The Origin and Development of Electric Rake Transportation - Black King Kong Report

Origin and Development of Scraper Conveyors

In 1893, scrapers first entered the mining field. For a considerable period, both domestically and internationally, they saw widespread use. In China, scrapers became one of the most widely used mining equipment, appearing in numerous mines and playing a significant role in ore extraction and transportation.

By the 1960s, the T4G scraper appeared. In the 1970s, new equipment such as loaders, vibratory feeders, and chute feeders emerged, gradually replacing some scraper functions. However, scrapers, due to their unique advantages, remain widely used in small and medium-sized mines in China. In contrast, due to their lower efficiency and inability to meet the high-efficiency demands of foreign mines, scrapers have been largely replaced by high-efficiency trackless equipment abroad.

Analysis of the Characteristics of Scraper Ore Transportation

(a) Detailed Advantages

The long-standing presence of scrapers in mining is due to their numerous advantages. Structurally, scrapers are simple, offering advantages in manufacturing and maintenance. Production and assembly require no complex processes or high technical costs, making them ideal for many financially constrained small and medium-sized mines. The low equipment cost further reduces upfront investment and financial pressure.

In operation, their mobility is a significant advantage. Scrapers can be flexibly deployed in different areas based on site conditions, quickly responding to ore handling needs. They can operate in narrow tunnels or open pits, reaching designated locations easily. Furthermore, scrapers are durable and can withstand harsh mining environments. They operate reliably despite impacts from ore, dust erosion, and moisture, minimizing downtime and ensuring continuous mining operations. Low repair costs further reduce maintenance expenses and improve economic efficiency.

Additionally, scrapers are versatile, adapting to various ore body conditions and mining environments. They are effective in both gently and steeply inclined ore bodies. In low-reserve, gently inclined ore bodies less than 1.5-2m thick, with poor ore stability, high ground pressure, and difficult tunnel maintenance, scrapers demonstrate unique applicability, operating directly in the mining area and providing a reliable solution for ore transportation. The combined scraping and loading function simplifies the transportation process, improving efficiency and reducing potential problems and losses in intermediate stages.

(b) Discussion of Disadvantages

However, scrapers are not without flaws. Intermittent ore transportation is a significant issue. Scrapers constantly travel between the ore pile and loading point, resulting in discontinuous transportation. Each round trip consumes time, hindering overall efficiency and failing to meet the high-efficiency demands of some mines.

Significant wire rope wear is another major problem. The wire rope endures immense tension and frequent contact with equipment and ore, accelerating wear. Frequent replacements increase maintenance costs and disrupt mining operations, reducing productivity. High energy consumption is also a drawback. With rising energy costs, this increases operational costs and reduces profit margins.

During transportation, ore is easily crushed, negatively impacting quality and subsequent processing. Crushed ore increases beneficiation difficulty, reduces recovery rates, and affects economic efficiency. Productivity decreases sharply with increased haulage distance. Beyond a certain range, efficiency drops significantly, limiting scraper use in large-scale mines.

Understanding the Operating Conditions of Scraper Conveyors

The use of scraper conveyors has specific limitations, closely related to their operational characteristics and actual ore body conditions, critically influencing their application in mining operations.

Haulage distance has a defined range. Typically, it is 10-16m, reducing to 5-10m with small scraper winches. In practice, horizontal haulage generally does not exceed 40-50m, with the optimal distance being below 20-30m. Downward haulage on slopes less than 25°-30° does not exceed 50-60m, optimally below 30-40m. In Chinese underground mines, haulage distances are typically 30-50m. Haulage distance significantly impacts productivity, decreasing sharply with increased distance. This is because increased distance lengthens round-trip times, exacerbating intermittent operation, increasing wire rope wear, and raising energy consumption, thus reducing overall efficiency. Therefore, haulage distance must be controlled based on ore body distribution and mining requirements to ensure efficient operation.

The working plane angle is another crucial factor. Scrapers operate on level and slightly inclined planes, and can also scrape downwards along a 25°-30° inclined floor or upwards along a 10°-15° incline. Efficiency and difficulty vary with the angle. Downward scraping utilizes gravity, potentially increasing efficiency, but speed must be controlled to prevent accidents. Upward scraping requires more power and stronger wire rope, increasing difficulty and reducing efficiency. Therefore, precise measurement and analysis of the ore body angle are necessary to select the most suitable scraping method.

