Comparison of uphill and downhill mining - Black King Kong Report

I. Introduction

In the field of mining engineering, the choice of mining method is like the cornerstone of a building, a key prerequisite for the smooth development of the entire mining operation. It has a profound impact on the mine's production efficiency, economic benefits, safety, and sustainable use of resources. Different mining methods adapt to different geological conditions, ore body occurrence states, and mining technology requirements. Once a wrong choice is made, it may lead to a series of thorny problems such as resource waste, cost increases, and frequent safety accidents.

Uphill mining and downhill mining, as two widely used mining methods in mining operations, have significant differences in many aspects, each with its unique advantages and limitations. In actual mining projects, it is an important task for mining engineers to thoroughly explore the characteristics of these two mining methods and make scientific and reasonable choices based on specific mining conditions. This is not only related to the current operating efficiency of mining enterprises but also plays a decisive role in their long-term development. Therefore, in-depth analysis and comparison of uphill and downhill mining have extremely high theoretical and practical significance, and can provide strong support for the efficient and safe development of mining engineering.

II. Advantages of Uphill Mining

(A) Transportation and Hoisting

In uphill mining, coal is transported downwards using gravity, which brings many conveniences to transportation operations. On the one hand, the operational stability of transportation equipment is greatly improved. With the assistance of gravity, the coal transportation process is smoother, reducing the risk of equipment failure due to factors such as changes in transportation resistance, reducing equipment wear and tear, thus extending the service life of the equipment, and reducing the frequency and cost of equipment maintenance and replacement. On the other hand, transportation efficiency is significantly improved. The conveyor belt can be longer, adapting to the needs of larger-scale coal transportation. When the coal seam dip angle is large, self-sliding transportation can also be used, with coal rapidly sliding down along specific chutes or roadways relying on its own gravity, greatly increasing the transportation speed, reducing transportation time, reducing transportation costs, and making the coal transportation link of the entire mining operation more efficient.

(B) Drainage System

In terms of drainage systems, uphill mining has significant advantages. Underground water can flow directly into the sump at the bottom of the shaft under the action of gravity, making the drainage path simple and clear. Unlike downhill mining, it does not require the setting up of complex drainage facilities in each mining area. The simple drainage system not only reduces construction costs and reduces the amount of excavation and construction work for drainage chambers and sumps, but also reduces the investment in drainage equipment. At the same time, maintenance and management are more convenient, reducing the risk of production interruptions due to drainage system failures, and improving the continuity and stability of mining operations.

(C) Excavation and Construction

Uphill excavation and construction have obvious advantages over downhill excavation. In the uphill excavation process, loading and transportation procedures are relatively simple. Coal and gangue can be transported downwards using gravity, reducing the difficulty and workload of upward hoisting and improving transportation efficiency. Drainage problems are also easier to solve, without facing the problem of water accumulation in the roadway affecting construction safety and progress, as in downhill excavation. This makes uphill excavation faster, allowing for the development of roadways in a shorter time, improving the efficiency of the preliminary preparation of mining operations. Improved construction efficiency means lower costs, reducing the input of labor, equipment, and other resources, and gaining more time and resources for subsequent mining operations.

(D) Ventilation System

The ventilation system of uphill mining is more reasonable. Fresh air flows into the mining area from the intake uphill, and the dirty air after cleaning the working face flows into the return airway through the return air uphill. Both fresh air and dirty air flow upwards. This ventilation method makes the air path along the dip direction shorter and the ventilation resistance smaller. The shorter air path reduces the energy loss of the airflow during transportation, allowing the ventilation fan to more efficiently deliver fresh air to each working face. Small ventilation resistance means lower energy consumption of ventilation equipment and reduced operating costs. Moreover, the shorter air path is also conducive to the rapid discharge of dirty air, ensuring the air quality of the underground working environment, providing miners with safer and more comfortable working conditions, reducing safety hazards such as gas accumulation caused by poor ventilation, and improving the safety of mining operations.

III. Characteristics of Downhill Mining

(A) Transportation Challenges

In downhill mining, the direction of coal transportation is upwards, which is opposite to the direction of gravity, posing great challenges to transportation and hoisting work. On the one hand, transportation equipment needs to overcome the gravity of coal for hoisting, which puts higher demands on the power and performance of the equipment. It is necessary to select equipment with higher power and stronger hoisting capacity, such as winches and conveyors, increasing the purchase cost and operating energy consumption of the equipment. Moreover, during upward transportation, the friction between coal and transportation equipment increases, equipment wear and tear intensifies, and the frequency of maintenance and replacement of parts increases, further increasing transportation costs. On the other hand, transportation safety risks increase significantly. During upward transportation, if equipment malfunctions, such as winch brake failure or conveyor belt breakage, coal may fall, causing serious safety accidents and causing great threats to personnel and equipment. Moreover, since the transportation direction is opposite to gravity, once an accident occurs, the difficulty of rescue and cleanup work will also greatly increase.

