Detailed Explanation! Types and Selection of Drill String Combinations — Black Diamond Report

Drilling string combination (combination drilling string), also known as drilling string matching, specifically refers to deep well drilling with large boreholes (such as oil and gas well drilling). It means the way a drill bit of a certain size is matched and connected with drill collars, drill pipes, and square drill pipes of certain sizes during drilling. It is an important issue related to safe, fast, and high-quality drilling.

Drill string combination

- Drilling string combination (drilling string matching): refers to the selection and connection of various drilling tools that make up a well's drill string.

- Lower drilling string combination: refers to the composition of the lowest section of the drill string.

- Drill string: refers to the entire string of drill pipes below the swivel and above the drill bit. It consists of square drill pipes, drill pipes, drill collars, joints, stabilizers, and other drilling tools.

- Reversing drilling tools: changing the original insertion order of some drill collars during drilling to alter the stress conditions of the drilling tools.

- Downhole three tools: refers to the stabilizer, shock absorber, and jar.

- Neutral point of the drill string: the position where the total weight of the drill string minus the weight of the portion applying pressure to the drill bit results in a point that is neither under tension nor compression, called the neutral point of the drill string.

Main types of drilling string combinations

The drill string is the hub connecting the surface and downhole. Different drill string structures and their stress states downhole determine the magnitude and direction of the weight on bit. For example, in directional drilling or when the well deviation is large, the actual weight on bit is smaller than the data shown on the weight indicator. If the drill string combination includes stabilizers, the actual weight on bit is even smaller. Meanwhile, due to the friction between the stabilizer and the wellbore wall, the drill bit's working stability is enhanced, which is beneficial for the drill bit's use.

- (Rigid) full-contact drilling tools: Lower drilling string combination composed of multiple stabilizers with an outer diameter close to the drill bit diameter and large-sized drill collars. Used for anti-deviation and stabilizing well deviation.

- Tower-type drilling tools: Lower drilling string combination composed of drill collars of different diameters, smaller on top and larger below. Used to prevent well deviation.

- Pendulum drilling tools: In an already deviated wellbore, a section of drill collar above the drill bit and below the tangent point acts like a "pendulum." The lateral component of the weight of this drill collar segment—the pendulum force—pushes the drill bit toward and cuts the lower side of the wellbore wall, thereby reducing the well deviation angle. The lower drilling string combination using this principle is called pendulum drilling tools. Used for anti-deviation and correction of deviation.

Increase, decrease, and stabilize deviation drilling string combinations

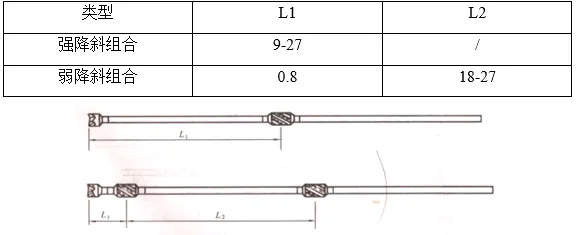

Decrease deviation combination:

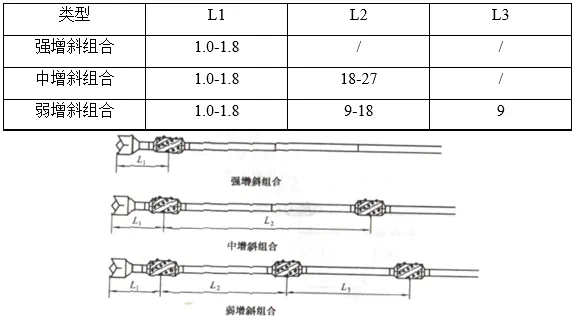

Increase deviation combination:

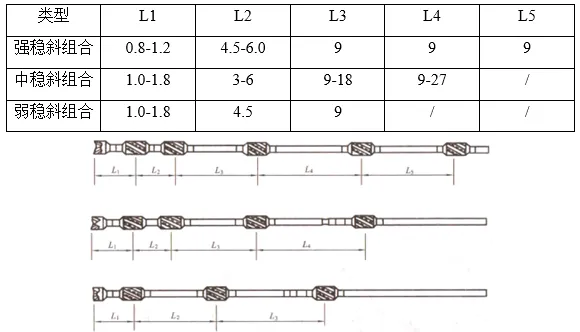

Stabilize deviation combination:

The properties of the drilling string combination vary depending on the placement of stabilizers. Generally, the closer the stabilizer is to the drill bit, the greater the drill bit's deviation increasing force; conversely, the farther it is, the smaller the deviation increasing force. For drilling string combinations with two or more stabilizers, the greater the effective distance between the first and second stabilizers, the greater the drill bit's deviation increasing force; conversely, the smaller the force.

Full-contact drilling string combination

- What is the principle of controlling well deviation with a full-contact drilling string combination? Can it reduce the well deviation angle?

