Return air roadway layout of coal seam - Black King Kong broadcast

Preface

In mining engineering, the layout of return air roadways is a crucial aspect. Like the human respiratory system, it plays a key role in the entire mine's ventilation system. A rational return air roadway layout ensures smooth underground ventilation, providing workers with sufficient fresh air while promptly removing harmful gases and dust, thus ensuring a safe production environment. It is also closely related to mine production efficiency, cost control, and subsequent mining planning. An unsuitable layout may lead to increased ventilation resistance, higher ventilation costs, and even affect the normal production order of the mine. Next, we will delve into the various layouts and characteristics of return air roadways under different geological conditions and mining requirements.

Common Return Air Roadway Layout Types

Panel Ventilation or Multi-Shaft Zonal Development

In some mines, panel ventilation or multi-shaft zonal development is adopted, without a mine-wide main return air roadway. In this layout type, each panel or zone has its own independent return air system, with the airflow directly discharged to the surface from the panel or zone via the return air shaft. This is suitable for mines with large mining areas, scattered coal seam distribution, or complex geological conditions. Taking a large mining area as an example, its coal seams are distributed in multiple areas, and the geological conditions vary greatly among these areas. Using this layout, each panel can optimize its ventilation system according to its own characteristics, effectively reducing ventilation resistance, improving ventilation efficiency, and reducing the risk of the entire mine ventilation system failing due to a main return air roadway malfunction.

Layout for Near-Horizontal Coal Seams

When dealing with near-horizontal coal seams, the return air roadway is usually laid out parallel to the haulage roadway, with the return air roadway at a slightly higher elevation. This is based on the natural flow characteristics of gases; hot air and harmful gases tend to move upwards, and a higher elevation helps the return air roadway better collect these gases and exhaust them from the mine. For example, in a mine with near-horizontal coal seams, the return air roadway is laid out parallel to the haulage roadway, with the return air roadway at a certain distance above the haulage roadway. In actual production, the airflow can flow smoothly from the haulage roadway to the return air roadway, achieving good ventilation and ensuring the air quality of the underground working environment.

Layout for Stage Mining Mines

For stage mining mines, it is common practice to lay out the return air roadway below the lower coal seam or the coal seam floor. When laid out below the lower coal seam, the space of the lower coal seam can be utilized, reducing the impact on the mined coal seam and facilitating integration with the mining system of the lower coal seam. When laid out on the coal seam floor, it is mainly considered that the floor strata are relatively stable, which can reduce the difficulty and cost of roadway maintenance. For example, in a stage mining mine, the return air roadway is laid out on the coal seam floor. The floor strata have high hardness, small roadway deformation, and a long maintenance cycle, greatly reducing maintenance costs and effectively avoiding interference with mining operations due to return air roadway maintenance, ensuring normal mine production.

Special Situation Layouts

Layout When Alluvium is Thick

When the overlying alluvium is thick and the protective coal pillar is large, laying the return air roadway in the waterproof coal pillar is an effective countermeasure. The waterproof coal pillar can play a role in blocking water hazards. Placing the return air roadway within it can ensure the safety and stability of the return air roadway under complex hydrogeological conditions. However, during implementation, the dimensions of the waterproof coal pillar need to be accurately calculated to ensure that it meets the waterproof requirements while providing sufficient space for the return air roadway layout. At the same time, special support and waterproof measures should be taken during roadway excavation and maintenance to prevent damage to the integrity of the waterproof coal pillar during construction and prevent water inrush accidents.

Advantages of Consistent Elevation

Maintaining a consistent elevation for the return air roadway has many advantages for excavation and maintenance. During excavation, the same elevation allows the use of the same construction equipment and processes, reducing equipment adjustments and replacements, and improving excavation efficiency. In terms of maintenance, a consistent elevation facilitates the arrangement of drainage and ventilation facilities, reducing maintenance difficulty and cost. For example, in a certain mine, the return air roadway design strictly controls the consistent elevation. During excavation, the construction team can quickly advance, and during maintenance, drainage and ventilation equipment can be efficiently inspected and repaired, greatly improving the stability and reliability of the return air roadway.