The height of the haulage roadway is equally important and should not be less than 1.5-1.8m. This height requirement is to ensure that the electric scraper can operate normally in the roadway, avoiding failure to pass through due to insufficient roadway height, or collisions with the top of the roadway during operation, damaging equipment and affecting the normal progress of mining operations. At the same time, a suitable roadway height is also conducive to ventilation and personnel passage, ensuring the safety and efficiency of mining operations.

For gently inclined ore bodies with small reserves, when the thickness is less than 1.5-2m, and the ore is unstable, the ground pressure is high, and roadway maintenance is difficult, the method of electric scraper ore transportation is more suitable, and it can even directly enter the mining area. Under such ore body conditions, some other large and complex transportation equipment may not be able to operate effectively due to the instability of the ore body and the difficulty of roadway maintenance, while the electric scraper, due to its simple structure, convenient movement, and wide range of applications, can adapt well to this complex environment and provide reliable guarantee for ore transportation.

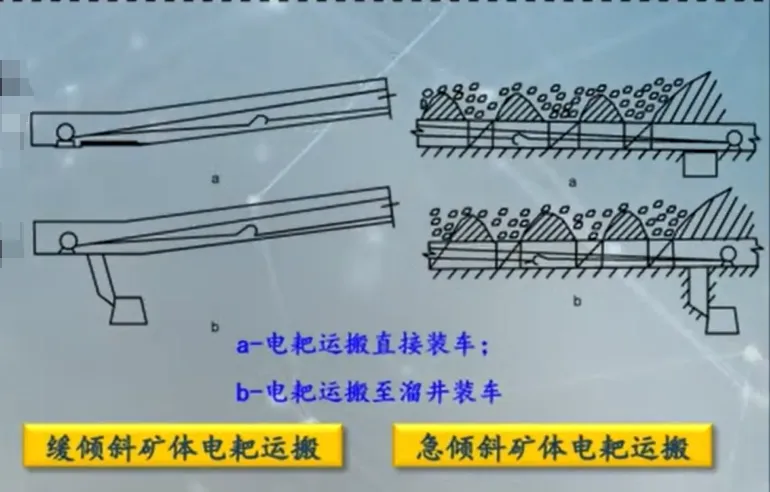

Diverse presentations of open-pit scraping methods

(1) Scraping along the bottom plate of gently inclined ore bodies

In mining operations, for gently inclined ore bodies, scraping along the bottom plate is a common and important open-pit scraping method. When facing gently inclined ore bodies, during the process of scraping ore in the open pit, the method of scraping along the bottom plate of the open pit is mostly adopted. The operation process of this method is relatively direct. The collapsed ore naturally slides down to the bottom plate of the open pit under the action of gravity, and then the electric scraper plays a role, scraping the ore along the bottom plate to achieve direct loading, or scraping the ore to the chute. In some small-scale mining operations, the mining scene of gently inclined ore bodies is more common. After the blasting operation in the open pit, the ore collapses to the bottom plate of the open pit. At this time, the worker operating the electric scraper skillfully starts the equipment, and the scraper bucket of the electric scraper, under the traction of the steel wire rope, scrapes the ore along the bottom plate of the open pit and directly loads it into the ore car parked next to it. The whole process is completed in one go. If a chute is set up near the open pit, the electric scraper will scrape the ore to the chute for subsequent transportation and processing.

This open-pit scraping method has unique applicable scenarios and advantages. When the dip angle of the ore body is small and the ore and surrounding rock are relatively stable, scraping along the bottom plate can fully exert its efficient and convenient characteristics. Due to the gentle dip of the ore body, the ore can slide smoothly on the bottom plate, reducing the resistance and energy consumption during transportation. At the same time, the direct loading method greatly shortens the transportation path of the ore, improves transportation efficiency, and reduces the possible ore loss and equipment failure in the intermediate links. Moreover, this method has relatively low requirements for equipment and technology, and the cost is also relatively controllable. For some mining enterprises with limited funds and technical strength, it is an economical and practical choice. However, it also has certain limitations. When the dip angle of the ore body changes significantly, or the stability of the ore is poor, scraping along the bottom plate may be affected, leading to reduced transportation efficiency, or even safety hazards.

