Well-plate mining steps: development, preparatory cutting, and extraction—reported by Black Diamond

I. Exploration

I. Exploration

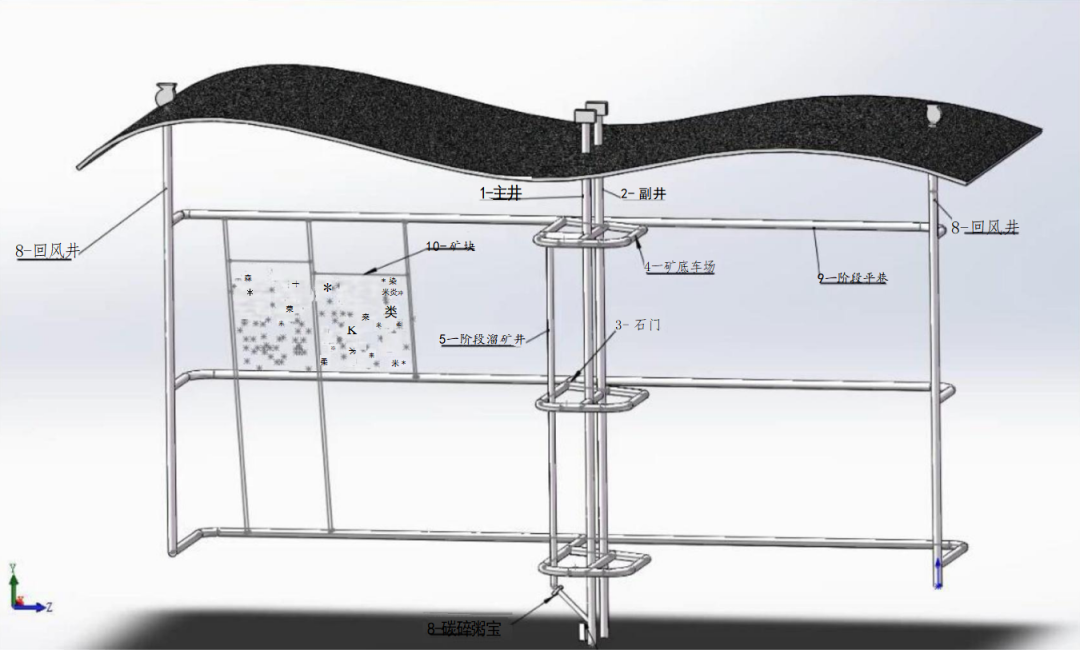

Excavation is the primary step in shaft mining, serving as the sturdy skeletal framework that supports the mine. It involves digging a series of shafts and tunnels from the surface down to reach the ore body—a critical process that lays the foundation for establishing seamless systems underground, including hoisting, transportation, ventilation, drainage, water supply, power distribution, compressed air (for动力), and backfilling—collectively known as the "Eight Major Systems." These eight systems are akin to the body's vital organs and circulatory network: each performs unique functions while working in harmony with the others, ensuring the smooth and efficient operation of underground mining activities.

Wellbore Engineering

Wellbore engineering is the core task in mine development. The main shaft, auxiliary shaft, and return air shaft—excavated vertically from the surface downward—are all critically important wellbores. Among these, the main shaft shoulders the vital responsibility of hoisting ore throughout the entire mining process, serving much like the aorta of the human body by continuously transporting the mined ore from underground to the surface. In large- and medium-sized mines, bucket skips are commonly used as the primary hoisting containers for coal, thanks to their ability to handle large volumes efficiently—making them perfectly suited for meeting the demands of large-scale extraction. On the other hand, the auxiliary shaft acts as an integrated "lifeline," responsible for transporting personnel, materials, and equipment. At the same time, it plays a crucial role in delivering fresh air deep into the mine, ensuring safe and smooth operations underground. Typically equipped with cage-type hoisting containers, the auxiliary shaft facilitates the convenient movement of both people and various supplies, enabling workers to enter and exit the mine safely and swiftly, while also guaranteeing that materials and equipment reach their intended work locations promptly. Lastly, the return air shaft has a more specialized function: it primarily removes stale, polluted air generated during underground operations, thereby maintaining optimal air quality and creating a healthy working environment for miners. Its importance cannot be overstated.

