Black King Kong Broadcast: Comprehensive Analysis of Ore Transportation - Introduction of Concepts and Various Transportation Methods

I. Introduction

In the complex system of mining engineering, ore transportation undoubtedly plays a crucial role, serving as the key link connecting various stages of mining operations. From the initial extraction and caving of ore to its final transportation to the concentrator or other designated locations for further processing, ore transportation is involved throughout, having a profound impact on the efficiency, cost, and safety of the entire mining operation.

In actual mining processes, ore transportation is a vital link. When ore is extracted and caved from the ore body, how to efficiently transport this ore from the working face to the transportation level becomes crucial for the smooth progress of subsequent work. Problems in the transportation link can lead to delays in the entire mining operation and significantly increased costs. For example, some mines, due to aging transportation equipment and unreasonable transportation methods, often experience ore accumulation at the working face, not only affecting subsequent mining operations but also increasing additional manpower and time costs to handle this accumulated ore.

From an economic perspective, the cost of ore transportation accounts for a considerable proportion of the mining cost, typically reaching 30% - 50%. This means that optimizing ore transportation methods and processes has enormous potential for reducing mining costs and improving economic efficiency. Taking a large mine as an example, by improving ore transportation equipment and route planning, the transportation cost was successfully reduced by 20%, significantly improving the mine's profitability. At the same time, the productivity of ore transportation directly determines the intensity of mining and the degree of concentration of mining operations. Efficient transportation enables more compact and efficient mining operations, fully utilizing the efficiency of mining equipment, thereby improving the overall production efficiency of the mine.

In addition, with increasingly stringent environmental requirements and growing safety awareness, ore transportation also faces new challenges and requirements in terms of environmental protection and safety. During transportation, how to reduce dust emissions, reduce noise pollution, and ensure the safety of ore transportation to avoid accidents have become urgent issues to be addressed. Therefore, in-depth exploration of the concept, methods, and applications of ore transportation, and continuous optimization of ore transportation technology and management, are of great practical significance for promoting the sustainable development of mining engineering.

II. Concept of Ore Transportation

Ore transportation, in short, refers to the key process of transporting the extracted and caved ore from the working face to the transportation level. This process, seemingly a simple ore displacement, actually involves many key elements and plays a crucial role in the smooth progress of the entire mining operation.

In mining operations, when ore is extracted and caved from the ore body, the curtain of ore transportation begins. This is like the baton exchange in a relay race; the caved ore is the "baton," and the transportation work is the key stage of the relay. If problems occur in this stage, the entire mining operation chain will break. For example, in a certain underground mine, due to insufficient attention to the ore transportation link, a large amount of ore accumulated at the working face, not only affecting the subsequent mining progress but also increasing additional cleaning costs.

There are clear and crucial basic requirements for the ore transportation process, namely reducing production costs and increasing productivity. These two requirements complement each other and jointly affect the economic efficiency and productivity of mining operations. From the perspective of reducing production costs, selecting appropriate transportation equipment, optimizing transportation routes, and reasonably arranging manpower can all effectively reduce cost expenditures. For example, some mines have reduced labor costs and equipment maintenance costs by using advanced automated transportation equipment to reduce manual operation steps. Increasing productivity means transporting more ore per unit of time, which requires not only efficient transportation equipment but also scientific and reasonable operational processes and management methods. Taking an open-pit mine as an example, by introducing an intelligent dispatching system to monitor and dispatch ore transportation vehicles in real time, transportation efficiency has been greatly improved, increasing the daily ore transportation volume by 30%.

It is important to emphasize that transportation work is limited to within the ore block. This definition clearly distinguishes transportation from transportation outside the mining area. The ore block is the most basic unit of underground mining. Within this specific range, ore transportation has unique operating environments and requirements. Transportation outside the mining area involves transporting ore from the ore block to the concentrator or other storage locations for long-distance transportation. Its transportation methods, equipment, and management models are different from those within the ore block. For example, transportation within the ore block may mainly use scrapers, vibrating feeders, etc., while transportation outside the mining area relies more on trucks, railways, and other transportation tools. This distinction helps mining enterprises to formulate more precise transportation strategies, improving overall operational efficiency.

