Ore Deposit Element — Black Diamond Broadcast

In the field of mining, the ore body burial elements are like the cornerstone, bearing the planning and implementation of the entire mining operation. These elements cover key information such as the strike, dip direction, dip angle, thickness, extension, and burial depth of the ore body. They precisely depict the spatial position and morphological characteristics of the ore body underground, serving as indispensable important bases for mining engineers when developing deposits, selecting mining methods, and planning mine production.

The impact of ore body burial elements on mining engineering is comprehensive and profound. From a macro perspective, it directly determines the choice of mining method—whether to use open-pit mining, underground mining, or a combination of both. Different mining methods have significant differences in cost, efficiency, safety, and environmental impact. For example, for shallowly buried, large-scale ore bodies, open-pit mining usually has the advantages of low cost and high efficiency; whereas for deeply buried ore bodies, underground mining is more preferred.

From a micro perspective, elements such as ore body thickness and dip angle affect the specific design of mining methods. Extremely thin and extremely thick ore bodies require vastly different mining methods; horizontal and gently dipping ore bodies have completely different requirements in terms of mine layout and ore transportation compared to steeply dipping ore bodies. At the same time, the extension depth and burial depth of the ore body also affect the mine development system, including the layout and construction of shafts, declines, and drifts.

With the continuous advancement of mining technology, precise detection and analysis of ore body burial elements have become increasingly important. High-precision geological exploration technologies, such as 3D seismic exploration and geological radar, can provide us with more detailed and accurate ore body information, enabling mining engineers to formulate more scientific and reasonable mining plans, improve resource recovery rates, reduce mining costs, and ensure safe production and sustainable development of mines. Therefore, in-depth research on ore body burial elements has significant practical significance and value; it is the key to achieving efficient, safe, and environmentally friendly mining in mining engineering.

Ore Body Burial Elements

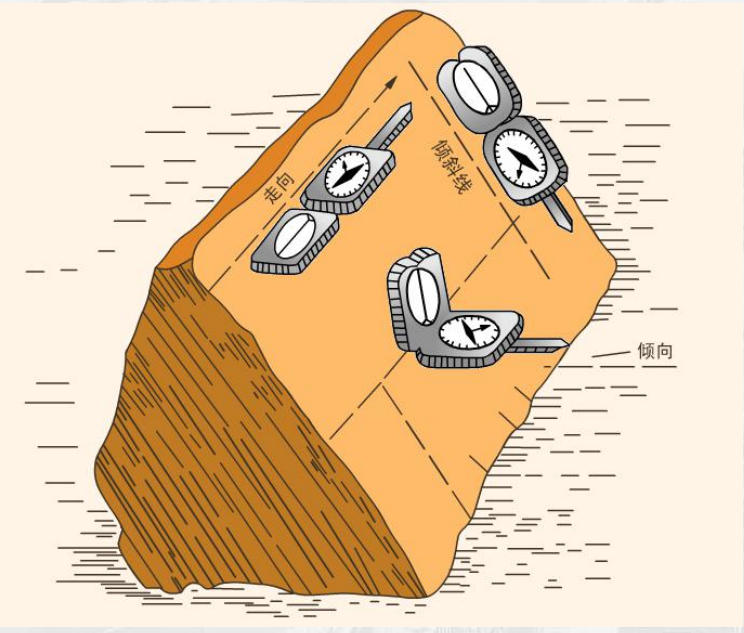

- Strike, Dip Direction, and Dip Angle

Strike is a key element that determines the horizontal extension trend of the ore body. It refers to the line where the ore body plane intersects any horizontal plane, and the angle between the strike line and the true north direction is used to represent the specific value of the strike. For example, in a certain metal mining area, through high-precision geological measurement, it was found that the angle between the ore body's strike line and the true north direction is 45°, indicating that the ore body extends in a specific direction on the horizontal plane. Strike is of great significance for mining engineering planning as it directly affects the layout direction of development drifts. If the strike is not accurately determined, it may lead to unreasonable drift layout, increasing mining costs and difficulties. For instance, in underground mining, if the drift layout does not match the ore body's strike, additional connecting drifts may need to be excavated, which not only consumes a large amount of manpower, material resources, and time but may also affect mining efficiency and safety.

Dip direction represents the direction in which the ore body extends downward and is precisely expressed by the angle between the horizontal projection of the dip line and the true north direction. Taking a practical lead-zinc mine as an example, detailed exploration showed that the ore body's dip direction angle is 135°, clearly demonstrating the ore body's inclined extension trend in three-dimensional space. Dip direction plays an important guiding role in mining engineering and is closely related to the choice of mining methods. Ore bodies with different dip directions require significantly different mining processes and equipment choices. For gently dipping ore bodies, methods such as room and pillar mining may be more suitable, facilitating ore transportation and stope support; for steeply dipping ore bodies, methods like sublevel caving may be needed, utilizing the ore's own weight for efficient extraction. Additionally, dip direction affects ventilation system design; reasonable dip analysis helps optimize ventilation routes, ensuring air quality and safety in underground operations.