During the excavation process, each shaft must be precisely extended to the exact elevation specified in the design, accurately reaching the layer where the ore body is located. Throughout this process, connecting drifts and stone gates play a crucial role in linking the individual shafts together. These passages intertwine like the road network of a city, tightly connecting all the shafts and forming a comprehensive, multi-directional three-dimensional transportation system. This system ensures the efficient movement of personnel, materials, and air throughout the mine. For instance, when using a skip hoisting system in the main shaft, powerful winches and appropriately sized steel ropes are essential to guarantee stable and rapid ore lifting. Meanwhile, if the auxiliary shaft is equipped with multi-level cage systems, the number and dimensions of the cages must be carefully designed to meet diverse transportation requirements. Additionally, determining the appropriate diameter for the return air shaft is critical—this requires precise calculations based on the mine’s total airflow volume, ensuring optimal ventilation efficiency and enabling the timely removal of stale, contaminated air from underground.

The Eight Major Systems

Centered around the shaft, the eight major systems—including hoisting, transportation, ventilation, drainage, power supply, water supply, compressed air, and filling—cover a wide range of functions. These systems work in seamless coordination to ensure the smooth operation of the mine. The hoisting system, equipped with winches, steel cables, and other machinery, facilitates the vertical transport of ore and materials, serving as the vital link between underground operations and the surface. Meanwhile, the transportation system relies on channels such as the bottom-of-shaft car shed and stage-level drifts, combined with vehicles like mine cars and belt conveyors, to efficiently move ore from the working face down to the bottom of the shaft—and ultimately up to the surface via the main shaft—thereby guaranteeing that mined resources are swiftly transported from extraction sites to processing or storage areas.

The ventilation system is a critical component that ensures the safety and well-being of underground workers as well as maintains a healthy working environment. Powered by the main fan, it utilizes shafts and various ventilation structures to create a continuous airflow cycle: fresh air enters through intake shafts, while contaminated air is exhausted via return shafts. In practical operation, it’s essential to strategically install ventilation structures—such as dampers and air bridges—to effectively control airflow direction and regulate air volume distribution, ensuring that every work area receives an adequate supply of fresh air. Meanwhile, the drainage system centers around the pump station, utilizing underground drainage pipes to promptly convey wastewater from the mine to the surface, thereby preventing water accumulation that could jeopardize mining operations and safety. When designing the drainage system, careful consideration must be given to factors like the mine's water inflow rate and required pumping head, enabling the selection of appropriate pumps and pipelines to guarantee the system's reliability.

The power supply system draws cables from the surface substation and lays them through mine shafts to various underground power points, providing stable electrical support for all types of equipment and operations below ground. During the power supply process, it is crucial to ensure both the quality and safety of cable installation by incorporating essential protective devices to prevent faults such as leakage or short circuits. Meanwhile, the water supply system delivers production and domestic water underground, meeting critical needs like rock drilling, dust suppression, and drinking water for personnel. The compressed air system, on the other hand, supplies the necessary pneumatic tools and equipment underground with a reliable source of power air, ensuring their proper functioning. Finally, the filling system plays a vital role in managing mined-out areas by transporting filling materials into these zones, where they are used to provide support and stabilize the surrounding rock mass. This process helps control ground pressure, prevents surface subsidence, and ultimately ensures safe and sustainable mining operations. When selecting filling materials and designing the filling process, it’s essential to carefully weigh factors such as material performance, cost-effectiveness, and environmental impact—balancing these considerations to achieve optimal filling results while promoting the long-term sustainability of the mine.

