Detailed Explanation of Ground Pressure Management (Part 3): Working Face Support, Backfill Materials and Collapsing Surrounding Rock, Active and Passive Management — Black Diamond Report

Introduction

In mining engineering, ground pressure management is a crucial task directly related to the safety and efficiency of mine production. As mining activities deepen, ground pressure issues become increasingly prominent. How to effectively manage and control ground pressure to ensure the safe and stable mining of the mine is a challenge that mining engineers must face and solve. The previous two chapters discussed ground pressure management; this chapter is the final one. This article will provide a detailed explanation and discussion on the management of ground pressure through working face support, backfill materials, caving surrounding rock ground pressure management, and the differences between passive and active ground pressure management.

1. Working Face Support

Working face support refers to the auxiliary support methods used during the mining face extraction process when the exposed area is too large and the self-supporting capacity of the ore rock cannot maintain the stability of the goaf. This support is used to meet the spatial stability requirements. Working face support is one of the important means of ground pressure management, aiming to prevent instability of the surrounding rock in the goaf and ensure the safe progress of mining activities.

1. Timber Support

Timber support is one of the earliest methods used in working face support, characterized by low cost, ease of processing, and installation. Timber support mainly includes forms such as cross braces, single props, timber stacks, and frame supports.

Cross Brace Props Using wooden cross braces on the two walls of the goaf to form a support structure to resist the pressure of the surrounding rock.

Single Props Using single wooden poles or columns to support between the roof and floor of the goaf, providing support.

Timber Stack Support Arranging multiple wooden pieces in a certain pattern to form a timber stack structure to enhance the support effect.

Frame Support Using timber to build frame supports, forming a stable support system.

However, with the continuous development and utilization of mineral resources, the shortage of timber resources has become increasingly serious. Additionally, the strength and durability of timber support are limited, gradually restricting its application range.

2. Anchor Rod and Anchor Cable Support

Anchor rod and anchor cable support is an important form of working face support, featuring good support effect, fast construction speed, and relatively low cost. By driving metal anchor rods or long cables into the surrounding rock, the working face surrounding rock is tightly connected with the support structure, forming an integrated stable support system.

Anchor Rod Support Using anchor rods to connect the surrounding rock with the support structure to improve the stability of the surrounding rock. Types of anchor rods include metal anchor rods, resin anchor rods, etc., with length and diameter selectable according to specific engineering needs.

Anchor Cable Support Using anchor cables to connect the working face surrounding rock with deep stable rock layers, forming a stable support structure. Anchor cables are usually used in deep mining or working faces with poor surrounding rock conditions.

The support effect of anchor rods and anchor cables depends on factors such as the material, length, diameter, and construction technology of the anchor rods or cables. In practical applications, selection and design should be based on specific engineering conditions.

3. Metal Props

Metal props are a commonly used form of working face support, characterized by high strength, good durability, and reusability. Metal props are usually made of steel or alloy materials, with large bearing capacity and deformation resistance.

Single Metal Prop Using a single metal prop to support between the roof and floor of the goaf, providing support. The support effect of a single metal prop depends on its material, size, and construction technology.

Composite Support Frame Arranging multiple metal props in a certain pattern to form a composite support frame structure to enhance the support effect. Composite support frames are usually used for large-span or high-stress working faces.

The support effect of metal props is stable and reliable, but the cost is relatively high. In practical applications, selection and design should be based on specific engineering conditions to fully utilize their support effect.

4. Concrete or Shotcrete Support

Concrete or shotcrete support is an important form of working face support, characterized by good support effect, durability, and fast construction speed. By timely spraying or pouring concrete, a stable support structure is formed to resist the pressure of the surrounding rock.

Shotcrete Support Using shotcrete equipment to spray concrete onto the surface of the excavated rock layer, forming a solid support layer. Shotcrete support is suitable for relatively smooth rock surfaces without obvious cracks after excavation.

Concrete Support Pouring concrete onto the surface of the excavated rock layer to form a stable support structure. Concrete support is suitable for uneven rock surfaces or those with cracks after excavation.

The support effect of concrete or shotcrete depends on factors such as the material, strength, construction technology of the concrete, and rock layer conditions. In practical applications, selection and design should be based on specific engineering conditions to fully utilize their support effect.

2. Management of Ground Pressure by Backfill Materials

Management of ground pressure by backfill materials is an effective ground pressure management method. Its principle is to use backfill materials to fill the goaf to limit the deformation of the surrounding rock and pillars, mitigate the hazards of rock movement, and reduce the degree of surface subsidence. Backfill methods include hydraulic sand filling, cemented filling, and paste filling.

