Flat bottom structure in deep mining of metal mines - Black King Kong report

Preface

In the deep mining process of metal mines, the bottom structure, as a key part connecting the mining area and the transportation system, its design rationality directly affects important indicators such as mining efficiency, ore loss and impoverishment, and mining cost. The flat bottom structure, as a common form of bottom structure, has unique application value in deep mining of metal mines. Therefore, in-depth research on flat bottom structures has important practical significance for improving the overall efficiency of deep mining of metal mines.

Flat Bottom Structure

Structural Characteristics

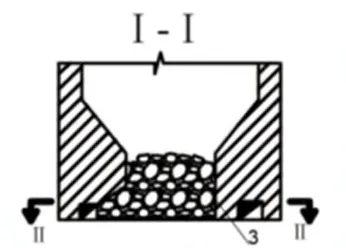

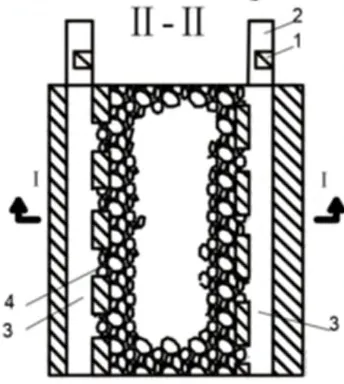

The flat bottom structure has unique layout characteristics in the deep mining of metal mines. Its pulling bottom level and electric scraper road are at the same level. This design makes the bottom structure of the mining area relatively simple. After the ore is mined, a triangular ore pile will naturally form at the pulling bottom level. As the mining progresses, the upper ore relies on its own gravity and flows smoothly into the electric scraper roadway through the ore discharge port along the slope of the triangular ore pile. The size of the ore discharge port is generally controlled at 2.5-3m, which can ensure the smooth discharge of the ore and control the ore discharge speed to prevent problems such as too fast ore discharge or blockage. When arranging the ore discharge port, it is usually set on one side of the electric scraper roadway; when the ore is extremely stable, it can also be considered to arrange the ore discharge port on both sides of the electric scraper roadway to further improve the ore output efficiency.

Significant Advantages

The advantages of the flat bottom structure are quite obvious. First, its structure is simple. Compared with some complex bottom structures, it is more convenient in design and construction, and does not require too many complex processes and technical requirements. This directly leads to a significant reduction in the amount of mining preparation engineering. According to relevant statistics, compared with some traditional bottom structures, the amount of mining preparation engineering can be reduced by about 20%-30%, which not only saves a lot of manpower, material resources, and time costs, but also speeds up the mining progress. Secondly, the cutting efficiency of the flat bottom structure is high. Its cutting process is similar to the mining operation, and it can quickly complete the cutting work of the bottom structure, leaving more time for the subsequent mining process. Furthermore, due to its structural characteristics, the ore discharge conditions are good, and the ore can flow smoothly from the ore discharge port into the electric scraper roadway, reducing blockages and other failures during the ore discharge process, and improving the ore output efficiency. Finally, the bottom pillar ore volume of this structure is small, which can effectively improve the ore recovery rate, reduce resource waste, and reduce mining costs to a certain extent.

Existing Disadvantages

Although the flat bottom structure has many advantages, there are also undeniable disadvantages. The triangular ore pile remaining in the mining area is its most prominent problem. In this stage of mining, these triangular ore piles cannot be recovered in time, and they can only be dealt with when they are mined in the next stage. This leads to large ore loss and impoverishment. On the one hand, the remaining triangular ore piles occupy a large amount of ore resources, reducing the ore recovery rate in this stage; on the other hand, when these ores are recovered in the next stage, due to long-term storage, the ores may be affected by the surrounding environment, such as being mixed with rocks, resulting in ore impoverishment, reducing the quality and value of the ore. According to actual mining experience, when using a flat bottom structure, the ore loss rate may reach 15%-25%, and the impoverishment rate may also reach 10%-15%, which has a great impact on the economic benefits of metal mine mining.

Applicable Conditions

The flat bottom structure has certain requirements for mining conditions and is most suitable for application under stable ore conditions. When the ore has good stability, it can ensure the stability of the mining area during the mining process and reduce safety accidents and mining difficulties caused by ore collapse. If a flat bottom structure is used under unstable ore conditions, problems such as roof collapse and ore discharge port blockage may occur, seriously affecting mining efficiency and safety. For example, in some mining areas where ore joints and fissures are developed and rocks are broken, if a flat bottom structure is forcibly used, top plate caving may occur frequently, which will not only threaten the life safety of operating personnel, but also cause frequent interruptions in mining work, increasing mining costs. Therefore, when choosing the form of the bottom structure, the key factor of ore stability must be fully considered.