II. Mining Preparation and Cutting

II. Mining Preparation and Cutting

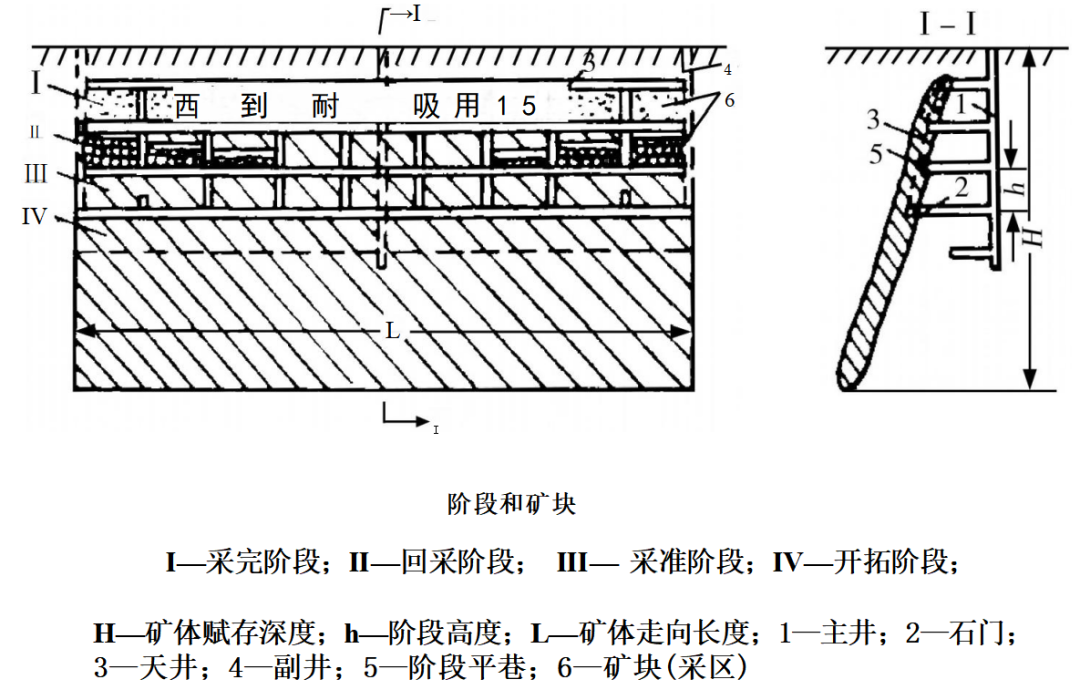

Mining cut-and-fill is a critical step that further refines and perfects the underground mining conditions after the basic framework of the mine shaft has been established during the development phase. It lays a solid foundation for the subsequent large-scale extraction operations—much like the meticulous preparatory work required before crafting a masterpiece—and directly influences both the efficiency and quality of the mining process.

Mining Preparation Engineering

In the ore bodies where development work has already been completed, the core task of preparatory mining engineering is to excavate a series of essential shaft and drifts, systematically dividing the ore body into independent, self-contained mining units—often organized as ore blocks or mining districts. Throughout this process, driving various types of underground roadways, such as district drifts, shafts, and connecting passageways, becomes critically important. Among these, shafts serve as vital vertical links connecting different stages; they not only provide essential pathways for personnel movement but also play a crucial role in ventilation, ensuring that fresh air circulates efficiently throughout all underground working areas, thereby creating a safe and secure environment for miners. For instance, in several large-scale metal mines, shafts are excavated at regular intervals, with their cross-sectional dimensions and support methods meticulously designed to meet both the needs of worker access and optimal airflow conditions.

The connecting drifts function like the "capillaries" beneath the mine, seamlessly linking all the individual development roadways into an integrated system that ensures the smooth operation of transportation, ventilation, and other critical processes. Meanwhile, the shafts excavated on both sides of the mining block resemble two "lifelines," providing safe and efficient access for workers to enter the block for operations. These shafts also allow a continuous supply of fresh air while simultaneously expelling stale, contaminated air from the area. And at the bottom, the transport level drifts act as the primary "artery" of the mine—directly connecting to the shaft yard at the bottom of the shaft. This design enables rapid removal of mined ore from the block, which is then swiftly transported down to the shaft yard before being hoisted to the surface via the main shaft, significantly boosting overall transportation efficiency.

The layout of mining preparation engineering is not fixed but closely tied to the specific mining method employed. Different mining techniques impose significantly varying requirements on preparation work. For instance, in the open-stope method, maintaining roof stability during extraction necessitates reserving mine pillars of adequate size and quantity to support the roof. This, in turn, demands that the layout of the preparation engineering carefully account for the placement and shape of these pillars, ensuring they can effectively fulfill their supporting role—while also guaranteeing that the arrangement of preparatory roadways does not compromise the stability of the pillars. Meanwhile, in the backfilling method, achieving efficient filling of mined-out areas requires the construction of a comprehensive backfill pipeline system. Consequently, the preparation engineering must be organized around this system, ensuring smooth delivery of backfill materials to the targeted zones. At the same time, the installation of the backfill pipelines must be meticulously planned to avoid disrupting the normal operation of other preparatory roadways and ongoing mining activities.