III. Overview of Gravity Transportation

(1) Definition and Principle

Gravity transportation is an efficient transportation method that cleverly utilizes the self-weight sliding of ore. Its principle is rooted in the natural force of Earth's gravity. At the mining site, when ore is successfully extracted and caved from the ore body, Earth's gravity immediately takes effect, like an invisible hand, pulling the ore from high to low. This process does not require complex mechanical equipment or strong external force drive, relying only on the gravity of the ore itself to achieve displacement from the ore dropping point to the transportation roadway.

In the mining of some steeply inclined ore bodies, after the ore collapses, it slides down along the inclined surface of the mining area under the action of gravity, directly entering the ore chute at the bottom, and then being loaded into the transport mine car through the chute. This transportation method is like a natural "slide game," with the ore smoothly reaching the transportation stage along the "slide" built by gravity, greatly simplifying the transportation process and reducing energy consumption and equipment costs.

(2) Applicable Conditions

The efficient operation of gravity transportation depends on specific ore body conditions, and not all ore bodies are suitable. First, steeply inclined thin and ultra-thin ore bodies are ideal application scenarios for gravity transportation. The dip angle of these ore bodies is usually large, and the ore can quickly slide down along the steep ore body surface after caving, achieving efficient transportation. For example, in some tungsten mining, the ore body dip angle reaches more than 70°, and using gravity transportation, the ore can quickly slide from the working face to the bottom structure, greatly improving transportation efficiency.

Steeply inclined thick ore bodies or gently inclined ultra-thick ore bodies are also suitable for gravity transportation under certain conditions. For steeply inclined thick ore bodies, although the ore body thickness is large, as long as the bottom structure is reasonably designed, the ore can still be transported smoothly under the action of gravity. For gently inclined ultra-thick ore bodies, when the ore body thickness is large enough and suitable ore chutes can be excavated in the bottom rock, gravity can also be used to achieve ore sliding. In the mining of some large iron mines, by carefully designing and constructing ore chutes in the bottom rock, gravity transportation of gently inclined ultra-thick ore bodies has been successfully achieved, reducing mining costs.

In addition, when using the empty-field mining method, the ore body dip angle generally needs to be greater than 50-55°; when using the caving method, the ore can roll down along an inclined plane of 65-80° due to gravity; when the dip angle in the chute is greater than 45-60°, it is also conducive to the implementation of gravity transportation. These angle requirements are determined based on the natural angle of repose and movement characteristics of the ore. Only when these conditions are met can the ore be transported stably and efficiently under the action of gravity.

(3) Methods and Structures

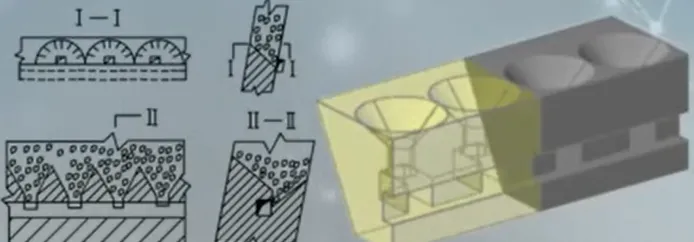

There are two main typical methods and structures for gravity transportation, each with its unique characteristics and applicable scenarios.

The first is gravity transportation without a secondary crushing roadway. This method is often used for steeply inclined thin and ultra-thin ore bodies with shallow hole ore dropping. Since there are fewer large pieces of ore produced by shallow hole ore dropping, and they can be crushed in the mining area and hopper gate, the collapsed ore can naturally slide down along the mining area and flow to the bottom structure. The bottom structure usually adopts a mining hopper gate structure, with a bottom pillar height of generally 5-8 meters, and a bin spacing of 4-6 meters to 6-8 meters. The hopper slope angle is determined according to the nature of the ore and the actual situation. The advantages of this structure are obvious: the amount of ore in the bottom pillar is small, which means less ore loss and improved resource utilization; the simple structure is easy to construct and maintain, reducing mining costs. It also has some disadvantages: the ore discharge capacity is relatively low, making it difficult to meet the needs of large-scale and high-intensity mining; the ore discharge gate requires a lot of maintenance, increasing equipment maintenance costs and downtime, affecting production efficiency. In some small mines with steeply inclined thin ore veins, due to the relatively small production demand, this gravity transportation method has been widely used.