Return Air Roadway Layout During Multi-Level Simultaneous Mining

Single Layout and Utilizing Grouped and Concentrated Roadways

In the case of multi-level simultaneous mining, the return air roadway can be designed with a single layout. With a single layout, the return air roadway of each level is constructed independently without interference, allowing flexible design and adjustment according to the actual needs of each level. This method has obvious advantages when the mining conditions of each level differ greatly. For example, in a certain mine, the thickness, dip angle, and gas content of the coal seams at different levels vary. A single layout of the return air roadway can reasonably plan the cross-sectional dimensions, support form, and ventilation equipment selection for each level, ensuring the efficient and stable operation of the ventilation system.

At the same time, using the grouped and concentrated roadway of the upper coal seam as the return air roadway for the lower level is also a feasible scheme. When the distance between the upper and lower coal seams is appropriate, and the grouped and concentrated roadway of the upper coal seam meets the requirements in terms of location, support, and ventilation conditions, this method can be adopted. In specific operations, connecting roadways need to be excavated between the upper and lower coal seams to achieve airflow connection. This can reduce the amount of new roadway excavation, reducing construction costs and time. For example, in a certain mine, the grouped and concentrated roadway of the upper coal seam is located in relatively stable strata with good support. By reasonably planning the connecting roadway, it was successfully transformed into the return air roadway for the lower level, not only saving a lot of manpower, material resources, and time, but also ensuring the smooth transition of the ventilation system.