Cutting Engineering

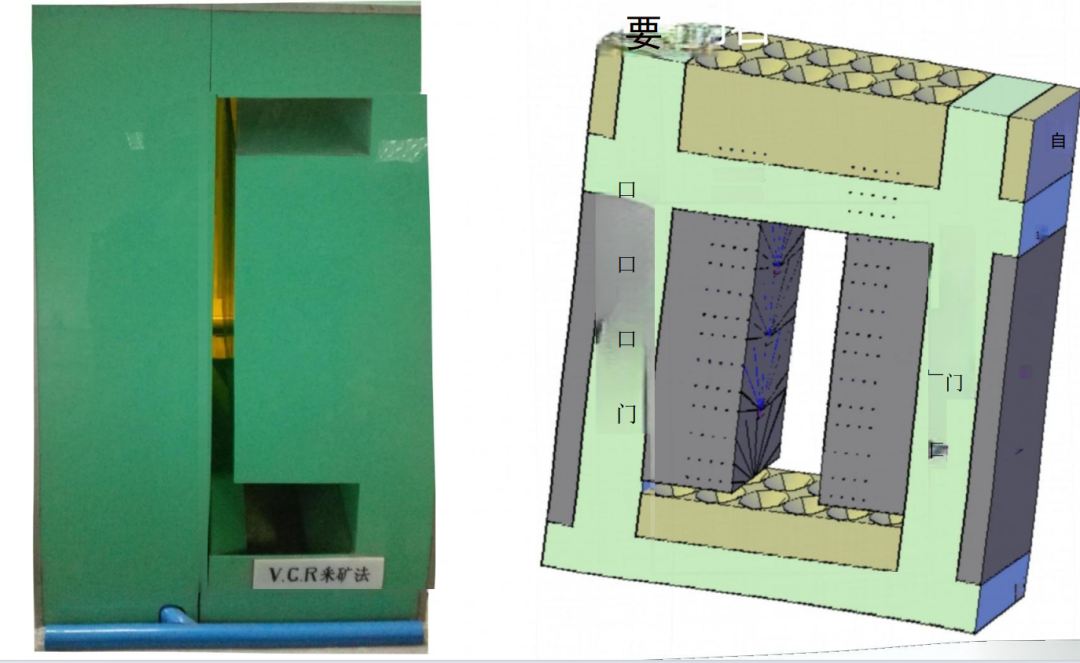

Within the mining unit where extraction work has been completed, cutting operations begin to play a critical role. These cutting tasks primarily involve key activities such as undercutting and excavating cutting slots, aimed at creating optimal free faces and sufficient blasting space for ore caving—essentially setting the stage for a spectacular "performance." Undercutting, an essential operation conducted at the bottom of the mineral block, involves driving drifts or employing blasting techniques to carve out a horizontal or inclined extraction space. This space serves as the "starting point" for ore caving, providing a solid foundation for subsequent mining activities. For instance, in certain non-ferrous metal mines, undercutting is often carried out using shallow-hole blasting, gradually expanding the bottom area according to design specifications to ensure that the dimensions and shape of the space fully meet the requirements of the upcoming ore-caving process.

Excavating the cutting slot is another critical step in the mining operation, as it involves creating a vertical or inclined groove within the ore body—typically through blasting or mechanical excavation. This groove serves to further enlarge the free surface area for ore fragmentation, thereby enhancing blasting efficiency and enabling smoother rock collapse. In the cut-and-fill stoping method without bottom pillars, the depth and width of the cutting slot directly and significantly influence the overall ore-caving performance. If the cutting slot is too shallow, the ore may not break down sufficiently during caving, leading to the formation of large blocks that hinder mining efficiency. Conversely, if the slot is too narrow, the range of ore collapse will be restricted, making it impossible to achieve the desired mining volume. Therefore, when designing and constructing the cutting slot, it’s essential to perform precise calculations and meticulous construction tailored to the actual conditions, such as the ore body’s thickness and the hardness of the mineral, ensuring that all parameters of the cutting slot meet the required specifications.

3. Mining Retracement

3. Mining Retracement

Mining extraction is the core stage of underground mining operations, involving extensive mining activities carried out within the extraction units after preparatory cutting and development work has been completed. This process encompasses several closely interconnected procedures—such as rock drilling, blasting, ventilation, ore transportation, and ground pressure management—each serving as a vital link in the chain that collectively facilitates the movement of ore from the underground deposit to the surface. Ultimately, these processes directly determine the efficiency, quality, and economic viability of the mine's overall operations.

Mining Operation Step

Rock breaking is the primary task in mining operations, with its core process involving the synergistic combination of rock drilling and blasting to efficiently separate ore from the mineral body and reduce it into fragments of an appropriate size for subsequent processing. In this process, the selection and operation of rock-drilling equipment are critical. Commonly used rock-drilling tools include rock drills and drilling rigs, which precisely drill blast holes at the working face according to the specific conditions of the ore body and the requirements of the mining method. For instance, when extracting hard metallic ores, high-power, precision-drilling hydraulic rock drills are often preferred, as they can maintain stable performance even under challenging geological conditions, ensuring that the blast holes meet the design specifications.

