Understanding Gravity Conveying in One Article - Black King Kong Broadcast

Preface

Ore transportation, as a crucial part of mining operations, refers to the process of transporting collapsed ore from the working face to the transportation level. This process plays a pivotal role in the extraction work of various mining methods, with labor and material costs accounting for approximately 30%-50% of the extraction costs. The productivity of ore transportation directly determines the intensity of extraction and the concentration of extraction operations. In mining practice, there are often situations where a large amount of ore is efficiently mined, but the transportation efficiency is low, which not only affects the overall mining progress but may also lead to the accumulation and waste of resources. Therefore, the requirement for the ore transportation process is to achieve low cost and high productivity to ensure the efficient and economical development of mining operations.

A Comprehensive Overview of Gravity Transportation Methods

Gravity transportation, as one of the important methods of ore transportation, plays an indispensable role in mining operations. It uses the ore's own gravity to achieve a full self-weight sliding from the ore dropping point to the transportation roadway, with the advantages of low cost and high efficiency, and has been widely used in many mines. The common gravity transportation methods mainly include the following two types, which are respectively applicable to different ore body conditions.

Steeply Inclined Thin and Extremely Thin Ore Bodies with Shallow Hole Mining

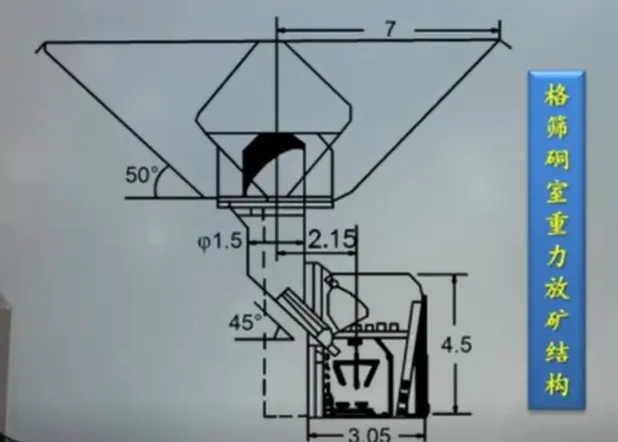

In the mining of steeply inclined thin and extremely thin ore bodies with shallow hole mining, gravity transportation has a unique process. Since shallow hole mining produces fewer large pieces of ore, and a small number of unqualified large pieces can be crushed in the stope and funnel gate, the collapsed ore can smoothly slide along the stope to the bottom structure by its own weight. Subsequently, the ore is loaded into mine cars through ore drawing funnels and gates; in some cases, it can also be loaded into mine cars through manually erected funnel gates. This gravity transportation method also has clear requirements for structural parameters, with the bottom pillar height usually between 5 - 8m, the spacing between funnels being 4 - 6m to 6 - 8m, and the slope angle of the funnel being 45° - 50°. Its advantages are relatively prominent, with less ore in the bottom pillar and a relatively simple bottom structure, which reduces mining costs and complexity to a certain extent. However, it cannot be ignored that it also has some disadvantages, such as limited ore drawing capacity, difficulty in meeting the needs of large-scale and high-efficiency ore drawing, and frequent maintenance of the ore drawing gate, which increases maintenance costs and workload, and has a certain impact on the continuity of production.

There is also a type of artificial ore drawing gate, which has the characteristic of not leaving ore pillars, which greatly improves the ore recovery rate and further simplifies the bottom structure. However, this form has relatively harsh application conditions and is only suitable for steeply inclined thin veins where both the surrounding rock and the ore are stable, and it is usually a high-value vein, which is subject to certain restrictions in practical applications.