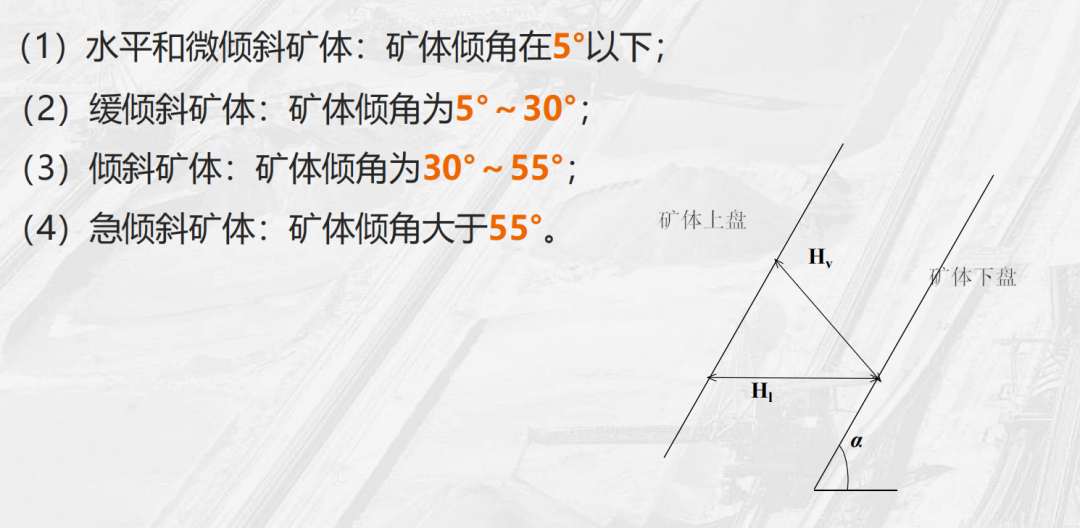

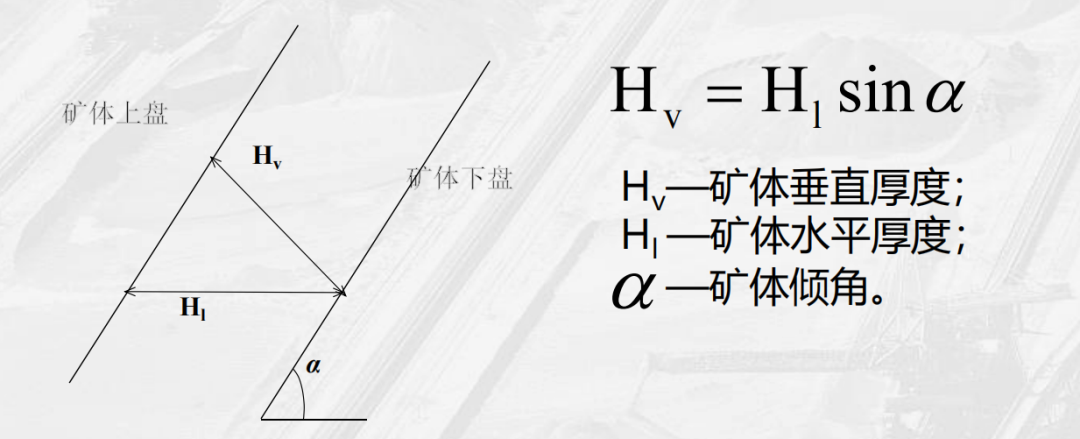

Dip angle plays an extremely important role in ore body mining, determining the ore transportation method and stope stability. Horizontal and gently dipping ore bodies have dip angles below 5°, making mining relatively simple. Various tracked or trackless transportation equipment can directly enter the stope. For example, in some small-scale placer gold mining, due to the small dip angle, small loaders and transport vehicles can conveniently transport ore. Gently dipping ore bodies with dip angles between 5° and 30° can use manual labor or mechanical equipment such as electric rakes and conveyors to transport ore. For instance, in a small lead-zinc mine, mining of gently dipping ore bodies mainly relies on electric rakes to rake ore to transport drifts, then conveyors to move it out. Inclined ore bodies with dip angles between 30° and 55° can use chutes, slides, or explosive throwing methods to transport ore by gravity. In some non-ferrous metal mines, inclined ore bodies are often mined using chutes to slide ore to lower drifts, improving ore extraction efficiency. Steeply dipping ore bodies with dip angles greater than 55° can use gravity to slide ore along the footwall, greatly reducing ore transportation difficulty and cost. However, steeply dipping ore bodies have more prominent stope stability issues during mining, requiring effective support measures to ensure mining safety.