Application of Auxiliary Level Roadways

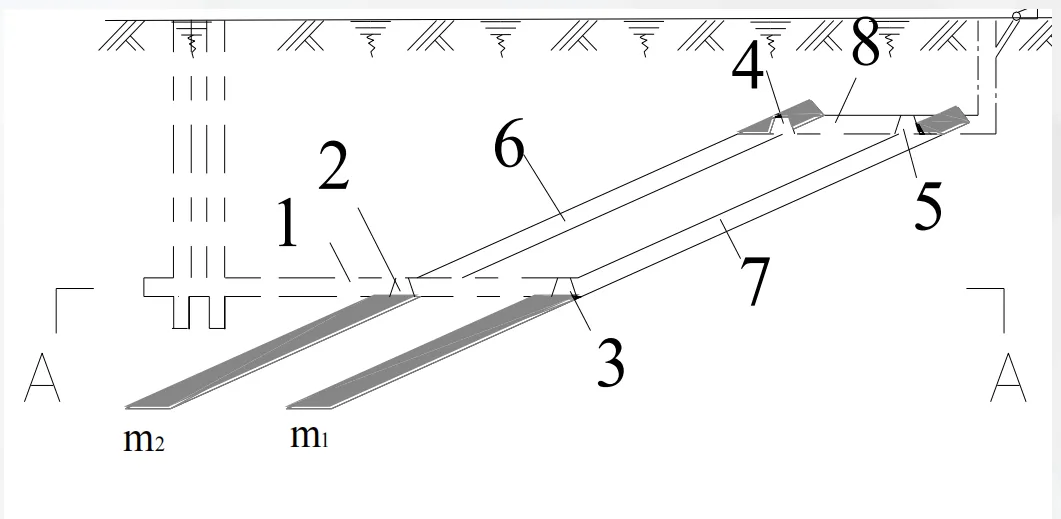

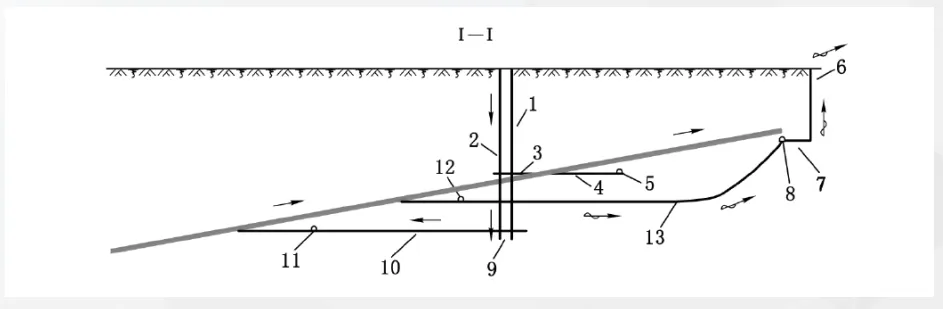

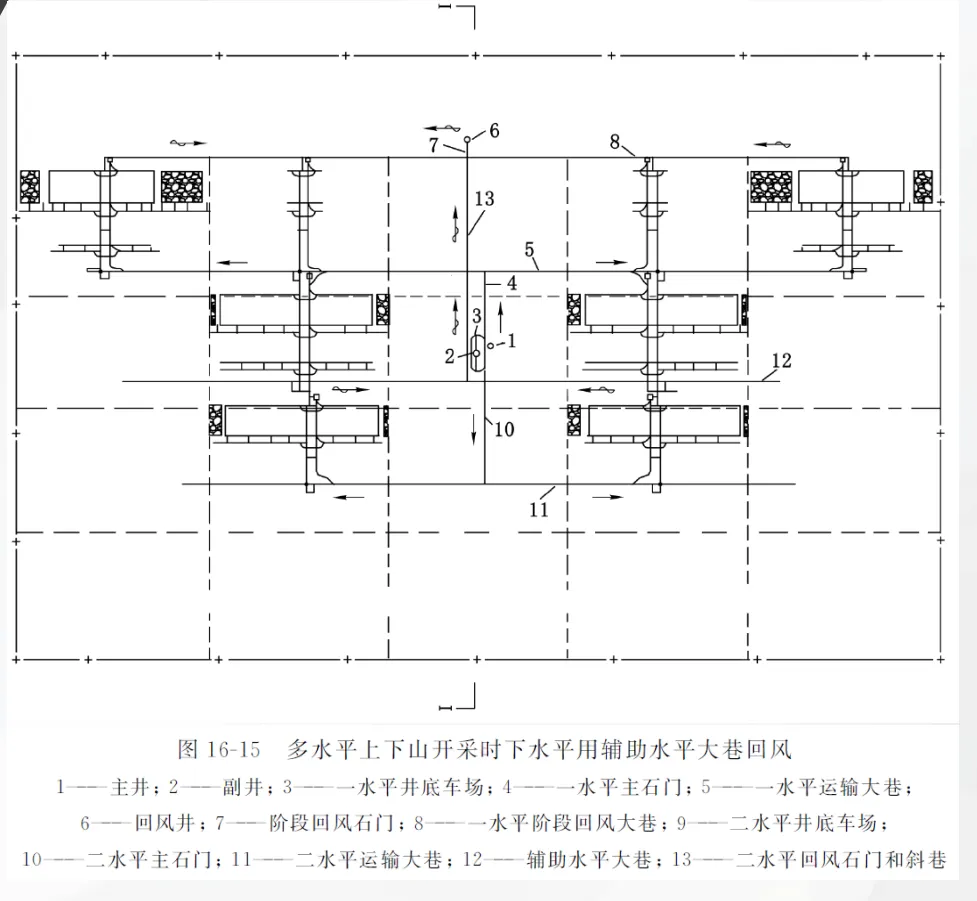

Setting the auxiliary horizontal roadway as the return airway for the lower level is a rather special but effective arrangement. In combination with the accompanying diagram (Figure 16-15: Return Airway from Auxiliary Horizontal Roadway for Lower Level in Multi-Level Up-and-Downhill Mining), in multi-level simultaneous mining, the auxiliary horizontal roadway 12 undertakes the return air task for the lower level. To achieve this function, it is necessary to excavate the No. 2 level return air stope and the inclined roadway 13, which connect to the No. 1 level return airway. The return air stope mainly plays the role of connecting different level roadways and guiding airflow. Its cross-sectional dimensions and support strength need to be designed according to the ventilation volume and geological conditions to ensure that the airflow can pass smoothly while ensuring the stability of the roadway. The inclined roadway is used to adjust the elevation and slope of the roadway so that the airflow can flow according to the designed route. In practical applications, this arrangement is suitable for mines with complex geological conditions, limited original roadway layouts, or specific mining plans. For example, in a certain mine, due to the influence of the overlying goaf and complex geological structures on the mining of deep coal seams, it is difficult to directly arrange the return airway. By setting up an auxiliary horizontal roadway and reasonably planning the return air stope and inclined roadway, the return air problem of the lower level was successfully solved, ensuring the normal production of the mine.

Summary

There are various arrangements for the return airway of the coal seam, each with its applicable conditions and unique advantages. In actual mining engineering, one cannot simply choose a certain arrangement, but needs to comprehensively consider the occurrence state of the coal seam, such as thickness, dip angle, number of layers, etc.; geological conditions, including alluvial layer thickness, rock layer stability, fault distribution, etc.; and mining technology and mine production planning and other factors.

Previous Page