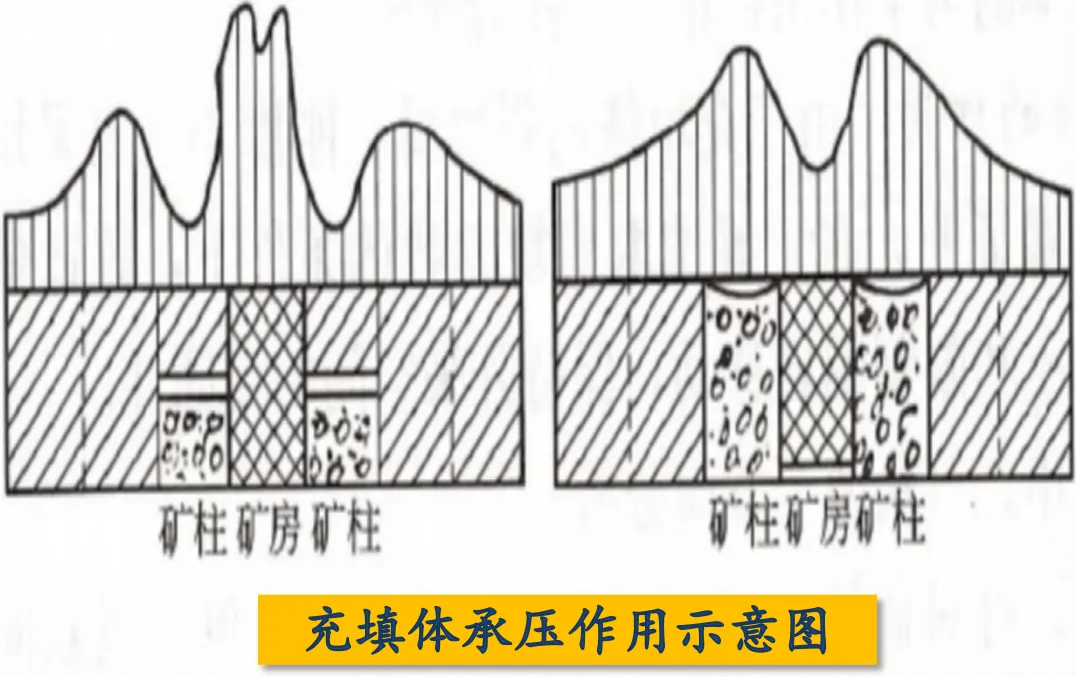

1. Backfill Principle

The basic principle of the filling method is to use filling materials to fill the goaf area, thereby reducing the movement of the surrounding rock of the goaf. When the filling material is filled into the goaf, the surrounding rock of the goaf is supported and restricted by the filling material, significantly inhibiting its movement and deformation. In this way, the filling body can limit the deformation of the surrounding rock and the ore pillar, thereby mitigating the hazards caused by rock movement and effectively reducing the degree of surface subsidence.

2. Classification of Filling Methods

Water-Sand Filling Water-sand filling is one of the earliest filling methods used. It uses a mixture of water and sand as the filling material, which is transported to the goaf through pipelines or chutes for filling. The advantage of water-sand filling is low cost and simple operation, but its disadvantage is low filling density and limited support effect.

Cemented Filling Cemented filling is based on water-sand filling, with the addition of an appropriate amount of cementitious materials (such as cement) to improve the strength and stability of the filling body. The advantage of cemented filling is high strength and good support effect, but its cost is relatively high. In practical applications, economic and technical comparisons need to be made according to specific engineering conditions to determine the most suitable filling method.

Paste Filling Paste filling is a new type of filling method that uses high-concentration paste materials as the filling material. The advantages of paste filling are high filling density, good support effect, and minimal impact on the surface. At the same time, paste filling can achieve synchronous filling and mining, improving mining efficiency. However, the equipment and process of paste filling are relatively complex, and the cost is also higher.

3. Functions of the Filling Body

Limiting Surrounding Rock Deformation The filling body significantly restricts the movement and deformation of the surrounding rock by filling the goaf. This helps maintain the stability of the mining face and prevents instability and collapse of the surrounding rock.

Slowing Rock Movement The filling body can slow down the speed of rock movement and reduce the hazards caused by rock movement. This helps protect underground projects and surface buildings.

Reducing Surface Subsidence By filling the goaf, the filling body can effectively reduce the degree of surface subsidence. This helps protect the surface environment and the safety of human activities.