Answer: The causes of well deviation can be summarized into three:

1. Asymmetric cutting of the well bottom by the drill bit;

2. Tilt of the drill bit axis relative to the wellbore axis;

3. Lateral force on the drill bit causing lateral cutting of the well bottom.

The full-contact drilling string combination is designed to overcome the above three causes. Using a full-contact drilling string combination in a well where deviation has already occurred cannot reduce the deviation angle; it can only keep the deviation change very small or unchanged. Therefore, the main function of the full-contact drilling string combination is to control the wellbore curvature, not to control the size of the deviation angle.

- The use of full-contact drilling string combinations should pay attention to the following issues:

Answer: ① Using full-contact drilling tools in a well where deviation has already occurred cannot reduce the deviation angle; it can only keep the deviation angle change (increase or decrease) very small or unchanged. Therefore, the main function of the full-contact drilling string combination is to control the wellbore curvature, not the size of the deviation angle.

- The key to using full-contact drilling tools lies in the word "full," meaning the gap between the stabilizer and the wellbore has a significant impact on the performance of the full-contact drilling string combination. During use, the gap should be kept as small as possible. The designed gap is generally Δd=dh-ds=0.8 to 1.6 mm. During use, due to stabilizer wear, the gap will increase. When the gap Δd reaches or exceeds twice the design value, the stabilizer should be replaced or repaired promptly.

- Another key to maintaining "full" is that the wellbore diameter must not enlarge. This requires good drilling fluid wellbore protection technology. However, even if the drilling fluid protection is poor, wellbore enlargement takes time to occur. As long as a new wellbore is drilled before enlargement, the "full" effect can still be maintained. This requires increasing the drilling speed. Field technicians in China have summarized this concept as "maintain fullness by speed, maintain straightness by fullness."

- When drilling through alternating soft and hard formations or formations with large inclination angles, attention should be paid to appropriately reducing the drilling weight and frequently marking the wellbore to eliminate possible "doglegs."

- Problems caused by the "full-contact" issue of the lower structure using full-contact stabilizers:

Answer: ① Drilling down is prone to obstruction; spiral stabilizers can also cause the drill string to "rotate" in small borehole sections. Minor sticking can often be overcome by controlled "jarring" and "lifting and lowering."

- Starting drilling can cause suction (piston pulling) problems: Due to "full contact," piston pulling during starting in water-sensitive swelling formations has caused uncontrolled gas well blowouts in deviated wells in the Shengli Oilfield, which was a painful lesson. Therefore, it requires good mud inhibition in deviated wells, thin mud cake on the wellbore wall, careful operation to avoid piston pulling, and proper handling if it occurs.

- The sensitivity issue of bent wellbore on drill string stiffness changes: The curvature of the already drilled bent wellbore is fixed. When the drill string combination requires increased rigidity for trajectory control (increasing the number of stabilizers and shortening the spacing between stabilizers), it is easy to encounter obstruction and sticking. Special care is needed when lowering the drill string, and reaming the wellbore is necessary.

It is especially worth reminding that after orienting or adjusting the azimuth, it is very necessary to first use a relatively "soft" rotary table drill string combination to circulate the well.

5. Pendulum Drill String Combination

What is the principle of controlling well inclination with a pendulum drill string combination? Why is the drilling speed very slow when using it?

Answer: When the pendulum swings past a certain angle, a restoring force is generated on the pendulum. If a stabilizer is added at an appropriate position on the lower part of the drill string, which supports against the wellbore wall and suspends the lower drill string, the drill string below the stabilizer behaves like a pendulum and also generates a pendulum force. This pendulum force causes the drill bit to cut the lower side of the wellbore wall, continuously decreasing the wellbore inclination.

The performance of the pendulum drill string combination is particularly sensitive to drilling pressure. Increasing the drilling pressure increases the inclination force but decreases the pendulum force. Further increasing the drilling pressure can bend the drill string below the stabilizer or even create new contact points, completely losing the pendulum combination's effect. Therefore, drilling pressure must be strictly controlled when using the pendulum drill string combination. When the well is not inclined or the inclination is very small, to prevent inclination, drilling pressure must be reduced to perform "weight-on-bit suspension," resulting in very slow drilling speed.

Use of the Pendulum Drill String Combination

Answer: ① The pendulum force of the pendulum drill string combination varies with the size of the well inclination angle. The larger the inclination angle, the greater the pendulum force; if the inclination angle is zero, the pendulum force is also zero. Therefore, the pendulum drill string combination is mostly used to correct wells with already large inclination angles.

- The performance of the pendulum drill string combination is particularly sensitive to drilling pressure. Increasing the drilling pressure increases the inclination force but decreases the pendulum force. Further increasing the drilling pressure can bend the drill string below the stabilizer or even create new contact points, completely losing the pendulum combination's effect. Therefore, drilling pressure must be strictly controlled when using the pendulum drill string combination.

- When the well is not yet inclined or the inclination angle is very small, to continue drilling while maintaining no inclination, drilling pressure must be reduced to perform "weight-on-bit suspension." Because "weight-on-bit suspension" drilling speed is very slow, full stabilizer drill string combinations are mostly used at this time, and the pendulum drill string combination is only used for "weight-on-bit suspension" in vertical well sections with particularly strict trajectory requirements.