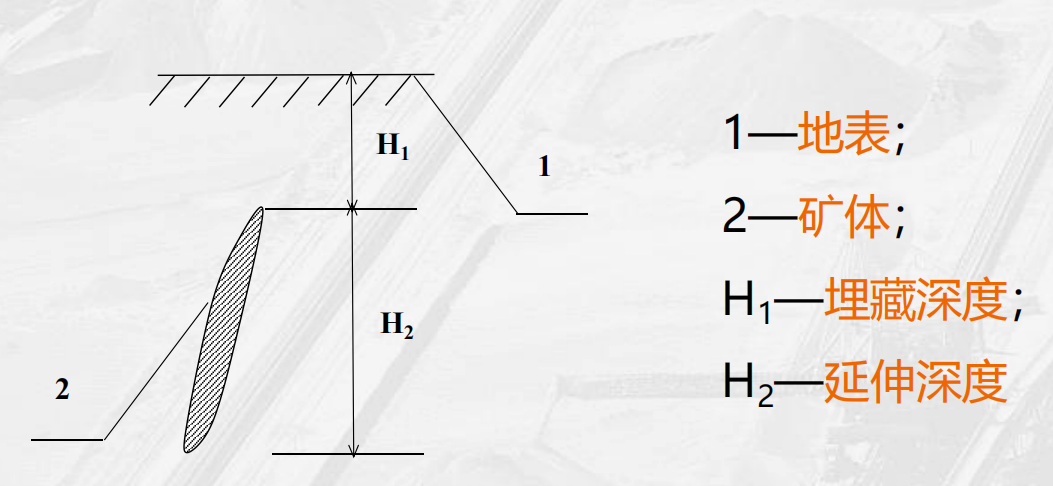

2. Burial Depth and Extension Depth

Burial depth is the vertical distance from the surface to the upper boundary of the ore body, playing a decisive role in the choice of mining method. When the ore body burial depth is shallow, open-pit mining is usually preferred. Open-pit mining has advantages such as low mining cost, high efficiency, and large production scale. For example, some large open-pit coal mines in China, such as the Shanxi Pingshuo open-pit coal mine, use large excavators and trucks for large-scale mining due to shallow coal seam burial, with annual mining volumes reaching tens of millions of tons. Open-pit mining also facilitates the use of advanced mining technologies and equipment, improving resource recovery rates. However, open-pit mining also has drawbacks, such as significant surface environmental damage, occupying large land resources, and generating waste rock and tailings that need proper disposal; otherwise, they can severely impact the surrounding ecological environment.

When the ore body is buried at a greater depth, underground mining becomes the inevitable choice. Underground mining requires complex shaft and tunnel construction, including vertical shafts, inclined shafts, and drifts, to form access routes to the ore body. During underground mining, a series of technical challenges such as ventilation, drainage, and support must be addressed to ensure the safety of miners and the smooth progress of production. For example, in some deep metal mines, due to the great burial depth and high ground pressure, high-strength support materials and advanced support technologies are needed to maintain the stability of the tunnels; at the same time, to ensure the quality of underground air, a complete ventilation system must be established to deliver fresh air to each working face. Although underground mining has relatively high costs and lower efficiency, it can effectively avoid large-scale damage to the surface environment.

The extension depth refers to the vertical distance between the upper and lower boundaries of the ore body, playing an irreplaceable and important role in evaluating the ore body's resource quantity. Accurately grasping the extension depth of the ore body helps mining engineers reasonably plan mining schemes, avoiding waste and loss of resources. By analyzing the extension depth, the mining sequence and scope can be determined. For ore bodies with large extension depths, segmented mining can be adopted to gradually advance downward, improving mining efficiency and resource recovery rate. Additionally, the extension depth affects the selection and arrangement of mining equipment. In deep mining, due to factors such as ground pressure and temperature, mining equipment suitable for deep environments must be chosen, such as drilling machines and loaders with high strength, high temperature resistance, and high pressure resistance.

In actual mining operations, the detection and analysis of extension depth require the comprehensive use of multiple technical methods. For example, obtaining core samples through drilling to analyze the geological characteristics and extension of the ore body; using geophysical exploration methods such as seismic and electromagnetic surveys to detect the deep structure of the ore body; combining geological modeling technology to accurately simulate and predict the extension depth. Only by accurately grasping the extension depth can scientific mining and sustainable development of the mine be achieved.

