Controlled blasting of stepped platforms using combined blasting - Black King Kong Report

Introduction

In modern engineering construction, blasting operations are an indispensable yet extremely challenging task. Whether it's mining, excavating mountains to obtain valuable mineral resources; road construction, opening up new channels to connect different regions; or water conservancy and hydropower projects, constructing dams, dredging rivers, etc., all rely on the support of blasting technology. However, blasting operations involve the release of enormous energy. If not properly controlled, it can not only cause serious damage to the surrounding environment, such as triggering landslides and damaging the stability of surrounding buildings, but also endanger human life and cause irreparable losses. Therefore, how to maximize the blasting effect while minimizing its negative impact has become a key issue in the field of blasting engineering.

The "Pre-delay - Light" controlled blasting method has emerged as a solution, acting like a precise scalpel, providing an effective way to solve the problems in blasting operations. In actual production, this controlled blasting method can finely adjust the energy distribution and range of blasting, avoiding or reducing the harm of bench blasting or parallel blasting to the final side wall stability. It's like a skilled craftsman, carefully carving every aspect of the blasting process to ensure the safety and stability of the project.

"Pre-delay - Light" Controlled Blasting Method Analysis

Pre-splitting Blasting

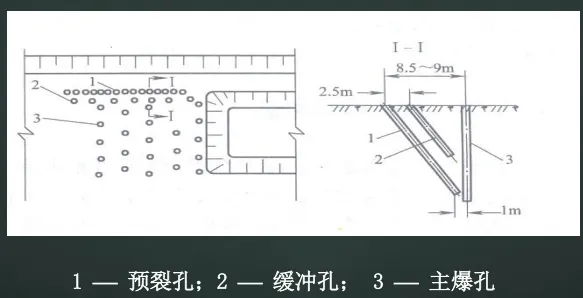

Pre-splitting blasting is the pioneer in this controlled blasting system. At the location where the bench is to form a fixed side wall bench top line, workers drill inclined boreholes. The inclination angle of these boreholes is precisely set to the inclination angle of the final side wall bench, like laying precise foundation piles for a building to be constructed. In terms of parameter setting, a down-the-hole drill with a diameter of 90-200mm is usually used for drilling, with a hole spacing S=(8-12)d. This spacing ensures effective transmission of explosive energy while avoiding excessive energy concentration causing excessive damage to the surrounding rock mass. The linear charge density is controlled by the decoupling coefficient K, where K takes (1/5-1/2). This ingenious control method is like adjusting the water flow of a faucet, ensuring that the energy of the explosive can act on the rock mass just right.

Its charging structure uses segmented decoupled charging. This structure is like setting a buffer pad between the explosive and the borehole wall, which can effectively reduce the initial pressure of the detonation wave, protect the borehole wall, prevent excessive crushing of the surrounding rocks, and keep the rock mass relatively stable during blasting. In terms of detonation sequence, the pre-splitting boreholes are detonated simultaneously before the main boreholes, creating a pre-split crack of a certain width in the rock mass. This pre-split crack acts like a strong barrier, stopping crack propagation and weakening the impact and damage of blasting seismic waves on the final side wall, providing stable boundary conditions for subsequent blasting operations.

The essence of pre-splitting blasting is to carefully control the pressure of the explosive gas products acting on the borehole wall, so that it does not exceed the dynamic compressive strength of the borehole rock, like gently stroking the rock instead of violently impacting it. In terms of quality requirements, the pre-split crack needs to have sufficient width, no less than 1-2cm, which is the key to ensuring that it can effectively block the propagation of stress waves; the pre-split surface should be relatively flat, generally its unevenness should be between ±15-20cm, which not only concerns the aesthetics of blasting but also affects the stability of the side wall; in terms of half-wall porosity, the rock mass near the pre-splitting boreholes should not have serious blasting cracks. The best blasting effect should be to leave half a borehole on the pre-splitting borehole wall, which is an important indicator of the success of pre-splitting blasting.

Buffer Blasting

Buffer boreholes are located between pre-splitting boreholes and main production boreholes. They act like a coordinator, playing a transitional and buffering role between the two. Their characteristics are distinct: the grid parameters are slightly smaller than those of the production boreholes, and the bottom of the boreholes is not over-drilled or the amount of over-drilling is reduced. This is like in a sprint race, the starting distance and sprint strength of the buffer boreholes are relatively small to avoid excessive impact on the surrounding rock mass. At the same time, controlling the amount of explosives in the buffer boreholes to be lower than that in the production boreholes further reduces the intensity of explosive energy release.

In order to prevent the explosives in the boreholes from being excessively concentrated, a segmented charging structure with filling materials or air gaps is used in the boreholes. This structure is like dividing a whole stream of water into multiple small streams, allowing the energy of the explosives to act on the rock mass evenly. When transitioning from bench blasting or parallel blasting to fixed side wall benches, allowing buffer blasting and pre-splitting blasting to proceed simultaneously, or slightly later than pre-splitting blasting, can greatly reduce the intensity of blasting vibrations, like adding a shock absorber to the violent vibrations, ensuring that the stability of the final side wall is not excessively disturbed.

Smooth Blasting

Smooth blasting is to drill a row of relatively dense boreholes on the edge line or boundary line of the pre-blasting area, or on the boundary lines on both sides of the access trench. These boreholes are like closely arranged soldiers, guarding the boundary of the blasting area. To achieve the effect of smooth blasting, the hole spacing of the smooth boreholes should be less than their resistance line, taking (0.8-1)B. This setting of the relationship between hole spacing and resistance line allows the blasted rocks to form a fracture zone along the center line of the boreholes, thus obtaining a relatively flat fracture surface.