Actual Application Cases

Tungsten Mine Application Case

The No. 5 ore body of a certain tungsten mine uses a flat trench bottom structure and shallow hole ore-leaving method for mining experiments, and has achieved good technical indicators and economic benefits. The ore body is a semi-hidden single vein-network vein blind ore body, with a strike close to EW, dipping S, dip angle 41-55°, strike length 160m, horizontal thickness 1.28-12.21m, average 7.45m, and occurrence elevation 338-558m. The ore is hard and stable, f=14, and the surrounding rocks of the top and bottom plates are both sericite-cloud mica plagioclase gneiss, hard and stable, f=10-12.

In the mining method experiment, the No. 3906 ore block of the No. 5 ore body was selected. This ore block is located in the 390 middle section between the L2 exploration line and the F28 fault. The mining area is arranged along the strike, with a length of 60m, a height of 40m in stages, a width equal to the ore vein thickness, no top and bottom pillars are left, and 3-4m pillars are left on both sides. The distance between the connecting roadways in the shaft is 4-5m, the distance between the trench ore discharge ports is 5-7m, and an exploration sub-middle section is arranged in the stage. The mining preparation engineering includes stage transportation flat roadways, exploration sub-middle sections, two-sided pedestrian ventilation shafts, shaft connecting roadways, pulling bottom roadways, electric scraper roadways, ore discharge ports, short chutes, ventilation connecting roadways, etc. The cutting uses the pulling bottom roadway as the free surface, and the gangue is expanded to form a pulling bottom space, creating conditions for shallow hole ore dropping.

By using the flat trench bottom structure and shallow hole ore-leaving method, this ore block has achieved good mining results, effectively controlling ore loss and impoverishment, and improving mining efficiency, providing valuable experience for the subsequent mining of this tungsten mine.

Hatu Gold Mine Application Case

The L27-14 vein of Hatu Gold Mine uses a flat bottom structure and shallow hole ore-leaving method, effectively solving some problems in deep mining. Previously, this ore vein used the shallow hole ore-leaving method for mining. For extremely thin ore veins (0.4-0.8m thick), a mixed mining method was adopted, resulting in a mining impoverishment rate as high as 50% or more, a high waste rock mixing rate, a serious decline in ore grade, and increased beneficiation costs. The surrounding rocks of the top plate are moderately stable, with serious foliation, and there are considerable safety hazards.

The ore body at L27 - 14 is not stable enough, the surrounding rock is moderately stable, the ore body dip angle is 60 - 67°, and the average thickness of the ore body is 0.6m, which belongs to an inclined thin ore body. Based on these mining conditions, and adhering to the principles of economic rationality and safe and efficient operation, it is chosen to adopt the flat-bottom shallow-hole mining method for testing. The mining area is arranged along the strike of the ore body, with a length of 40m, a personnel access shaft width of 1.2m, a mining area width equal to the ore body thickness, and a mining area height equal to the stage height of 40m. At the bottom of the ore body, an advance shaft is excavated every 6m, dividing the mining area into several sections. The advance shaft serves as the personnel work point, and all drilling operations are completed in the advance shaft. A connecting passage is excavated in the personnel access shaft every 5m of vertical height from bottom to top. A ventilation and personnel access shaft is set at each end of the mining area, and a hopper is set every 5m at the bottom of the mining area.

During mining, a YT - 7655 type drilling rig is used, with a hole depth of 2.5m. Holes are arranged in the ore body from bottom to top, with a hole spacing of 0.5m. Emulsified ammonium nitrate explosives are used for blasting, and plastic detonating tubes are used for detonation. The mining height for each blast is 3 - 5m. The ore flows into the bottom hopper by gravity, then is transferred to the main roadway and transported out of the mine. By adopting the flat-bottom shallow-hole mining method, the ore loss and depletion of this ore vein are improved, and mining safety is enhanced.

Xishimen Iron Mine Application Case

Xishimen Iron Mine faced many challenges during mining. As the mining depth increased, thick ore bodies became scarce, and the main ore bodies changed to gently inclined and inclined medium-thick ore bodies. The underlying skarn layer was extremely unstable, the overlying limestone was moderately stable, and the ore body was moderately stable to stable. In addition, the ore bodies in the current production section were severely damaged by small ore points, resulting in incomplete and damaged ore bodies. Currently, the sublevel stoping method is used for mining. Due to the incomplete and damaged ore bodies, the cutting engineering and blasting holes cannot be fully in place during mining, resulting in poor blasting quality. As a result, the ore in the relatively stable top part and the remaining pillars often cannot be blasted down, leading to hanging roofs and walls. In addition, in some original ore body mining areas with smaller thicknesses, the overlying rock often cannot collapse as mining progresses, causing the ore to fall into the empty area and cannot be removed, resulting in poor production reliability and significant ore loss.