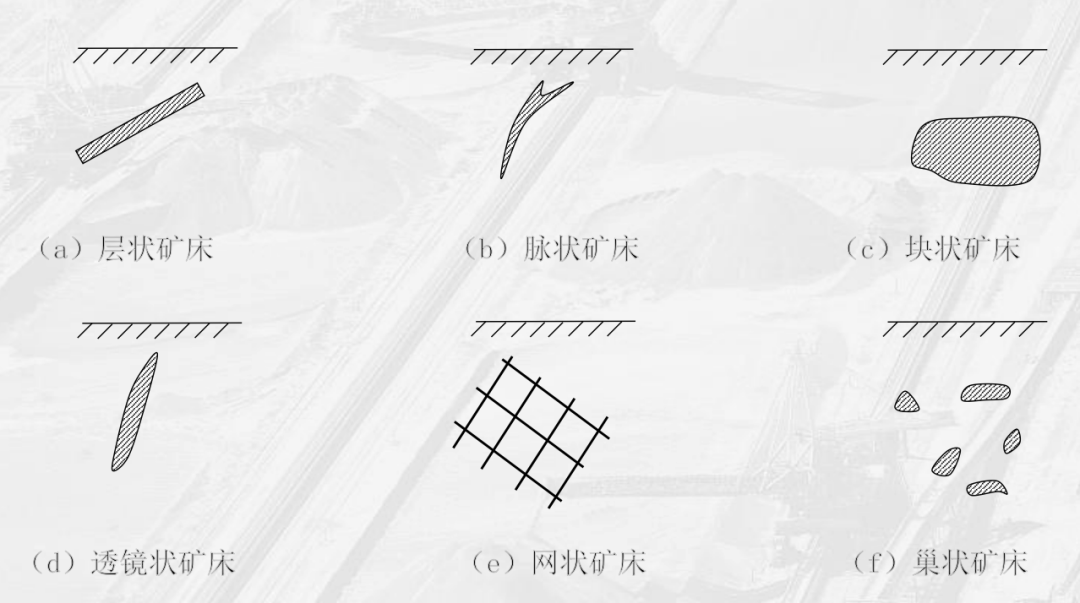

3. Diverse Ore Body Shapes and Their Impact

Stratiform deposits are mostly sedimentary or metamorphosed sedimentary deposits with distinct characteristics. These deposits are usually large in scale, have stable occurrence conditions, stable composition of useful mineral components, and relatively uniform content. They are common in ferrous metal deposits, such as some large iron ore deposits. Taking a large stratiform iron ore deposit as an example, its ore body is distributed in layers, with strike lengths reaching several thousand meters, thickness stable at several tens of meters, and uniform ore grade, making the mining process relatively simple and efficient. When mining stratiform deposits, mature mining methods such as longwall mining are usually adopted. This method fully utilizes the layered characteristics of the ore body to achieve large-scale and high-efficiency mining. Longwall mining arranges longwall faces in the ore body, using coal shearers and other equipment for cutting, scraper conveyors for coal transport, and hydraulic supports for roof support, mechanizing mining, transport, and support operations, greatly improving mining efficiency and safety. Meanwhile, due to the stable occurrence conditions, ore dilution and loss during mining are relatively small, which helps improve resource recovery.

Vein deposits are mainly formed by hydrothermal and pneumatolytic processes, with minerals filling fractures in the crust. They often show alteration phenomena at the contact with the surrounding rock, have unstable occurrence conditions, and uneven content of useful components. Many non-ferrous, rare, and precious metal deposits belong to this type. For example, a tungsten vein deposit has an ore body distributed in veins, with widths ranging from several meters to tens of meters, and variable strike and dip. When mining vein deposits, special attention must be paid to changes in the veins. Due to unstable occurrence conditions, ore dilution and loss are common during mining. To reduce dilution and loss, advanced exploration technologies such as geological radar and transient electromagnetic methods are used to accurately grasp the strike, dip, and thickness variations of the veins, enabling reasonable layout of mining areas and mining sequence. Additionally, mining methods and processes need to be flexibly adjusted according to the actual vein conditions, such as segmented mining and pillar mining, to ensure efficient ore extraction and full resource recovery. Moreover, because of alteration at the contact with surrounding rock and poor stability of the surrounding rock, support measures must be strengthened to ensure mining safety.

Massive deposits are mainly formed through filling, contact metasomatism, segregation, and vaporization processes. Their ore bodies vary in size and shape, appearing as irregular lenses, nests, or stocks, with indistinct boundaries between the ore body and surrounding rock. Some non-ferrous metal deposits (copper, lead, zinc, etc.) belong to this type. Taking a copper deposit as an example, its ore body is distributed in a massive form with irregular shapes and blurred boundaries with the surrounding rock. Mining massive deposits requires relatively complex techniques. Due to irregular ore body shapes, advanced mining technologies and equipment such as large-diameter deep hole mining and staged caving are used to achieve efficient mining. Large-diameter deep hole mining arranges large-diameter deep holes in the ore body, using large-diameter drilling equipment and blasting materials to achieve large-scale ore breakage and extraction, improving mining efficiency. Meanwhile, because of indistinct boundaries with surrounding rock, advanced ore dressing technologies such as flotation, gravity separation, and magnetic separation are used to selectively process ore, improving ore grade and recovery. Additionally, ground pressure management is an important issue during massive deposit mining, requiring effective ground pressure monitoring and control technologies to ensure safety.

Besides the common ore body shapes mentioned above, there are also lens-shaped, net-like, and nest-like deposits. Lens-shaped deposits resemble lenses, with large variations in scale and occurrence; net-like deposits consist of multiple interwoven veins with complex morphology; nest-like deposits occur in nests with relatively small ore body scale. These ore body shapes present certain difficulties during mining. For example, lens-shaped deposits, due to their special shape, are prone to ore loss and dilution during mining, requiring special mining methods and processes such as segmented stoping and backfilling to ensure effective ore extraction. Net-like deposits, due to interwoven veins, are difficult to mine and require precise understanding of vein distribution to reasonably arrange mining tunnels and working faces, improving mining efficiency and resource recovery. Nest-like deposits, due to their small scale, have relatively high mining costs and require efficient mining equipment and technologies to reduce costs and improve economic benefits.