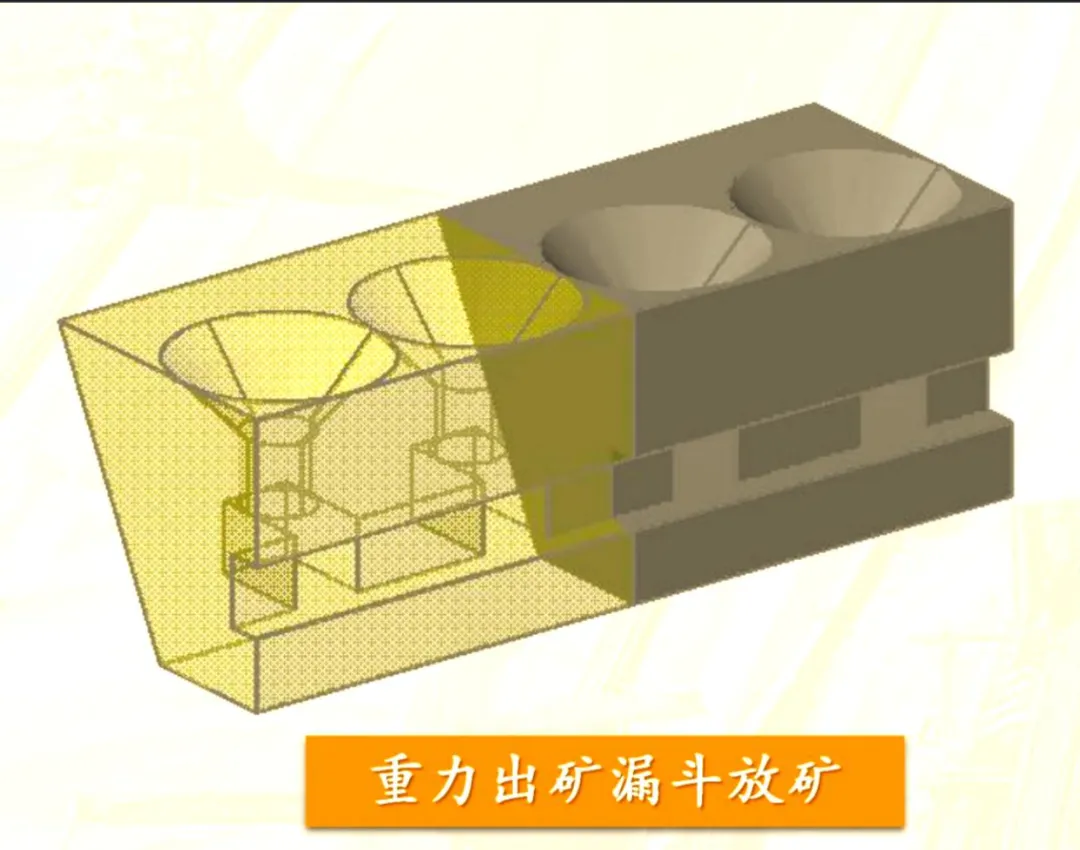

Steeply Inclined Thick Ore Bodies or Gently Inclined Extremely Thick Ore Bodies

For steeply inclined thick ore bodies or gently inclined extremely thick ore bodies, a gravity transportation structure with grizzly chambers is often used. In this structure, the collapsed ore also slides along the stope to the ore drawing funnel by its own weight, and then passes through the grizzly of the grizzly chamber. The grizzly plays a key screening role, and the qualified ore is loaded into the mine car in the transportation roadway through the ore drawing chute and gate. The large pieces of ore that cannot pass through the grizzly will be crushed again on the grizzly, so the grizzly chamber is also called the secondary crushing chamber. The ore pile flowing out of the funnel should not exceed 2/3 of the total area of the grizzly, otherwise it will affect the screening and secondary crushing effect. Generally, the bottom pillar height is 12 - 18m, and the bottom pillar accounts for 20% - 30% of the ore block, and the higher bottom pillar ore content affects the ore recovery rate to a certain extent. The advantage of this method is that it has a large ore drawing capacity, which can meet the ore drawing needs of large-scale mining, and the square frame cost is relatively low, which has certain advantages in economic cost. However, its disadvantages are also obvious, the amount of preparation work is large, a lot of preliminary preparation work is required, and the working conditions are harsh, which has a certain impact on the physical health and work efficiency of the staff.

Application Conditions and Scope of Gravity Transportation

As an important ore transportation method, the application of gravity transportation is not without restrictions, but is subject to the comprehensive constraints of various factors. In-depth exploration of these factors is of key significance for rationally selecting gravity transportation methods, improving mining efficiency, reducing costs, and ensuring production safety.

Affected by Ore Body Factors

The dip angle of the ore body and the nature of the ore are key ore body factors affecting the application of gravity transportation. In terms of the dip angle of the ore body, different mining methods have different requirements for it. When applying the open stope mining method, the dip angle of the ore body is generally not less than 50° - 55° before gravity transportation can be considered. This is because only when such a dip angle is reached can the ore in the stope slide to the bottom structure relatively smoothly with the help of its own gravity, so as to realize efficient transportation. If the dip angle is too small, the ore may not be able to slide down smoothly, resulting in low transportation efficiency and even blockage. In some actual mine mining, if the dip angle of the ore body does not meet the requirements, the forced use of gravity transportation will frequently lead to the accumulation of ore in the stope, which cannot be transported out in time, which seriously affects the mining progress.

When applying the caving mining method, the ore can roll down by gravity along a 65° - 80° inclined surface. The characteristics of the caving mining method determine that the angle requirement for ore rolling is more strict. Only within this angle range can the ore make full use of gravity during the caving process to achieve fast and efficient transportation. The nature of the ore cannot be ignored, including the hardness, size, and shape of the ore. Ore with high hardness is more resistant to friction and collision during gravity transportation, ensuring smooth sliding; while ore with too large size or irregular shape may cause blockage during sliding, affecting transportation efficiency. If the ore hardness is low, it may be broken under the action of gravity, resulting in too much fine powder, which not only increases the difficulty of transportation, but may also cause pollution to the environment.