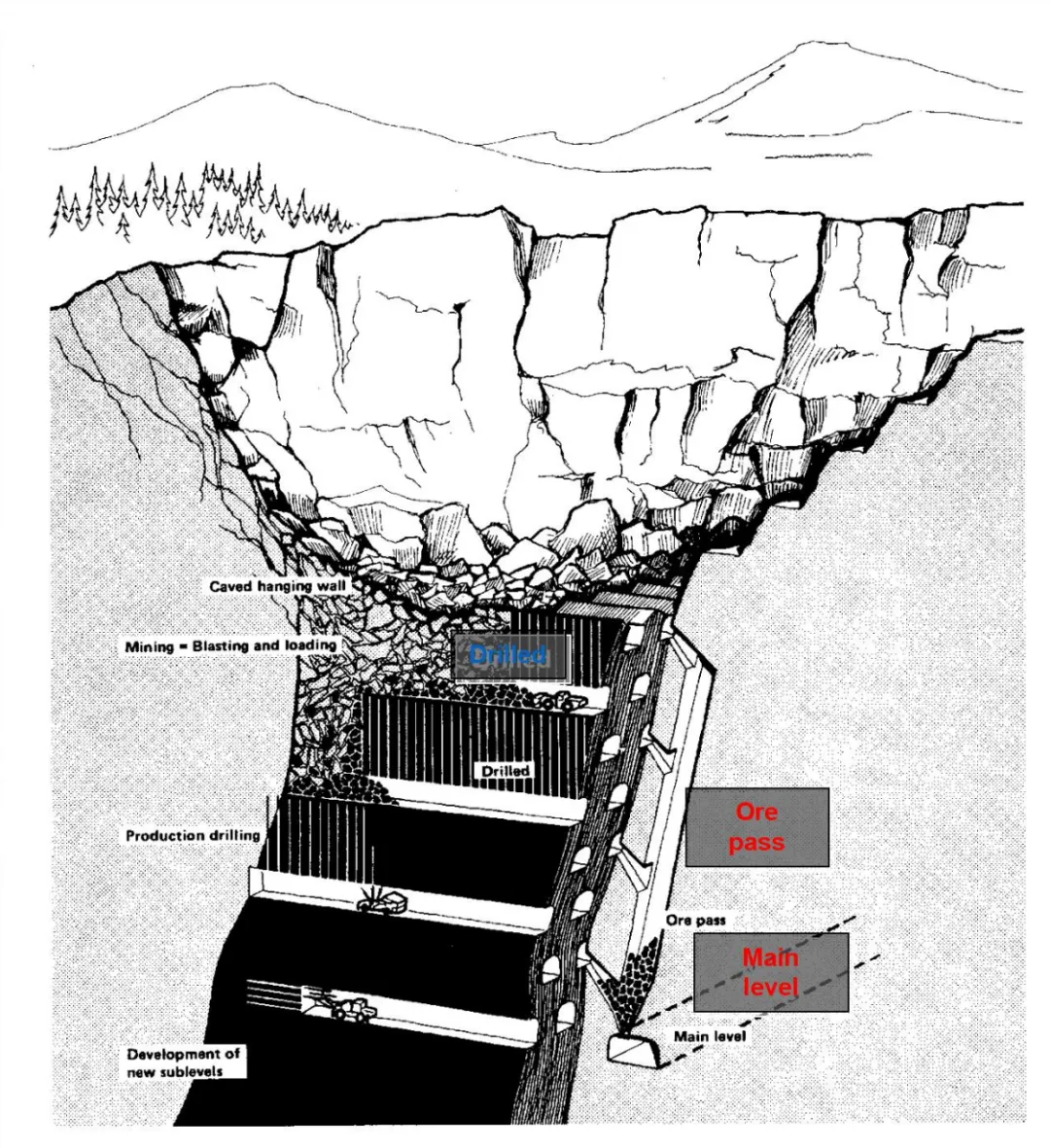

3. Management of Rock Burst in Broken Surrounding Rock

Rock burst management in broken surrounding rock is an active ground pressure management method. Its principle is to release ground pressure by planned collapse of the surrounding rock, thereby eliminating the existence and source of ground pressure. Rock burst management includes two methods: natural collapse and forced collapse.

1. Natural Collapse Method

The natural collapse method uses the gravity of the ore rock itself to cause it to collapse naturally along joints, fractures, and other weak planes. This method is suitable for ore bodies with well-developed joints, many fractures, and easy collapse. The advantage of the natural collapse method is low cost and high efficiency, but its disadvantage is that the collapse range and time are difficult to control, which may cause damage to underground projects and surface buildings.