The other is the gravity transportation structure with a grid screen chamber, mainly used for steeply inclined thick ore bodies or gently inclined ultra-thick ore bodies. Its characteristic is that the collapsed ore relies on its own weight to slide down the mining area to the ore discharge hopper, and then passes through the grid screen of the grid screen chamber. The grid screen is like an "ore filter". The ore that can pass through the grid screen will be smoothly loaded into the ore cars in the transportation roadway through the ore discharge chute and gate; while the large pieces of ore that cannot pass through the grid screen will be subjected to secondary crushing on the grid screen. Therefore, the grid screen chamber is also called the secondary crushing chamber. The height of the bottom pillar of this structure is usually 12-18 meters, and the ore volume accounts for 20%-30% of the total ore block. The setting of the grid screen position is crucial. It should generally be inclined 2-3° towards the crushing chamber, and ensure that the ore pile does not exceed 2/3 of the total area of the grid screen. This can ensure the normal operation of the grid screen and improve the ore passing rate and secondary crushing efficiency.

IV. Overview of Explosive Transportation

(1) Definition and Principle

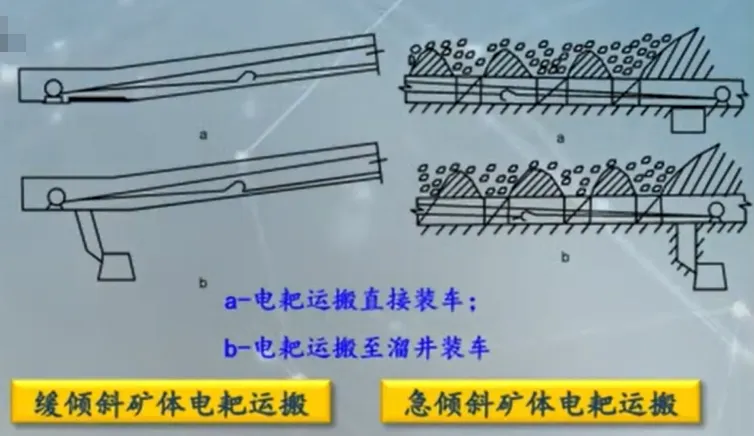

Explosive transportation is a unique ore transportation method widely used in the stoping process of inclined ore bodies. Its core principle is to appropriately increase the charge of medium-deep holes or deep holes blasting on the basis of scientific and rigorous calculations, so that the blasted ore can obtain additional kinetic energy. With this additional kinetic energy, the ore can smoothly move along the mining area floor, and can even be directly thrown from the air into the ore receiving roadway, thus efficiently completing the transportation process from the working face to the transportation level.

In actual operation, when explosives explode in the ore body, a huge amount of energy is instantly released. In addition to the energy used to crush the ore, the remaining energy gives the ore additional kinetic energy. These ore with kinetic energy, as if given the "power of flight", move or throw according to the predetermined trajectory, greatly improving the transportation efficiency. This transportation method cleverly utilizes the energy of blasting to achieve the rapid and efficient transfer of ore, bringing great convenience to mining operations.

(2) Applicable Conditions

Explosive transportation is not applicable to all ore bodies. Its effective application requires specific conditions. From the perspective of ore body dip angle, mining practice has fully shown that when the ore body dip angle is in the range of 0°-55°, explosive transportation has the possibility of implementation. Among them, when the dip angle is in the range of 30°-55°, explosive transportation can achieve more ideal technical and economic effects. At this time, under the combined action of blasting kinetic energy and its own gravity, the ore can be smoothly transported to the ore receiving roadway, realizing efficient and low-cost transportation operations. If the dip angle is less than 30°-35°, the movement of the ore on the mining area floor will become difficult, and it often needs to use equipment such as electric rakes or bulldozers to clean and transport the remaining ore on the mining area floor.

The thickness of the ore body is also a key factor affecting the applicability of explosive transportation. Generally speaking, when using explosive transportation, the ore body thickness should be 5-30 meters. This is because when the ore body thickness is in this range, the blasting wedging effect is relatively small, and the ore can obtain sufficient throwing distance and mobility under the action of blasting kinetic energy. If applied to thin ore bodies, due to the small thickness of the ore body, the blasting wedging effect will significantly increase, resulting in the ore being difficult to obtain sufficient kinetic energy, and the throwing distance will also be greatly limited, resulting in a large amount of ore loss and inability to achieve efficient transportation operations.