The decoupling coefficient of the charge is slightly smaller than that of pre-splitting blasting, and the linear charge density is slightly larger than that of pre-splitting blasting. This is a fine adjustment based on the characteristics and requirements of smooth blasting to ensure that the energy of the explosives can ensure rock fracture while making the fracture surface smoother. Generally, smooth boreholes are detonated again after the main boreholes are blasted or after the debris is cleared. This arrangement of detonation time can avoid excessive interference from the main boreholes on the smooth boreholes, ensuring the effect of smooth blasting.

Comparative Analysis

Although pre-splitting blasting and smooth blasting are both important technical means in the field of controlled blasting, there are significant differences between them in several key aspects.

From the detonation sequence, pre-splitting blasting is like the vanguard, with pre-splitting holes detonated first, opening a pre-split crack in the rock mass, laying the foundation for the subsequent blasting of the main blasting area and creating stable boundary conditions; while smooth blasting is the main blasting area first blasting, after the main blasting area completes the crushing of most of the rock mass, the smooth blasting holes are then blasted. At this time, the smooth blasting holes mainly act on the edge of the blasting area, finely processing the edge rocks to obtain a flat fracture surface.

In terms of the number of free faces, pre-splitting blasting, because the rock mass is basically in a complete state before blasting and only has one free face, requires effective control of the rock mass through clever charge and initiation design under limited free face conditions; smooth blasting has two free faces, and compared to pre-splitting blasting, the rock breakage and movement during blasting have more space and directional choices, which also gives smooth blasting a certain advantage in controlling the flatness of the fracture surface.

In terms of unit explosive consumption (linear charge density), pre-splitting blasting has a relatively large explosive consumption per unit because the charge is subjected to greater constraints, and in the case of only one free face, in order to form an effective pre-split crack; smooth blasting has a small unit explosive consumption, and with two free faces, it can use explosive energy more efficiently, ensuring rock breakage while reducing explosive usage, reducing costs and reducing excessive damage to surrounding rock masses.

These differences determine their application choices in different engineering scenarios. Pre-splitting blasting is more suitable for projects with extremely high requirements for side slope stability and the need to build a stable boundary in advance; smooth blasting plays an important role when the flatness of the edge of the blasting area is high.

Actual Application Case Demonstration

In a large open-pit mining project, the "pre-buffer-smooth" controlled blasting method was successfully applied. The geological conditions of this mine are complex, with high rock hardness and well-developed joints and fissures. During mining, the stability of the side slopes faces a severe challenge. If traditional blasting methods are used, it is likely to cause geological disasters such as side slope landslides, which will not only affect the normal production of the mine but also threaten the surrounding environment and personnel safety.

In the supporting and merging stage blasting operations of this mine, pre-splitting blasting played a key role. According to the design requirements, the staff accurately drilled inclined boreholes at the position where the fixed side slope bench top line is to be formed on the supporting bench. The inclination of these boreholes is strictly controlled to be the inclination of the final side slope bench, ensuring the accurate formation of the pre-split surface. In the charging and initiation stages, a 150mm diameter down-the-hole drill was used for drilling, the hole spacing was set to 1.5m, and the linear charge density was controlled by the decoupling coefficient 3.5. A segmented decoupled charging structure was adopted, and the explosives in the hole were evenly distributed in different positions, effectively reducing the initial pressure of the detonation wave and protecting the borehole wall. The pre-splitting boreholes were detonated once before the main blast holes, successfully forming a 1.5cm wide pre-split crack in the rock mass. This pre-split crack, like a strong line of defense, effectively stopped the expansion of cracks and greatly reduced the impact and damage of the seismic waves on the final side slope during the subsequent main blast hole blasting.

Based on pre-splitting blasting, buffer blasting further ensured the stability of the side slopes. The buffer holes are located between the pre-splitting holes and the main production blast holes. Their hole network parameters are slightly smaller than those of the production blast holes, the bottom of the holes is not over-drilled, and the amount of explosives is also controlled at a low level. A segmented charging structure with air gaps was used, so that the explosive energy acted on the rock mass more evenly. In a single blasting operation, the amount of explosives in the buffer holes was reduced by 30% compared to the production blast holes, and the detonation time was slightly later than the pre-splitting blasting. Through this control, the blasting vibration intensity was significantly reduced. According to monitoring, the blasting vibration velocity was reduced by 40% compared to when buffer blasting was not used, effectively avoiding excessive disturbance to the side slope rock mass.

Smooth blasting brought high-quality blasting results to the mine's blasting operations. On the boundary lines on both sides of the entry and exit ditches, the staff drilled a row of dense smooth holes, with a hole spacing of 0.9 times the resistance line, and the decoupling coefficient of the charge was slightly smaller than that of the pre-splitting blasting, and the linear charge density was slightly larger. After the main blast holes were blasted, the smooth blast holes were detonated once, successfully obtaining a flat fracture surface, with unevenness controlled within ±10cm, and a half-wall hole rate of more than 80%. This not only improved the quality of the blasting operation but also provided good conditions for subsequent engineering construction, reducing the amount of side slope finishing work and saving time and cost.

Through the comprehensive application of the "pre-buffer-smooth" controlled blasting method, the mine successfully ensured the stability of the side slopes during mining and achieved safe and efficient production. Compared with traditional blasting methods, the mining efficiency of the mine increased by 30%, and the occurrence rate of geological disasters such as side slope landslides decreased by 80%. This case fully demonstrates the significant advantages and important value of the "pre-buffer-smooth" controlled blasting method in actual engineering and provides valuable experience and reference for blasting operations in other similar mines.