- The clearance between the stabilizer and the wellbore has a particularly obvious effect on the performance of the pendulum drill string combination. When the stabilizer diameter decreases due to wear, it should be replaced or repaired promptly.

- Using multiple stabilizers in a pendulum drill string combination requires more complex design and calculation.

Methods to increase the stiffness of the bottom drill string combination

Increase the number of stabilizers;

Shorten the distance between stabilizers;

Use drill collars with large weight and high bending stiffness.

Common drill string combinations for directional wells

Bent sub with downhole motor drill string — build-up drill string

Currently, the most commonly used build-up drill string combination uses a bent sub and downhole motor drill string combination for directional build-up or azimuth adjustment. This build-up drill string combination uses the bent sub to generate an elastic moment on the lower drill string, forcing the downhole motor drill string (screw or turbine) to drive the drill bit to cut laterally, causing the newly drilled wellbore to deviate from the original wellbore axis, achieving directional build-up or azimuth adjustment.

The build-up capability of the build-up drill string depends on the bending angle of the bent sub and the rigidity of the drill collar above the bent sub. The larger the bending angle and the stronger the rigidity of the drill collar above the bent sub, the stronger the build-up capability and the higher the build-up rate. The bending angle of the bent sub should be selected based on the wellbore size, specifications of the downhole motor drill string, and the required build-up rate. The commonly used bent sub angles on site are 1° to 2.5°.

The model of the downhole motor drill string used in the build-up drill string combination should be selected according to the well depth of the build-up or azimuth adjustment section. For well sections within 1000m, turbine or screw drill strings are generally used; for deep directional build-up or azimuth adjustment, high-temperature resistant downhole motors should be used. The build-up drill string combination, drilling parameter design, and drill bit water jet should be designed according to the manufacturer's recommended drilling parameters.

Because the downhole motor drill string has a high rotation speed and requires low drilling pressure (generally 3~8 tons), the drill bit used should not be a sealed bearing bit, especially in shallow, easily drillable soft formations where milling tooth roller bearing bits or suitable composite PDC bits should be used.

Inclination Increasing Drill String

The inclination increasing drill string combination generally uses a double stabilizer drill string combination. The inclination increasing drill string is designed based on the lever principle. It has a near-bit full-size stabilizer as a fulcrum, and the distance between the second stabilizer and the near-bit stabilizer should be determined based on the rigidity (size) of the drill collar between the two stabilizers and the required inclination increase rate, generally 20 to 30 meters. The drill collar between the two stabilizers bends downward under drilling pressure, generating a lateral force on the drill bit, increasing the well inclination angle as the well deepens. The drilling parameters for the inclination increasing drill string combination should be designed based on the specifications of the lower drill string, the distance between the two stabilizers, and the required inclination increase rate. The micro inclination increasing drill string combination has the same downhole stress conditions as the inclination increasing drill string. It mainly reduces the build-up capability by shortening the distance between the near-bit stabilizer and the second stabilizer or reducing the outer diameter of the near-bit stabilizer (worn stabilizer). The micro inclination increasing drill string is used in well sections requiring low inclination increase rates, such as catenary profiles and secondary curve profiles. It can also be used in well sections where surface factors cause the stabilizing drill string to fail to stabilize, resulting in a decreasing inclination trend. Using a suitable micro inclination increasing drill string can achieve ideal stabilization effects.

Stabilizing Drill String

The stabilizing drill string combination uses a rigid full stabilizer drill string structure to increase the rigidity of the lower drill string combination, controlling the bending deformation of the lower drill string under drilling pressure, achieving the effect of stabilizing well inclination and azimuth. Common stabilizing drill string combinations are:

Drill bit ten near drill bit stabilizer ten short drill collar (2~3m) ten stabilizer ten single drill collar (9~10m) + stabilizer sub drill key + drill pipe. For formations with severe azimuth drift due to formation factors, two stabilizers can be connected in series on the drill bit, which can achieve better effects in stabilizing azimuth and well inclination.

Inclination reduction drilling tools

Inclination reduction drilling tools generally use a pendulum drilling tool combination, utilizing the pendulum force generated by the weight of the drilling tools themselves to achieve the purpose of reducing inclination. According to the designed profile's required inclination reduction rate and well inclination angle, the distance between the drill bit and the stabilizer is designed to change the magnitude of the pendulum force of the lower drilling tools; the drilling parameters for the inclination reduction section should limit the drill pressure based on the wellbore size to ensure the inclination reduction effect and make the inclination reduction rate meet the profile requirements.

Inverted drilling tools

When drilling directional wells, considering that rigid drilling tools such as drill collars are not suitable for entering the inclined well section, drill collars or heavy drilling tools are usually placed in the vertical well section, with some drill pipes placed below the drill collars or heavy drill pipes, called inverted drilling tools. Inverted drilling tools are generally used in horizontal well drilling operations, mainly to apply drill pressure.