(3) Advantages and Disadvantages

Compared with gravity transportation, explosive transportation has significant advantages. In terms of mining preparation engineering, explosive transportation can reduce a large amount of mining preparation engineering. Gravity transportation usually requires setting up complex bottom structures and chutes, while explosive transportation can reduce the dependence on these facilities through reasonable blasting design, thereby reducing engineering construction costs and time. In terms of labor productivity and cost, explosive transportation can improve labor productivity and reduce costs. Due to the reduction of mining preparation engineering and equipment investment, and the improvement of ore transportation efficiency, more ore can be transported per unit time, thereby reducing the transportation cost per ton of ore.

Compared with mechanical transportation, the advantages of explosive transportation are also obvious. In terms of equipment requirements, explosive transportation can significantly reduce or eliminate the need for mechanical equipment. Mechanical transportation often requires a large number of electric rakes, loaders, and other equipment. These equipment not only have high purchase costs, but also high maintenance and operating costs. Explosive transportation only needs blasting operations to achieve ore transportation, greatly reducing the use of equipment. From the perspective of personnel safety, workers do not need to enter the goaf during explosive transportation, which is safer. In mechanical transportation, workers need to operate equipment in the goaf, facing safety risks such as roof collapse and ore sliding, while explosive transportation avoids these risks and ensures the safety of workers' lives.

Blasting transportation also has some undeniable drawbacks. In terms of mining pillars, blasting transportation makes it difficult to retrieve mining pillars. Due to the significant damage caused by blasting to the ore body and surrounding rock, the stability of the pillars is reduced, making it difficult to carry out safe and efficient mining operations, thus increasing the loss rate of ore. In terms of work organization, blasting transportation has a complex work organization. It requires precise blasting design, strict explosive control, and reasonable detonation sequence, etc. Any problem in any link may affect the transportation effect and safety, putting high demands on the technical level and management ability of the staff.

Blasting transportation also has the problem of high ore loss rate. During the blasting process, due to the difficulty in precisely controlling the throwing and movement of the ore, some ore is easily left in the mining area and cannot be effectively recovered, thus increasing the ore loss rate. In terms of blasting quality and explosive consumption, blasting transportation has high requirements for blasting quality and high explosive consumption. In order to ensure that the ore can obtain sufficient kinetic energy, high-quality explosives need to be used, and blasting parameters need to be strictly controlled. This not only increases the amount of explosives used and increases the cost, but may also have a certain impact on the environment. Blasting transportation also has problems such as large maintenance volume and poor ventilation conditions, which to a certain extent limit its wide application.

V. Overview of Mechanical Transportation

Mechanical transportation, as one of the important methods of ore transportation, plays an indispensable role in modern mining operations due to its high efficiency and flexibility. With the continuous advancement of mining technology and continuous innovation of equipment, mechanical transportation covers a variety of equipment and methods to adapt to different mining conditions and needs.

(1) Electric Scraper Transportation

Electric scraper transportation is a long-standing and widely used ore transportation method, with unique equipment composition and working principle. The electric scraper mainly consists of key parts such as a motor, reducer, drum, scraper bucket, and cable. The motor, as the power source, provides the energy required for the operation of the entire equipment. It transmits electrical energy to the inside of the equipment through the cable, driving the drum to rotate at high speed. During the rotation of the drum, the scraper bucket is closely connected to the drum through the steel wire rope. Driven by the drum, the steel wire rope realizes the raking and collecting action of the scraper bucket in the ore. When the scraper bucket is full of ore, the drum rotates in reverse, pulling the scraper bucket back and unloading the ore to the designated location, thus completing a transportation operation.

Electric scraper transportation has many significant advantages. In terms of equipment cost, its structure is relatively simple, and the equipment cost is low. For small and medium-sized mines with relatively limited funds, it is an economical and affordable choice. At the same time, the electric scraper is easy to move and can flexibly adjust its operating position in complex mining environments to adapt to the needs of different mining areas. It also has the characteristics of being sturdy and durable, low repair costs, and long service life, reducing the costs and time consumption caused by frequent equipment maintenance and replacement. The electric scraper transportation has a wide range of applications. Whether it is on a horizontal or slightly inclined plane, or in a gently inclined ore body with small reserves, it can play its transportation role.