(2) Special ore scraping roadway for steeply inclined ore bodies

For steeply inclined ore bodies, setting up a special ore scraping roadway is a more suitable open-pit scraping method. In the mining of steeply inclined ore bodies, the ore flows into the specially set ore scraping roadway by its own weight, which is the key starting point of the entire operation process. Due to the steep dip of the ore body, the ore has a high sliding speed and impact force under the action of gravity, and can quickly flow into the ore scraping roadway. After entering the ore scraping roadway, the electric scraper scrapes the ore to the chute, or directly into the ore car via the loading platform. In the mining site of steeply inclined ore bodies in a large metal mine, this open-pit scraping method was adopted. During the mining process, as the mining operation progresses, the collapsed ore quickly slides down from a high place along the surface of the steeply inclined ore body and directly flows into the pre-set ore scraping roadway. In the ore scraping roadway, the electric scraper has already been in place. The operator flexibly controls the electric scraper according to the inflow of ore, scraping the ore to the chute. The ore in the chute is then transported to the designated location for further processing through the subsequent transportation system; or, the electric scraper directly scrapes the ore into the ore car on the loading platform, realizing the rapid loading and transportation of the ore.

This open-pit scraping method is of great significance and significant advantages in the mining of steeply inclined ore bodies. The special ore scraping roadway provides a relatively stable and safe channel for ore transportation, effectively guiding the flow of ore and reducing the scattering and loss of ore during transportation. By reasonably designing the location, slope, and structure of the ore scraping roadway, the self-weight of the ore can be fully utilized to improve transportation efficiency and reduce energy consumption. Moreover, concentrating the ore scraping operation in a special roadway facilitates equipment arrangement and operation, and is also conducive to equipment maintenance and management. At the same time, this method can also adapt to the complex geological conditions of steeply inclined ore bodies, and improve the mining and transportation efficiency of ore while ensuring mining safety, providing a strong guarantee for the efficient production of mines.

Correlation between electric scraper equipment parameters and productivity

(1) Introduction to electric scraper equipment parameters

Electric scraper equipment has many parameters, these parameters are interrelated, and jointly affect the working performance and efficiency of the electric scraper, playing a key role in mining operations.

The power of the electric scraper winch is one of the important parameters to measure the working capacity of the electric scraper. The power range of electric scraper winches used in China is 5.5-55kW, while those abroad are mostly 100-130kW. Winches with different power are suitable for different working scenarios. Winches with a power of 5.5-7kW are relatively small and are usually used for roadway excavation operations. In the process of roadway excavation, the amount of ore to be transported is relatively small, and the working space is relatively narrow. This low-power winch can operate flexibly in a small space to meet the needs of ore transportation during roadway excavation. Winches with a power of 14-28 (30) kW are often used in small open pits. The scale and ore output of small open pits are moderate, and winches in this power range can effectively complete the ore scraping work. Winches with a power of 28 (30)-55kW are often used in electric scraper roadways. Electric scraper roadways are key channels for ore transportation, requiring winches to have a large power to ensure that ore can be efficiently scraped from the open pit to the designated location.

The bucket capacity is also an important parameter of the electric scraper equipment, with a bucket capacity between 0.1 and 0.6 cubic meters. In practical applications, the commonly used bucket capacity is 0.2-0.3 cubic meters. Different types of buckets are suitable for different types of ores. The box-shaped bucket, with its structural characteristics, has advantages in transporting soft, fragmented ores. When facing soft, fragmented ores, the box-shaped bucket can better accommodate and grab the ore, reducing ore spillage and improving transportation efficiency. The grate bucket is suitable for transporting hard ores. Its special grate structure can effectively break and grab hard ores, meeting the needs of transporting hard ores. Foreign bucket capacities have reached 2 cubic meters. This large-capacity bucket, when facing large-scale, high-intensity mining operations, can grab more ore at a time, improving transportation efficiency, but it also requires higher equipment power and overall performance.

The pulley diameter is 20-350mm, and the electric scraper tail rope is generally suspended using a pulley. During the operation of the electric scraper, the pulley plays a role in changing the direction of the wire rope and reducing wire rope wear. A suitable pulley diameter can ensure that the wire rope remains in good condition during operation, improving the working efficiency of the electric scraper and the service life of the wire rope. The wire rope diameter is 9-19mm. As a key component connecting the bucket and the winch, the wire rope needs sufficient strength to withstand the weight of the bucket and ore and the pulling force during operation. Wire ropes of different diameters are suitable for winches of different powers and different operating conditions. Thicker wire ropes can withstand greater pulling force and are suitable for winches with higher power and operations with longer distances and heavier ores; thinner wire ropes are suitable for winches with lower power and relatively lighter operating conditions.