2. Forced Collapse Method

The forced collapse method uses blasting and other means to plan the collapse of the surrounding rock to release ground pressure. This method is suitable for ore bodies with undeveloped joints, few fractures, or those that are not easy to collapse naturally. The advantage of the forced collapse method is that the collapse range and time are controllable, better meeting the needs of mining engineering. However, the forced collapse method consumes a large amount of blasting materials and energy, resulting in relatively high costs. At the same time, the vibrations and shock waves generated by blasting may cause damage to underground projects and surface buildings, requiring corresponding vibration reduction and protection measures.

4. Differences Between Passive and Active Ground Pressure Management

In ground pressure management, passive and active ground pressure management are two different strategies. They have obvious differences in principles, methods, and effects.

1. Passive Ground Pressure Management

Passive ground pressure management resists the pressure and deformation of the surrounding rock by increasing support structures or taking other measures. This method is a "defensive" strategy, which maintains the stability of the mining face by increasing support structures after the surrounding rock has moved and deformed. Methods of passive ground pressure management include mining face support, anchor and cable support, metal column support, and concrete or shotcrete support. Although these methods can effectively maintain the stability of the mining face, they cannot fundamentally eliminate the existence and source of ground pressure. Therefore, in long-term mining activities, passive ground pressure management may lead to damage and failure of support structures, affecting the safety and efficiency of mining engineering.

2. Active Ground Pressure Management

Active ground pressure management actively manages ground pressure by planned changes in the layout and mining sequence of mining engineering. This method is an "offensive" strategy, which eliminates the existence and source of ground pressure by changing the layout and mining sequence before the surrounding rock moves and deforms. Methods of active ground pressure management include management of ground pressure by filling bodies and rock burst management in broken surrounding rock. These methods can fundamentally eliminate the existence and source of ground pressure, effectively controlling the development of ground pressure and improving the safety and efficiency of mining engineering. However, active ground pressure management requires more precise geological exploration and engineering design, as well as precise control and management of mining activities. At the same time, in some cases, active ground pressure management may cause certain damage and impact to underground projects and surface buildings, requiring corresponding vibration reduction and protection measures.

5. Reasonable Mining Sequence and Ground Pressure Management

A reasonable mining sequence is an important part of ground pressure management. By determining a reasonable mining sequence, effective control and management of ground pressure can be achieved.

1. Factors Affecting Mining Sequence

Determining a reasonable mining sequence requires consideration of multiple factors, including the occurrence conditions of the ore body, geological structure, rock mechanics properties, mining methods, and the safety and economy of mine production. Different ore bodies and mining conditions require different mining sequences to ensure the effectiveness of ground pressure management.

2. Principles of a Reasonable Mining Sequence

(1) Mining from the center towards both sides For ore bodies with a longer strike length, it is generally recommended to mine from the center towards both sides. This is because the pressure in the central part of the ore body is often the greatest. Starting mining from the center can gradually release ground pressure, reducing the risk of ground pressure during subsequent mining processes.

(2) Segmented Mining When mining in segments within the ore body, the principle of mining from top to bottom should be followed. This can avoid the pressure impact from the unmined upper ore body when mining the lower ore body, ensuring the safety and stability of the mining process.

(3) Orderly Extraction When determining the extraction units, the orderliness of the extraction process should be ensured. Avoid simultaneous or disorderly mining of multiple extraction units to reduce hazards caused by concentrated ground pressure and rock movement.

(4) Consider Geological Structures During the mining process, the influence of geological structures should be fully considered. For areas with complex geological structures such as faults and folds, the mining sequence should be chosen cautiously to avoid sudden changes in ground pressure caused by geological structure variations.

3. Optimization Strategies for Mining Sequence

(1) Geomechanical Assessment Before mining, a geomechanical assessment of the ore body should be conducted to understand the rock mechanical properties and ground pressure distribution characteristics. Based on the assessment results, a reasonable mining sequence and support method should be determined.

(2) Real-time Monitoring and Adjustment During the mining process, real-time monitoring of ground pressure changes and rock movement should be conducted. Once abnormal conditions are detected, the mining sequence and support methods should be promptly adjusted to ensure the safety and stability of the mining process.

(3) Adoption of Advanced Technologies and Equipment With the continuous development of mining technology, more advanced technologies and equipment are being applied in mining engineering. By adopting these technologies and equipment, more precise control and management of ground pressure can be achieved, improving mining efficiency and safety.

Conclusion

Ground pressure management is a crucial task in mining engineering. By adopting strategies such as mining face support, ground pressure management through backfill, ground pressure management of caved surrounding rock, and determining a reasonable mining sequence, the development of ground pressure can be effectively controlled, enhancing the safety and efficiency of mining engineering. At the same time, selecting appropriate ground pressure management methods according to specific engineering conditions and requirements is also essential.