Electric scraper transportation also has some obvious shortcomings. Its ore transportation work is intermittent. The process of each raking and unloading of ore by the scraper bucket is discontinuous, which to a certain extent affects the overall transportation efficiency. The steel rope is subject to great wear and tear during frequent pulling, requiring regular replacement, increasing the maintenance cost and downtime of the equipment. Moreover, electric scraper transportation consumes a lot of electricity, which is a problem that cannot be ignored for mines with high energy costs. When the raking distance increases, due to the limited traction force of the scraper bucket, the productivity will decrease sharply, making it difficult to meet the needs of large-scale, long-distance ore transportation.

Electric scraper transportation has specific applicable conditions. In terms of transportation distance, it is generally 10-60 meters. When using a small electric scraper, it can be reduced to 5-10 meters. This is because as the transportation distance increases, the efficiency of the electric scraper will decrease significantly, and the energy consumption will also increase significantly. It is suitable for operation on horizontal or slightly inclined planes. Such terrain conditions can ensure the stable operation and effective ore raking of the electric scraper. In terms of roadway height, the height of the roadway or mining area is not less than 1.5-1.8 meters to ensure that the electric scraper equipment can pass and operate normally. For gently inclined ore bodies with small reserves, less than 1.5-2 meters thick, with poor ore stability, high ground pressure, and difficult roadway maintenance, electric scraper transportation is more suitable. In the mining of some small lead-zinc mines, due to the small scale of the ore body and complex terrain conditions, electric scraper transportation can fully exert its flexible and economical advantages and effectively complete the ore transportation task.

(2) Vibrating Feeder and Conveyor Transportation

The working principle of the vibrating feeder is based on the strong vibration force generated by the vibration motor. When the vibration motor starts, it will generate high-frequency vibration, and this vibration is transmitted to the trough, so that the material in the trough is subjected to the action of the vibration force. Under the influence of the vibration force, the material overcomes its own gravity and the friction force between it and the trough, and moves forward along the inclined direction of the trough in a continuous, small throwing or sliding manner, thus realizing the conveying of the material.

The vibrating feeder has many advantages in ore transportation. It can achieve high-efficiency material conveying. Its continuous and stable vibration can ensure that the ore enters the next processing equipment uniformly, avoiding blockage and material interruption, and improving the operating efficiency of the entire production line. The vibrating feeder has excellent stability and durability. Its design uses high-strength materials and can operate stably for a long time in harsh mining environments, reducing downtime caused by equipment failures. Moreover, its structure is simple and maintenance is convenient, greatly reducing maintenance costs. In terms of energy saving and environmental protection, the vibrating feeder has significant advantages. Its low-energy consumption design not only reduces operating costs but also reduces carbon footprint. Compared with traditional conveying equipment, it produces less noise and dust during operation, which helps improve the working environment for workers and the surrounding ecological environment.

Conveyor transportation uses the continuous operation of the conveyor belt to transport ore. The conveyor belt is usually driven by a motor, and the conveyor belt moves through the rotation of the roller. The ore is placed on the conveyor belt and transported to the designated location as the conveyor belt moves. There are many types of conveyors, such as belt conveyors and chain conveyors. Belt conveyors have the characteristics of large conveying capacity, long conveying distance, and stable operation, and are suitable for large-scale, long-distance ore transportation; chain conveyors have strong load-bearing capacity and wear resistance, and are suitable for conveying blocky and granular ores.

In ore transportation, vibrating feeders and conveyors often cooperate and work together. At the mining site, the vibrating feeder evenly feeds the ore that has fallen from the mining face onto the conveyor, and the conveyor then transports the ore over long distances to the concentrator or other storage locations. In the mining of a large iron mine, the vibrating feeder evenly feeds the crushed iron ore into the belt conveyor, and the belt conveyor transports the iron ore to a concentrator several kilometers away, achieving efficient and continuous ore transportation operations.

