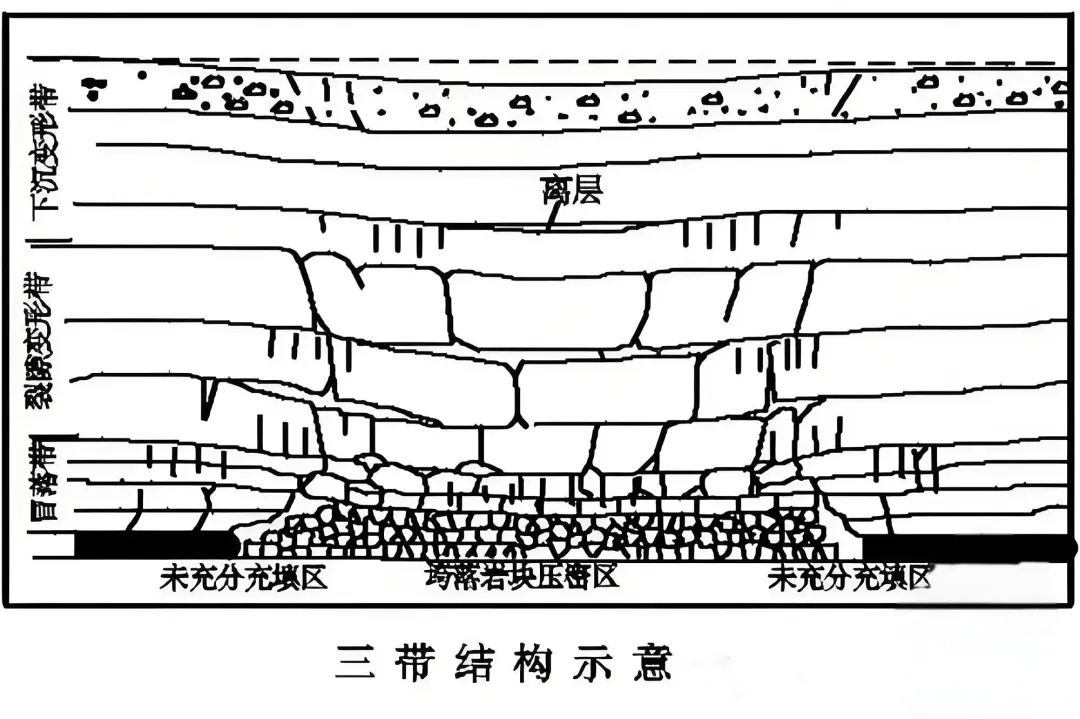

1. The goaf boundaries, hanging wall, or collapse conditions should be verified by analyzing data such as drilling depth, core recovery rate, drop drilling, stuck drilling, buried drilling, air suction, water volume, water level changes, fire (smoke, gas emission), etc.;

2. Three-dimensional laser scanning, sonar, borehole seismic wave CT, borehole electromagnetic wave CT, borehole ground-penetrating radar, or borehole television should be used to detect the boundaries and shape of the goaf;

3. Borehole hydrological observation, borehole resistivity CT, borehole variable electromagnetics, or borehole induced polarization methods should be used to detect the water accumulation in the goaf;

4. For goafs requiring stability analysis, coring, inclination measurement, drilling logging, RQD, roughness of structural planes, and weathering degree statistics should be carried out.

For goafs that affect the safe production of the production area, the following elements should be investigated and their hazards analyzed:

1. The formation time, cause, location, exposed area, volume, and treatment method of the goaf, to understand the basic situation of the goaf;

2. The location, scope, and surrounding water distribution of abandoned roadways, to understand the basic situation of abandoned roadways;

3. The water accumulation area and volume in the goaf, to analyze the possibility of water seepage in the goaf;

4. The lithology and structural distribution around the goaf, to analyze the stability of the goaf itself and the risks of goaf collapse, slope instability, and landslides;

5. The surface settlement deformation, collapse range, and crack distribution of the goaf, to analyze the replenishment of surface water to the goaf and the risks of goaf collapse, well flooding, slope instability, and landslides.

For goafs that affect the safe production of the planning area, the following elements should be basically investigated and their hazards analyzed:

1. The location and approximate spatial state of the goaf, to understand the basic situation of the goaf;

2. The location, scope, and possibly existing surrounding water bodies of abandoned roadways, to understand the basic situation of abandoned roadways;

3. Whether there is water accumulation in the goaf, to analyze its threat to the future safe production of the planning area,

Goaf Investigation Conclusions

1. The goaf investigation conclusions should include the workload of data collection and analysis, on-site investigation, investigation results, investigation degree, hazard analysis, and prevention and control measures suggestions,

2. Prepare goaf results statistical tables and abandoned roadway results statistical tables

3. Draw goaf investigation results maps.

Goaf Investigation Key Points

1. Does the investigation scope meet the requirements?

2. What are the types of goafs? Does the goaf affect the safe production of the production area and planning area?

3. Are the investigation elements of the goaf comprehensive?

4. Are the investigation methods comprehensive and targeted?

5. Do the specific parameters of the investigation methods meet the standard requirements?

6. Has the investigation hazard been thoroughly analyzed?

7. Are the investigation conclusions complete and reliable?

8. Are the investigation charts filled out completely and correctly?

Difficulties in Goaf Investigation

1. Credibility and accuracy of geophysical exploration?

2. For the first time systematically proposing the constraining application of detection instruments in metal and non-metal mines, the level of application units is uneven; strong geological interference and drastic changes in physical parameters...

3. How to explain that the hidden disaster factors of a mine's goaf are clear?

4. It is considered clear that the relevant work has been carried out in accordance with this standard (limited by technical conditions and current means)

5. What if the complex goaf group still cannot be explained clearly even with the means used?

6. For goafs that cannot be clearly explained, they should be evaluated from the perspective of the hidden dangers caused by the goaf and whether its prevention and control measures are in place, and directly transition to governance.

Article from: Mining Engineering

Previous Page