4. Ore Body Thickness Classification and Significance

In the steel industry, there are clear classification standards for ore body thickness. Extremely thin ore bodies have an average thickness of less than 0.8m. Due to their extreme thinness, mining these ore bodies is challenging and often requires special mining methods and equipment, such as the cut-and-fill method. During ore extraction, part of the surrounding rock must also be excavated to ensure the stability of the mining site. Thin ore bodies have a thickness of 0.8 - 5.0m, and appropriate mining methods can be selected based on specific conditions, such as shallow hole ore retention or room and pillar methods. Medium-thick ore bodies range from 5.0 - 15.0m in thickness; these have relatively favorable mining conditions and can use more efficient mining methods like sectional mining or staged stoping. Thick ore bodies, with thicknesses of 15.0 - 50.0m, typically employ large-scale mining equipment and efficient methods such as bottomless or bottom-supported caving methods to achieve large-scale extraction. Extremely thick ore bodies, thicker than 50.0m, require comprehensive consideration of ground pressure, ventilation, transportation, and other factors, using advanced mining technologies and equipment like large-diameter deep-hole mining and staged natural caving methods.

In the non-ferrous metals and gold industries, the classification of ore body thickness differs slightly from that in the steel industry. Extremely thin ore bodies also have an average thickness of less than 0.8m. However, due to the higher value of non-ferrous metals and gold, mining these ore bodies places greater emphasis on resource recovery and utilization, often employing more refined mining methods and beneficiation processes. Thin ore bodies range from 0.8 to 2.0m, medium-thick ore bodies from 2.0 to 5.0m, thick ore bodies from 5.0 to 20.0m, and extremely thick ore bodies exceed 20.0m. Different thicknesses of ore bodies in the non-ferrous metals and gold industries require selecting appropriate mining methods and technologies based on the specific conditions of the ore body and the value of the ore to maximize economic benefits.

Ore body thickness significantly impacts the requirements for mining processes and equipment. Extremely thin and thin ore bodies, due to their limited thickness and restricted mining space, limit the use of large mining equipment. Mining these ore bodies typically requires small, flexible equipment such as small drilling machines and loaders. Additionally, the narrow mining space poses challenges for ground support and ventilation, necessitating special support methods and ventilation systems to ensure safety and a good working environment. Conversely, thick and extremely thick ore bodies, with ample mining space, can utilize large, efficient mining equipment like large drilling jumbos and large shovels to improve mining efficiency. However, as ore body thickness increases, ground pressure also rises, demanding higher stability and support requirements. Advanced ground pressure monitoring and control technologies, along with high-strength support materials and structures, are needed to ensure safe mining operations. Moreover, the choice of mining methods varies greatly with ore body thickness, requiring comprehensive consideration of ore properties, surrounding rock stability, and mining costs to select the most suitable mining method for efficient, safe, and economical extraction.

Measurement and Exploration Techniques of Ore Body Occurrence Elements

- Traditional Measurement Methods

Geological mapping is a fundamental task that infers the occurrence elements of underground ore bodies through detailed observation and measurement of surface geological phenomena. During geological mapping, geologists use tools such as geological compasses, leveling instruments, and total stations to precisely measure the attitude of rock layers and the terrain. The geological compass measures the strike, dip direction, and dip angle of rock layers; the leveling instrument measures elevation changes; and the total station is used to measure coordinates of control points. These measurements are crucial for drawing geological maps, analyzing geological structures, and inferring the location and shape of ore bodies. For example, in the exploration of a lead-zinc deposit in a mountainous area, geologists recorded detailed information on stratigraphic distribution, folds, and faults. Analysis of this data led to the preliminary inference that the ore body might be hosted in a specific stratum and distributed along certain structural lines. Subsequent exploration confirmed this inference, providing important basis for later mining operations.

Drilling is one of the important methods for obtaining underground geological information. It involves drilling holes in rock formations to collect core or cuttings samples to understand the geological structure and distribution of mineral resources underground. In measuring ore body occurrence elements, drilling can directly reveal key information such as ore body shape, grade, and thickness. Core drilling obtains intact core samples that visually display rock characteristics and grade distribution; cuttings drilling analyzes the chemical and mineral composition of the cuttings to reveal the chemical makeup and mineralogy of underground strata. Drilling technology is widely used in deep resource exploration of non-ferrous metal mines. Through drilling, the vertical and horizontal extension of ore bodies and their contact relationships with surrounding rock can be determined, providing accurate data support for mine design. For example, in the exploration of a copper mine, numerous core samples were obtained through drilling. Analysis showed the ore body was lens-shaped, with thickness varying from several meters to tens of meters, and ore grade differing in various parts. This information provided important basis for selecting mining methods and planning mining sequences.

Trenching refers to excavating pits or tunnels on or near an ore body to directly observe and sample the ore body and its surrounding rock. It includes exploration adits, shafts, and declines. Trenching can directly reveal the spatial distribution, geometric characteristics, scale, and ore quality of the ore body, facilitating detailed geological mapping, ore sampling, and engineering testing. When the ore body is well exposed at the surface or the deposit exposure conditions are favorable, trenching can provide direct geological data, revealing the continuity and variation of the ore body in detail. Geological experts can conduct detailed geological mapping inside exploration tunnels, collect representative ore samples for analysis, and perform engineering tests to directly obtain relevant evidence of the ore body. However, trenching has drawbacks such as high construction costs, long durations, and strict requirements on geological conditions and equipment, so it is mainly used in the detailed exploration stage. For example, during the detailed exploration of a gold mine, trenching was used to excavate exploration adits, directly observing the ore body's shape and occurrence, collecting representative ore samples for analysis, and accurately determining ore grade and mineral composition, providing reliable basis for subsequent mine development.