Considering the Stoping Technology

The compatibility of the stoping technology and gravity transportation largely determines whether gravity transportation can be effectively applied. Different stoping technologies have different requirements and impacts on gravity transportation. In the stoping technology of shallow hole mining, for steeply inclined thin and extremely thin ore bodies, since there are fewer large pieces produced by ore drawing, and they can be crushed in the stope and funnel gate, this creates favorable conditions for gravity transportation. The collapsed ore can smoothly slide along the stope to the bottom structure by its own weight, so as to realize efficient transportation. In the stoping technology of deep hole mining, for steeply inclined thick ore bodies or gently inclined extremely thick ore bodies, the gravity transportation structure with grizzly chambers is used, and it is necessary to consider the screening effect of the grizzly, the efficiency of secondary crushing, and the height of the bottom pillar to ensure the smooth progress of gravity transportation. The aperture size of the grizzly needs to be reasonably designed according to the qualified size of the ore. If it is too large, it will not be able to effectively screen out large pieces of ore, and if it is too small, it may lead to a decrease in the ore passing rate, affecting transportation efficiency.

The ore drawing method and blasting parameters in the mining process also affect gravity transportation. Reasonable ore drawing methods and blasting parameters can crush the ore into suitable sizes, which is convenient for gravity transportation. If the blasting parameters are unreasonable, resulting in excessively large or small ore sizes, it will hinder gravity transportation. Overly large ore blocks may not be able to pass through the grizzly or funnel and require secondary crushing, increasing workload and costs; overly small ore blocks may generate dust during the sliding process, affecting the working environment and worker health.

Analysis of Advantages and Disadvantages of Gravity Transportation

List of Advantages

The advantages of gravity transportation are significant and have important value in mining operations. Taking the gravity transportation structure with grizzly chambers for steep-inclined thick ore bodies or gently inclined extremely thick ore bodies as an example, its advantage of large ore drawing capacity is fully reflected. In some large mines, this gravity transportation method is used to quickly transport a large amount of collapsed ore from the stope, meeting the needs of large-scale production and greatly improving mining efficiency. Compared with other transportation methods, such as electric scraper transportation, when facing a large amount of ore, the ore transportation work of the electric scraper is intermittent and inefficient, while gravity transportation can achieve continuous and efficient ore drawing.

Low cost is also a major outstanding advantage of gravity transportation. In the mining of steep-inclined thin and extremely thin ore bodies with shallow-hole ore drawing, the use of gravity transportation results in less pillar ore, simple structure, and reduced construction and maintenance costs. It does not require complex mechanical equipment and a large amount of manpower, relying only on the ore's own gravity to achieve transportation, reducing equipment purchase, operation, and labor costs. Compared with self-propelled equipment transportation, self-propelled equipment is expensive and requires a large amount of maintenance work, while gravity transportation has a clear competitive advantage in terms of cost.

Explanation of Disadvantages

Despite the many advantages of gravity transportation, its disadvantages cannot be ignored. The large amount of preparation work is a major drawback. When using a gravity transportation structure with grizzly chambers for steep-inclined thick ore bodies or gently inclined extremely thick ore bodies, a large number of roadways need to be excavated, including ore drawing funnels, grizzly chambers, ore passes, etc. The excavation of these roadways not only consumes a lot of manpower, materials, and time, but also increases the initial investment cost. Moreover, there is a large amount of pillar ore, generally with a pillar height of 12 - 18m, and the pillar accounts for 20% - 30% of the ore block's ore content, which means that a large amount of ore is left in the pillar and cannot be recovered in time, reducing the ore recovery rate and wasting resources.

Poor working conditions are also a problem faced by gravity transportation. During the gravity transportation process, the impact during ore drawing and the need for blasting when dealing with ore pass blockages often cause damage to the forehead wall of the ore drawing gate chamber, which not only increases the amount of maintenance work and costs but also poses a threat to the safety of workers. Frequent blasting operations generate a large amount of dust and harmful gases, deteriorating the working environment. Working in such an environment for a long time can cause serious damage to workers' health, such as occupational diseases like pneumoconiosis.

Summary

As an important method of ore transportation, gravity transportation has specific applicable scenarios and unique value in the mining field. It achieves transportation by using the ore's own gravity, and has the advantages of low cost and large ore drawing capacity, playing a key role in the mining of steep-inclined thin and extremely thin ore bodies as well as steep-inclined thick ore bodies or gently inclined extremely thick ore bodies. However, it also has some disadvantages, such as limited ore drawing capacity, a large amount of preparation work, and poor working conditions, which limit its application in a wider range.

Previous Page