(3) Self-propelled equipment transportation

Self-propelled equipment transportation is a highly advantageous transportation method in modern mining. It includes trackless loaders, loaders, electric shovels, and dump trucks, as well as tracked loaders and self-propelled mine cars. These pieces of equipment, with their own power systems, can move flexibly at the mining site, achieving efficient ore transportation.

Self-propelled equipment transportation has a series of outstanding characteristics and advantages. It is versatile; one piece of equipment can often complete multiple tasks. For example, a loader can both load ore and transport it over short distances, reducing the number and types of equipment and improving equipment utilization. Self-propelled equipment is mobile and flexible, able to quickly move through complex mining environments, adapting to different work locations and conditions. Their productivity is high, able to transport large amounts of ore in a short time, greatly improving the efficiency of mining operations. In terms of safety, self-propelled equipment is usually equipped with advanced safety protection devices, reducing the time operators are exposed to dangerous environments and lowering the risk of accidents.

Self-propelled equipment transportation has a certain adaptability to mining environments and operational requirements. In terms of mining methods, it is suitable for various mining methods, such as room and pillar mining, sublevel stoping, top-to-bottom layered filling, and sublevel caving. The characteristics and operational processes of these mining methods are different, but self-propelled equipment can flexibly complete ore transportation tasks according to specific circumstances. In terms of ore body conditions, it is suitable for ore bodies with stable rock and moderate dip angles. This is because self-propelled equipment requires a stable foundation and sufficient space during operation. Stable rock ensures the safe operation of the equipment, while a moderate dip angle facilitates the equipment's movement and operation. In terms of operational requirements, self-propelled equipment has high requirements for the technical level and operational standards of operators. Operators need professional training and must be proficient in equipment operation techniques and safety precautions to ensure efficient operation and operational safety.

In the mining of a large copper mine, a combination of loaders and dump trucks was used for self-propelled equipment transportation. Loaders load the fallen copper ore onto dump trucks in the mining face, and the dump trucks then transport the ore to the concentrator. This transportation method fully utilizes the advantages of self-propelled equipment, significantly increasing the daily ore transportation volume, while reducing labor costs and intensity, and improving the economic efficiency and safety of mining operations.

VI. Overview of Hydraulic Transportation

(1) Definition and Principle

Hydraulic transportation is a unique method of transporting ore along the mine floor using hydraulic power. Its core principle is to use the powerful water flow generated by a high-pressure water gun as the power source to move the ore. When a high-pressure water gun sprays a high-speed water flow, the impact force of the water flow acts on the ore, causing the ore to overcome its own weight and the friction between itself and the bottom plate, thus starting to move along the mine floor. In this process, the water flow is like an invisible hand, pushing the ore forward and achieving the transfer from the working face to the transportation level.

In the mining of some inclined or gently inclined ore bodies, the principle of hydraulic transportation is vividly demonstrated. The water flow sprayed from the high-pressure water gun, like a surging tide, rolls the fallen ore into it, causing it to flow quickly down the slope of the mine floor like a mudflow, eventually flowing into the designated ore receiving point to complete the ore transportation task.

(2) Applicable Conditions

Hydraulic transportation is not suitable for all ore bodies. Its effective implementation requires a series of specific conditions. From the perspective of ore body morphology, it is suitable for full mining or mining methods with ore left behind in inclined or gently inclined, thin or very thin ore bodies. In these ore bodies, the distribution of ore and the mining method are compatible with the characteristics of hydraulic transportation, allowing the advantages of hydraulic transportation to be fully utilized.

The condition of the mine floor is crucial to hydraulic transportation. The mine floor must be smooth and flat with few cracks to ensure that the ore can move smoothly under the push of the water flow, reducing the jamming and loss of ore during movement. If the bottom plate is uneven or has many cracks, the ore may get stuck, leading to reduced transportation efficiency or even inability to transport normally.

The nature of the ore also has an important impact on the applicability of hydraulic transportation. The ore must not be soluble in water and must not become muddy when it encounters water. This is a basic requirement. If the ore dissolves or becomes muddy in water, it will not only affect the quality of the ore but may also block the transportation channel, making transportation impossible. Low mud content in the ore is also a necessary condition, which can avoid the formation of muddy and polluted roadways, ensuring the cleanliness and smoothness of the transportation roadways, and reducing the impact on subsequent operations.