(B) Drainage Engineering

The drainage system of downhill mining is more complex and costly. In downhill mining, the water in the mining area needs to be discharged upwards, which requires the setting up of special drainage facilities in each mining area or even each section. A large number of drainage chambers and sumps need to be excavated for the installation of drainage equipment and the storage of water. Since the water needs to be lifted upwards for discharge, the drainage equipment needs to have sufficient lift and flow rate, which increases the difficulty of equipment selection and purchase cost. Moreover, drainage equipment needs to run continuously, consuming huge energy, further increasing drainage costs. In addition, the maintenance and management of the drainage system is also more complex, requiring regular inspection, maintenance, and maintenance of drainage equipment to ensure its normal operation. Once the drainage system malfunctions, water will accumulate, flooding roadways and working faces, affecting production safety.

(C) Excavation and Ventilation

Downslope mining presents significant challenges. Loading and transportation processes are relatively complex during downslope mining. Coal and gangue need to be transported upwards, increasing transportation difficulty, workload, and reducing efficiency. Because water in the roadway flows downwards during downslope mining, it easily accumulates at the working face, affecting construction safety and progress. To remove the water, specialized drainage facilities need to be installed in the roadway, increasing complexity and cost. Ventilation also presents difficulties in downslope mining. Fresh air flows from the intake downslope into the mining area, and the foul air after cleaning the working face flows into the return airway via the return downslope. The flow directions of fresh and foul air are opposite. This results in a longer airflow path along the dip, increasing ventilation resistance and reducing efficiency. Furthermore, the pressure difference between the intake and return downslopes is large, easily leading to air leakage and poor ventilation. To ensure effective ventilation, the power and number of ventilation equipment need to be increased, or other ventilation measures, such as installing ventilation structures, need to be adopted, increasing the construction and operating costs of the ventilation system.