To solve these problems, Xishimen Iron Mine proposed various flat-bottom bottom structure schemes for different ore body conditions. For thin ore bodies, a single trench flat-bottom mining scheme is adopted; for medium-thick ore bodies, a double trench flat-bottom mining scheme is studied, where three access roads are classified as one mining unit, and ore crosscuts are blasted from the middle access road to both sides, forming a double trench ore falling and flat-bottom mining bottom structure. During mining, the two side trenches are the same as the access roads of the sublevel stoping method, and are mined by blasting holes row by row. The ore is transported to the point where the shovel loader operator cannot enter the empty area, and the ore that falls into the empty area and the ore that falls after the hanging roof is discharged from the ore crosscut. A series trench flat-bottom mining scheme is also proposed as a supplement to the sublevel stoping method.

Through the application of these schemes, Xishimen Iron Mine effectively mined various residual ores, significantly improved mine production capacity, and significantly improved the safety conditions of the mining area. For example, in areas using the double trench flat-bottom mining scheme, the ore recovery rate increased by about 20% - 30%, and the number of production stoppages due to top collapses and other problems was significantly reduced, ensuring the continuous and stable production of the mine.

Comparison with Other Bottom Structures

In deep mining of metal mines, the selection of the bottom structure is crucial. Different bottom structures have significant differences in the amount of preparatory engineering, ore loss and depletion, and applicable conditions. Common comparison objects for flat-bottom structures include hopper-type bottom structures and trench-type bottom structures.

Comparison with Hopper-Type Bottom Structures

The hopper-type bottom structure is a more traditional bottom structure form, with a hopper-shaped ore receiving roadway at the bottom of the mining area. In terms of preparatory engineering, the hopper-type bottom structure is relatively large, requiring the excavation of numerous hopper necks and ore passes. Taking a small mine as an example, when using a hopper-type bottom structure, the preparatory ratio per thousand tons of ore reaches 20 - 30m, while the preparatory ratio of a flat-bottom structure is usually 10 - 15m, a significant difference. The ore loss and depletion of the hopper-type bottom structure is also more prominent. Due to the residual ore in the ridge between the hoppers, and the tendency for ore to block the hopper neck during ore discharge, the ore loss rate can reach 15% - 25%, and the depletion rate can reach 10% - 15%. In comparison, although the flat-bottom structure also has the problem of residual triangular ore piles, it has different performances in some aspects of ore loss and depletion. The hopper-type bottom structure is suitable for various ore conditions and is widely used, but when the ore is less stable, the maintenance cost of the hopper is higher; while the flat-bottom structure focuses more on stable ore conditions.

Comparison with Trench-Type Bottom Structures

The trench-type bottom structure has a V-shaped trench ore receiving trough. Compared with the flat-bottom structure, the amount of preparatory engineering is also larger. The excavation of the trench requires certain technical and equipment support, and the layout of the ore discharge roadway is also more complex. When a large metal mine uses a trench-type bottom structure, the construction period of its preparatory engineering is about 20% - 30% longer than that of a flat-bottom structure. In terms of ore loss and depletion, the trench-type bottom structure has a certain advantage over the flat-bottom structure. Its ore receiving range is large, the ore flow is smoother, the ore loss rate is generally 10% - 15%, and the depletion rate is 5% - 10%. This is because its V-shaped trench can effectively guide the ore flow and reduce ore residue. However, the trench-type bottom structure has higher requirements for the stability of the ore and rock. When the ore and rock are unstable, trench collapses and other problems are likely to occur, affecting mining safety and efficiency. The flat-bottom structure has relatively lower requirements in this aspect, as long as the ore is stable.

Summary

In the field of deep mining of metal mines, flat-bottom structures, with their simple structure, small amount of preparatory engineering, high cutting efficiency, and suitability for efficient ore discharge equipment, demonstrate unique application value under mining conditions where both ore and surrounding rock are stable. Practical application cases from a tungsten mine, the Hatu gold mine, and Xishimen Iron Mine show that the rational use of flat-bottom structures can effectively improve mining efficiency and control ore loss and depletion to a certain extent. However, its shortcomings cannot be ignored, such as the large ore loss and depletion caused by the residual triangular ore piles in the mining area, which limits its wider application to some extent.

Compared with funnel-shaped and trench-shaped bottom structures, flat-bottom structures have their own advantages and disadvantages in terms of mining engineering quantity, ore loss and impoverishment, and applicable conditions.