2. Modern Geophysical Exploration Technologies

Geological radar is a non-destructive testing technology that uses electromagnetic waves to detect underground structures. It obtains electrical property information of underground media by transmitting and receiving high-frequency electromagnetic waves. When the transmitter emits electromagnetic waves underground, these waves propagate through the underground media and reflect upon encountering interfaces of different densities. By receiving these reflected signals, information about underground structures can be obtained, enabling the detection of the depth and location of underground ore bodies. Geological radar has the advantages of fast detection speed and high resolution, allowing quick and accurate detection of the existence, location, and depth of ore bodies, which plays an important role in improving resource development efficiency. In mining operations, geological radar can be used to detect the distribution, burial depth, and morphology of underground ore bodies, providing important basis for mining planning and operations. With technological advancements, geological radar continues to improve in detection accuracy and resolution, providing more reliable technical support for underground ore body detection. For example, during the mining process of a certain metal mine, geological radar was used to detect the surrounding mining area, timely discovering potential ore body branches and faults, avoiding safety accidents during mining and improving ore recovery rates.

Magnetic detection is a method that uses changes in the Earth's magnetic field to detect magnetic differences in underground rock bodies. Different rocks and ore bodies have different magnetic properties, which cause local variations in the Earth's magnetic field, forming magnetic anomalies. By measuring these magnetic anomalies with high-precision magnetometers, it is possible to infer the presence of ore bodies underground as well as their location, shape, and scale. In lead-zinc ore exploration, magnetic detection is very effective for magnetic ore bodies such as magnetite and hematite. By analyzing the characteristics of magnetic anomalies, the boundaries and trends of ore bodies can be determined, providing guidance for subsequent exploration and mining work. With continuous development of magnetic exploration technology, the use of high-precision magnetometers and advanced data processing techniques improves the accuracy and interpretability of magnetic anomaly identification, further enhancing the accuracy and reliability of magnetic detection. For example, in the exploration of a certain iron mine, magnetic detection technology was used to accurately delineate the range of the ore body through analysis of magnetic anomalies, providing clear targets for subsequent drilling and mining operations.

Electrical detection is a technology that uses the electrical property differences of underground rocks to detect ore bodies. It is based on the penetration and conduction characteristics of electric current in underground metal ore bodies, detecting the distribution and morphology of underground metal ore bodies by measuring changes in the geoelectric field. Different rocks and ore bodies have different electrical parameters such as resistivity and dielectric constant. When an electric field is applied underground, these electrical differences cause changes in the electric field distribution. By measuring these changes, the presence and characteristics of underground ore bodies can be inferred. Electrical detection includes shallow electrical methods and medium-to-deep electrical methods, suitable for exploring ore bodies at different depths and ranges. Electrical detection plays an important role in searching for concealed ore bodies. By analyzing electrical detection results, further information on the depth, shape, and grade of underground metal ore bodies can be determined. Electrical exploration technology is developing towards high resolution and automation, improving exploration efficiency and interpretation accuracy. For example, in the exploration of a certain copper mine, electrical detection technology was used to analyze resistivity data and successfully discover deep concealed ore bodies, providing new resource guarantees for the sustainable development of the mine.

Radioactive detection utilizes the enrichment and decay characteristics of radioactive isotopes in underground metal ore bodies, detecting the distribution and morphology of underground metal ore bodies by measuring changes in the concentration of radioactive isotopes. Some metal ore bodies, such as uranium ore, are inherently radioactive or coexist with radioactive elements. By measuring changes in underground radioactivity intensity, the presence, location, and extent of ore bodies can be determined. Radioactive detection features high precision and high sensitivity, enabling effective detection of underground metal ore bodies. In mineral resource exploration, radioactive detection can serve as an auxiliary method combined with other exploration techniques to improve accuracy and reliability. By analyzing radioactive detection results, further information on the depth, shape, and grade of underground metal ore bodies can be obtained. For example, in the exploration of a certain uranium mine, radioactive detection technology was used to quickly delineate the distribution area of uranium ore by measuring radioactivity intensity, laying the foundation for subsequent detailed exploration and mining work.

3. Technical Comparison and Selection

Traditional measurement methods, such as geological mapping, can intuitively obtain surface geological information, providing a basis for subsequent exploration, but have limited ability to acquire information on deep ore bodies; drilling can directly obtain underground core samples to accurately understand ore body characteristics, but it is costly, inefficient, and causes significant environmental damage; trenching allows direct observation of ore bodies but is difficult to construct, expensive, and only suitable for specific geological conditions and exploration stages.