IV. Economic and Technological Trade-offs

(A) Development Engineering and Cost Comparison

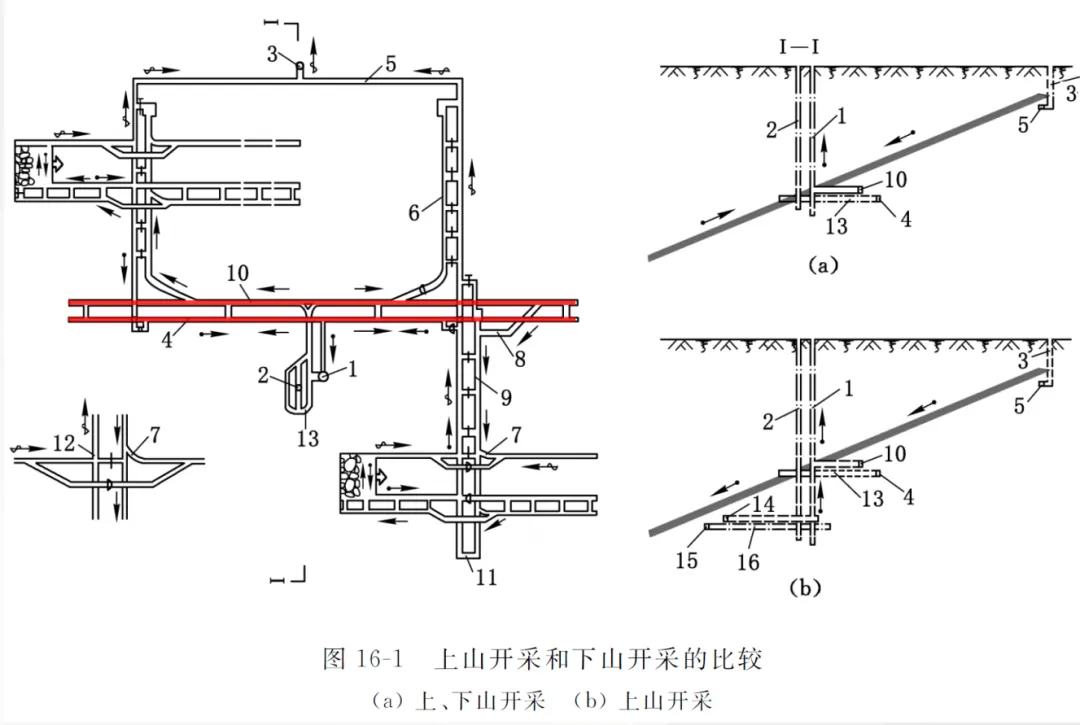

From the perspective of development engineering and construction costs, downslope mining has certain advantages. When the stage height is fixed, using upslope and downslope mining requires fewer levels than using only upslope mining. This means that the amount of engineering for the bottom roadway, chambers, etc., and the related equipment are reduced, thereby reducing basic construction investment. Reducing one mining level reduces the construction scale of the corresponding bottom roadway, including roadway excavation and equipment installation. The number and scale of chambers such as water tanks and substations will also be reduced, lowering construction costs and equipment procurement costs. Moreover, since the number of levels is reduced, the service life of each level increases, which is conducive to balanced mine production and reduces production fluctuations and additional costs caused by frequent changes in mining levels. However, upslope mining has relatively lower subsequent production and operation costs. Although upslope mining may involve return transportation in the transportation and hoisting link, resulting in slightly higher total transportation and hoisting costs than downslope mining, its cost advantages in drainage, ventilation, and excavation are obvious. A simple drainage system reduces the procurement, operation, and maintenance costs of drainage equipment. Shorter ventilation air routes reduce the energy consumption and maintenance costs of ventilation equipment. Fast excavation construction improves construction efficiency, reduces labor and equipment input, and lowers excavation costs. Therefore, when considering development engineering and costs, it is necessary to comprehensively consider the mine's construction cycle, operating costs, and long-term development plans.

(B) Analysis of Applicable Conditions

Depending on different geological conditions and coal seam occurrence states, upslope and downslope mining have their own applicable scenarios. For gently inclined coal seams with a dip angle of less than 16° and relatively small gas and water outbursts, the disadvantages of downslope mining are not serious, while its advantages in saving engineering and construction investment are more prominent. In this case, single-level upslope and downslope development or multi-level upslope and downslope development can be adopted. If the dip length of the coalfield is not large, single-level upslope and downslope development can fully utilize the existing roadway facilities of the original mining level, reducing the amount of development engineering and investment. When the dip length of the coalfield is large, multi-level upslope and downslope development can better adapt to the occurrence conditions of the coal seam, reasonably divide the mining area, and improve mining efficiency. When the deep part of the coalfield is limited by natural conditions, the reserves are not large, the deep boundary is inconsistent, and it is difficult or uneconomical to set up mining levels, a downslope mining area can be set below the final level. If the deep boundary of the coalfield is divided by an inclined fault, upslope mining may require complex engineering modifications and additional development work, which is costly and difficult. In this case, downslope mining can avoid these problems and mine deep coal resources more economically and rationally. For some multi-level mines, due to high mining intensity, short coalfield strike length, tight level succession, and the original production level not being able to guarantee the mine's output, one or several downslope mining areas can be arranged in the central part of the coalfield to arrange part of the production tasks. This can alleviate the pressure of level succession, fully utilize existing roadway facilities, and improve the overall production capacity of the mine. However, for coal seams with a larger dip angle, higher gas content, or larger water inflow, the advantages of upslope mining in transportation, drainage, and ventilation are more obvious, and upslope mining is more suitable. In high-gas mines, the shorter ventilation air route of upslope mining is conducive to quickly discharging gas, reducing the risk of gas accumulation, and ensuring safe production. When the water inflow is large, the simple drainage system of upslope mining can more effectively cope with underground water inflow and ensure the normal production of the mine. Therefore, when choosing a mining method, a comprehensive and detailed analysis and evaluation of geological conditions, coal seam occurrence state, gas and water outburst amounts, etc., must be carried out to determine the most suitable mining method.

V. Summary

Upslope and downslope mining, as two important mining methods in mining engineering, each has unique characteristics and applicable conditions. Upslope mining demonstrates significant technical advantages in transportation, drainage, excavation, and ventilation, enabling efficient and safe mining operations. However, under certain specific geological conditions and mining requirements, the advantages of downslope mining cannot be ignored. For example, in gently inclined coal seams, when deep coalfield conditions are limited, or when mine mining planning has special requirements, downslope mining can save development engineering and construction investment and extend the service life of the level.

Previous Page