(II) Analysis of Factors Affecting Productivity

The productivity of electric scraper transportation is not fixed but is affected by a combination of factors that interact to determine the actual production capacity of the electric scraper in mining operations.

There is a close positive correlation between the power of the electric scraper winch and productivity. The greater the winch power, the greater the traction force it can provide, allowing the bucket to grab and transport ore more forcefully, thereby increasing the amount of ore transported per unit of time. In the mining operations of some large mines, the use of high-power electric scraper winches can quickly transport a large amount of ore from the mining area to the transportation roadway, greatly improving the efficiency of mining operations. If the winch power is insufficient, when facing larger ore or longer transportation distances, the bucket may fail to operate normally or the transportation speed may be too slow, resulting in reduced productivity.

The bucket capacity also significantly affects productivity. A larger bucket capacity can load more ore at a time, transporting a larger total amount of ore with the same number of transportations, thereby increasing productivity. In mining areas with high ore output, electric scrapers with large-capacity buckets can fully utilize their advantages, reducing the number of transportations and improving transportation efficiency. However, it should be noted that the bucket capacity is not the larger the better, and factors such as winch power and operating environment should also be considered. If the winch power cannot match the large-capacity bucket, or the operating space is narrow, the large-capacity bucket may not be able to operate normally, which will reduce productivity.

The transportation distance is one of the key factors affecting the productivity of electric scraper transportation. As the transportation distance increases, the time required for the electric scraper to make a round trip will increase, and the problem of intermittent ore transportation will become more prominent, which directly leads to a reduction in effective transportation time per unit of time and a sharp decline in productivity. The horizontal transportation distance generally does not exceed 40-50m, with the optimal distance being below 20-30m; for inclined downward transportation with an inclination angle of less than 25°-30°, the distance does not exceed 50-60m, with the optimal distance being below 30-40m. The transportation distance in underground mines in China is usually 30-50m. In actual mining operations, the transportation distance should be kept within a reasonable range to ensure the efficient operation of the electric scraper.

In addition to the above factors, ore size, the number of hopper blockages, and ore mining conditions will also affect the productivity of electric scraper transportation. Larger ore sizes may make it difficult for the bucket to grab the ore or cause blockages during transportation, affecting transportation efficiency. An increase in the number of hopper blockages will interrupt the operation of the electric scraper, requiring time for cleaning, thereby reducing productivity. Ore mining conditions, such as horizontal, uphill, or downhill, will also affect the efficiency of the electric scraper. During uphill transportation, the electric scraper needs to overcome gravity, increasing power consumption and reducing efficiency; during downhill transportation, although there is gravity assistance, it is necessary to control the speed to ensure safety and transportation efficiency.

Summary

Electric scraper transportation has occupied an important position in the history of mining. Since its inception in 1893, it has gone through a development process from widespread application to coexistence with new equipment. Its advantages are obvious: simple structure, low equipment cost, convenient movement, durability, low repair cost, and wide range of applications, making it irreplaceable in various mines, especially small and medium-sized mines. In the mining of ore bodies with small reserves and complex conditions, electric scraper transportation shows unique applicability, providing a reliable solution for ore transportation.

However, the disadvantages of electric scraper transportation cannot be ignored. Problems such as intermittent ore transportation, high wire rope wear, high power consumption, easy ore crushing, and a sharp decline in productivity with increasing transportation distance limit its application in some large-scale, high-efficiency mines. In actual use, it is crucial to strictly meet its usage conditions. Transportation distance, operating plane angle, transportation roadway height, and ore body conditions all directly affect the effectiveness of electric scraper transportation. Different mining area transportation methods, such as transportation along the bottom plate of gently inclined ore bodies and the setting of special ore mining roadways for steeply inclined ore bodies, also need to be reasonably selected according to the specific conditions of the ore body.

Electric scraper equipment parameters, such as winch power, bucket capacity, pulley diameter, and wire rope diameter, are closely related to productivity. In mining operations, these factors need to be comprehensively considered to achieve efficient operation of electric scraper transportation. With the continuous development of mining technology, although new equipment continues to emerge, electric scraper transportation, with its own advantages, will continue to play an important role under specific mine conditions.

Previous Page