Modern geophysical exploration technologies: geological radar has the advantages of high resolution and rapid detection, effectively detecting shallow ore bodies but is greatly affected by geological conditions and has limited capability for deep ore body detection; magnetic detection is effective for magnetic ore bodies, low cost, and efficient but is susceptible to surface interference and complex geological environments; electrical detection has good detection effects for ore bodies with different electrical properties and can be used for ore bodies at various depths, but data interpretation is relatively complex; radioactive detection has unique advantages for radioactive ore bodies or those coexisting with radioactive elements but has a narrow applicable range.

In actual exploration work, appropriate measurement and exploration technologies should be selected based on specific conditions. First, consider the type and characteristics of the ore body: for magnetic ore bodies, magnetic detection is preferred; for ore bodies with significant electrical differences, electrical detection may be more effective; for radioactive ore bodies, radioactive detection technology is used. Geological conditions are also important considerations. In areas with complex terrain and variable geological structures, geological radar may be interfered with, and the construction difficulty of drilling and trenching increases, requiring comprehensive consideration of the feasibility of various technologies. The exploration stage also affects technology selection. During the preliminary survey stage, cost-effective and efficient geophysical exploration technologies such as geological radar, magnetic, and electrical methods are usually used for large-area preliminary detection to delineate areas where ore bodies may exist; during the detailed survey stage, more accurate methods such as drilling and trenching are needed to obtain detailed ore body information, providing a basis for mine design and mining. Additionally, economic cost and time requirements must be considered, selecting cost-effective and efficient technical solutions while ensuring exploration accuracy to improve economic benefits. For example, in the exploration of a polymetallic mine in a mountainous area, geological radar and magnetic methods were first used for large-area preliminary detection to delineate possible ore body areas; then, drilling and trenching methods were used for detailed exploration in key areas to obtain accurate ore body burial element information; during exploration, electrical and radioactive detection technologies were also combined to gain a more comprehensive understanding of ore body characteristics, ultimately formulating a scientific and reasonable mining plan.

The Impact of Ore Body Burial Elements on Mining

- Choice of Mining Methods

The burial elements of the ore body play a decisive role in the selection of mining methods, with burial depth and ore body scale being two key considerations. When the ore body is shallowly buried, usually within 200 meters, and the ore body scale is large, open-pit mining is often the preferred option. Taking some large open-pit coal and metal mines in China as examples, such as the Pingshuo open-pit coal mine in Shanxi and some iron mines in Anshan, Liaoning, these mines have shallowly buried ore bodies. Through large-scale open-pit mining, they can fully utilize the advantages of open-pit mining, including high production capacity, low mining costs, low labor intensity, high production efficiency, simple mining processes, and ease of mechanization and automation. At the Pingshuo open-pit coal mine, large excavators, trucks, and other equipment are used to achieve efficient coal mining, with an annual mining volume reaching tens of millions of tons, greatly enhancing coal supply capacity.

When the ore body is deeply buried, exceeding 200 meters, or when the ore body scale is small and the shape is complex, underground mining becomes the inevitable choice. Underground mining is suitable for various complex geological conditions and can effectively mine deep ore bodies. For example, in some deep metal mines, such as certain copper mines in Yunnan and tungsten mines in Jiangxi, due to the deep burial of the ore bodies, underground mining methods are adopted. By constructing shafts, inclined shafts, and other underground workings, mining operations are carried out deep underground. Although underground mining is more difficult, has relatively lower production efficiency, and higher costs, it can effectively protect the surface environment and reduce ecological damage.

In addition to burial depth and ore body scale, the occurrence and shape of the ore body also have an important impact on the choice of mining methods. For ore bodies with simple occurrence and small dip angles, both open-pit and underground mining have their applicable situations; for ore bodies with complex occurrence and large dip angles, underground mining may be more suitable. For ore bodies with regular shapes such as massive or stratiform, the choice of mining method is relatively clear; for irregular shapes such as vein or lens-shaped ore bodies, a comprehensive analysis and judgment based on specific conditions is required. For example, in the mining of a certain vein-type lead-zinc mine, due to the irregular shape and large dip angle of the ore body, an underground segmented mining method was adopted, effectively improving ore recovery and reducing mining costs.

2. Customization of Mining Processes

The hardness, structure, and thickness of the ore body significantly influence the choice of ore extraction processes. For ore bodies with high hardness, such as quartzite-type gold deposits, drilling and blasting methods are usually required for ore extraction. In such cases, drilling equipment and blasting materials should be reasonably selected based on the hardness and structure of the ore body. For example, for extremely hard ore bodies, high-power drilling jumbos and high-energy explosives may be needed to ensure effective ore fragmentation. For ore bodies with lower hardness, such as some clay deposits, mechanical excavation can be used for ore extraction, which can improve mining efficiency and reduce costs. Regarding ore body thickness, thicker ore bodies can use deep-hole blasting methods to achieve large-scale ore extraction; thinner ore bodies are more suitable for shallow-hole blasting or other special ore extraction methods to reduce ore loss and dilution.