Good ore permeability is also an important condition for hydraulic transportation. In ores with good permeability, water can quickly penetrate under the action of water flow, preventing water from accumulating on the ore surface, ensuring that the ore can move stably under the push of the water flow. If the ore has poor permeability, water will accumulate on the ore surface, increasing the weight and friction of the ore and affecting transportation efficiency.

(3) Application Cases and Limitations

In mining practices at home and abroad, a few mines have applied hydraulic transportation and achieved certain results. The Smirnov mine in the Soviet Union once used hydraulic transportation, and China's Wulong Gold Mine and Duoluoshan Tungsten Mine have also used this method. In the mining of the Wulong Gold Mine, by rationally utilizing hydraulic transportation, ore or ore powder remaining on the bottom plate after gravity transportation, mechanical transportation, or blasting transportation was successfully recovered, improving the resource recovery rate.

Due to the harsh application conditions of hydraulic transportation, relatively few mines use it as the main transportation method. It is generally only used as an auxiliary transportation method to recover ore remaining on the bottom plate. This is because meeting the conditions of a smooth and flat mine floor and ore that is not soluble in water is often difficult in actual mining, limiting its widespread application.

From the perspective of labor productivity, hydraulic transportation uses the pressure of water guns to transport ore, and its labor productivity is relatively low. Compared with mechanical transportation methods, hydraulic transportation requires more manpower and time to complete the same transportation task, which to some extent affects the mine's production efficiency.

Equipment requirements and transportation costs are also important factors limiting hydraulic transportation. Hydraulic transportation requires a series of equipment such as high-pressure water guns, high-level water tanks, and water pipes, and the equipment purchase and maintenance costs are high. Moreover, due to the low efficiency of hydraulic transportation, more equipment and resources need to be invested to meet the production needs of the mine, further increasing transportation costs.

Against the backdrop of the continuous development of modern mining technology, and with the continuous improvement of mechanical transportation technology, the application scope of hydraulic transportation has gradually shrunk, and there is even a trend of being gradually eliminated. Mechanical transportation, with its advantages of high efficiency, flexibility, and strong adaptability, has become the dominant method in ore transportation.

VII. Summary

Ore transportation is a crucial link in mining engineering, and its importance is self-evident. Conceptually, ore transportation is the process of transporting mined ore from the working face to the transportation level. This process has a direct and crucial impact on the cost and efficiency of mining operations. Labor and material costs account for 30%-50% of the mining cost, and the productivity of ore transportation determines the mining intensity and the degree of operation concentration.

Gravity transportation cleverly utilizes the self-weight of the ore for sliding, suitable for steeply inclined thin and ultra-thin ore bodies, and steeply inclined thick ore bodies or gently inclined ultra-thick ore bodies under specific conditions. The methods include gravity transportation structures with and without secondary crushing roadways and grizzly chambers, each with its own unique advantages, disadvantages, and applicable scenarios.

Explosive transportation uses increased blasting charge to give the ore kinetic energy for transportation, suitable for ore bodies with an inclination of 0° - 55° and a thickness of 5 - 30 meters. It has advantages in reducing mining preparation engineering, improving labor productivity, and ensuring personnel safety, but it also has disadvantages such as difficulties in mining between pillars, complex work organization, and high ore loss rate.

Mechanical transportation includes various methods such as electric scraper transportation, vibrating feeder and conveyor transportation, and self-propelled equipment transportation. Electric scraper transportation has a simple structure, low cost, and wide applicability, but it has problems such as intermittent ore transportation, high steel rope wear, high energy consumption, and decreasing productivity with distance. It is suitable for ore bodies with specific transportation distances and conditions. Vibrating feeders and conveyors work together to achieve efficient and continuous ore transportation. Self-propelled equipment transportation has the characteristics of versatility, maneuverability, high productivity, and good safety, suitable for various mining methods and ore bodies with stable rock and moderate inclination.

Hydraulic transportation uses water to transport ore along the stope floor, suitable for inclined or gently inclined, thin or ultra-thin ore bodies, and has strict requirements on the stope floor and ore properties. Although it is used in a few mines, due to its harsh application conditions, low labor productivity, high equipment requirements, and high transportation costs, it is generally only used as an auxiliary transportation method.

Previous Page