The dip angle, thickness, and terrain conditions of the ore body determine the choice of transportation processes. For horizontal and gently inclined ore bodies, due to the difficulty of ore transportation, rail or trackless transport equipment is usually used. In some small-scale placer gold mining, due to the small dip angle of the ore body, small loaders and transport vehicles can conveniently handle ore transportation. For gently inclined ore bodies, mechanical equipment such as electric rakes and conveyors can be used for transportation. In a small lead-zinc mine, the mining of gently inclined ore bodies mainly relies on electric rakes to rake ore to the transport drifts, then conveyors transport it out. For inclined and steeply inclined ore bodies, chutes, slides, or forceful throwing methods can be used to transport ore by gravity. In some non-ferrous metal mines, inclined ore bodies are often mined using chutes to slide ore to lower drifts, improving ore output efficiency. Additionally, terrain conditions also affect the choice of transportation processes. In mountainous areas with complex terrain, special transportation methods such as cableways may be needed for ore transport.

The stability of the ore body and the nature of the surrounding rock determine the choice of support processes. For ore bodies and surrounding rocks with poor stability, such as some fractured rock masses or weak soil layers, enhanced support measures are needed to ensure safety during mining. In such cases, methods such as rock bolt support, cable bolt support, and shotcrete support can be used to enhance the stability of the ore body and surrounding rock. In a certain metal mine, due to poor stability of the ore body and surrounding rock, a combined support method of rock bolts and cable bolts was adopted, effectively controlling deformation and collapse of the surrounding rock and ensuring mining safety. For ore bodies and surrounding rocks with better stability, simpler support methods such as timber supports or metal frame supports can be used to reduce support costs. At the same time, support materials and structures should be reasonably selected based on the burial depth and ground pressure conditions of the ore body to meet support requirements. For example, in deep mining, due to high ground pressure, high-strength support materials and advanced support technologies are needed, such as high-strength rock bolts and cable bolts, as well as concrete lining support structures, to ensure the stability of mine workings.

The relationship between mine production capacity and service life

The scale, thickness, and mining technical conditions of the ore body have important impacts on the planning of mine production capacity. The larger the ore body scale and thickness, and the better the mining technical conditions, the higher the mine production capacity can be. In a large iron mine, with a huge ore body scale and stable thickness, advanced mining technologies and equipment were adopted to achieve large-scale mining, with an annual production capacity reaching millions of tons. At the same time, mining technical conditions also affect production capacity planning. If mining technology is advanced and equipment efficiency is high, such as using automated mining equipment and efficient transportation systems, mine production capacity can be increased. Conversely, if mining technology is outdated and equipment is aging, mine production capacity will be limited. Additionally, market demand and resource security levels must be considered to reasonably plan mine production capacity to ensure the mine's economic benefits and sustainable development.

The reserves, mining intensity, and resource recovery rate of the ore body determine the service life of the mine. The larger the ore body reserves, the lower the mining intensity, and the higher the resource recovery rate, the longer the service life of the mine. At a certain gold mine, through precise exploration and reasonable mining planning, the reserves of the ore body were accurately grasped. By adopting moderate mining intensity and advanced mining technology, the resource recovery rate was improved, thereby extending the service life of the mine. Conversely, if the mining intensity is too high and the resource recovery rate is low, the service life of the mine will be shortened. For example, some small mines, in pursuit of short-term benefits, overmine, causing serious resource waste and significantly shortening the service life of the mine. Therefore, during the mine development process, it is necessary to comprehensively consider various factors, reasonably determine the mining intensity and resource recovery rate to ensure the long-term stable production and sustainable development of the mine. At the same time, continuous strengthening of resource exploration and technological innovation is needed to find new resources and improve resource utilization efficiency, providing a guarantee for the sustainable development of the mine.

The ore body burial elements, as the core foundation of mining engineering, cover multiple key aspects such as strike, dip direction, dip angle, thickness, extension depth, burial depth, and various ore body shapes. These elements are interrelated and influence each other, jointly constructing the complex spatial form of the ore body underground. Accurately grasping these elements is of vital importance to all aspects of mining engineering.

In the selection of mining methods, the ore body burial elements play a decisive role. The burial depth and ore body scale determine whether to use open-pit mining or underground mining; the attitude and shape of the ore body further influence the specific mining method chosen. For example, stratiform deposits are suitable for longwall mining, while vein deposits require selecting methods such as segmented mining or stoping mining based on their characteristics.

The customization of mining processes is also closely related to the ore body burial elements. The ore extraction process needs to select appropriate methods based on the hardness, structure, and thickness of the ore body, such as drilling and blasting or mechanical excavation; the transportation process depends on the dip angle, thickness, and terrain conditions of the ore body, and can use various methods such as rail or trackless transport, electric shovels, or chutes; the support process is chosen based on the stability of the ore body and the nature of the surrounding rock, selecting different support methods such as rock bolt support, cable bolt support, or shotcrete support.

The production capacity and service life of the mine are also profoundly influenced by the ore body burial elements. The scale, thickness, and mining technical conditions of the ore body determine the production capacity of the mine, while the reserves, mining intensity, and resource recovery rate determine the service life of the mine. Reasonable planning of these elements is of great significance for achieving efficient, safe, and sustainable mining.

Previous Page