Parameters such as blast hole depth, spacing, and angle must be carefully designed and adjusted based on the orebody’s structural characteristics, the hardness of the ore, and the mining method employed. For medium-to-deep-hole blasting, the typical depth of blast holes is controlled within the range of 5 to 15 meters—this depth ensures both an effective blast radius and optimal efficiency for drilling and blasting operations. Determining the appropriate blast hole spacing requires a comprehensive consideration of ore fragmentation performance and blasting costs; generally speaking, well-chosen spacing allows for uniform distribution of explosive energy, ensuring thorough ore breakage while minimizing excessive fragmentation that could lead to resource wastage. Additionally, the angle setting cannot be overlooked, as it directly influences the direction in which blasted ore is thrown and the resulting pile formation, thereby impacting subsequent ore-handling processes.

After the blast holes have been drilled, charging and blasting become the critical steps in rock fragmentation. The charging process must be carried out strictly according to design specifications, ensuring uniform distribution of explosives within the holes and precise dosage. Different types of explosives possess unique performance characteristics, so it’s essential to select the appropriate one based on the ore properties and blasting requirements. For instance, for harder ores, high-powered emulsified explosives are typically chosen to guarantee efficient rock breakage; meanwhile, in areas more sensitive to blast vibrations, lower-velocity, low-power explosives are preferred to minimize disturbance to the surrounding rock mass.

To minimize the damage caused by blasting vibrations to surrounding rock and enhance ore recovery rates, millisecond-delayed blasting technology has been widely adopted. This technique precisely controls the detonation timing of individual blast holes, allowing the explosive energy to be released at different intervals, thereby enabling fine-tuned management of the blasting process. For instance, after implementing millisecond-delayed blasting in a large-scale metal mine, blast vibration intensity was significantly reduced, effectively safeguarding the stability of the surrounding rock, while ore recovery rates improved by more than 10%.

Ventilation and Safety

Ventilation is a critical step in ensuring the safety of personnel and maintaining high-quality working conditions during the mining process. After blasting operations are completed, the mining area becomes filled with significant amounts of blast fumes and dust—harmful substances that contain toxic gases such as carbon monoxide and nitrogen dioxide, along with fine particulate matter. If these harmful materials are not promptly removed, they can pose a serious threat to the health of workers, potentially leading to occupational diseases like poisoning or pneumoconiosis.

To effectively remove blasting fumes and dust while introducing fresh air, mines are typically equipped with well-designed mechanical ventilation systems. These systems primarily consist of equipment such as air ducts and fans. Powered by the robust force generated by the fans, they continuously deliver fresh air to every corner of the mining area, while simultaneously exhausting stale, contaminated air—laden with harmful substances—back through the air ducts. The airflow rate and pressure of the ventilation system must be precisely adjusted based on factors like the size of the mining area, the number of workers present, and the scale of blasting activities. For instance, in a large-scale mining operation with extensive working areas and a high workforce, powerful, high-capacity fans are essential to ensure adequate airflow coverage throughout the entire site, thereby meeting both workers' breathing needs and the requirement for diluting hazardous gases.

During the ventilation process, it is also necessary to utilize various ventilation structures to effectively control the direction of airflow and distribute air volumes appropriately. Ventilation structures such as wind bridges and air doors help guide airflow along predetermined paths, preventing short-circuiting or dead zones, and ensuring that each working area receives an adequate supply of fresh air. To monitor air quality in the mining face in real time, mines are equipped with specialized equipment like gas detectors and dust monitors. These devices continuously track the concentrations of harmful gases and dust levels within the mine face, and if readings exceed safe thresholds, they immediately trigger alarms, alerting workers to take immediate action—such as enhancing ventilation or donning protective gear—to safeguard their safety and well-being.

Mineral Transportation

Ore transportation is the critical process that ensures smoothly moving collapsed ore from the mining face and lifting it to the surface, directly impacting the mine's production efficiency and economic benefits. In this process, it is essential to select appropriate transportation equipment and methods based on factors such as the dip angle of the ore body, the characteristics of the ore, and the specific mining techniques employed.

For inclined ore bodies, self-gravity transportation is a commonly used and highly efficient method of moving materials. Due to the natural dip angle of the ore body, the ore can naturally slide down along designated channels under the influence of gravity, enabling seamless transfer from the mining face to the transport roadway. This approach not only reduces equipment investment and energy consumption but also significantly enhances transportation efficiency. For instance, in the extraction of steeply inclined ore bodies, setting up chutes at the bottom of the mining face allows the ore to flow directly into the chutes by gravity, where it can then be discharged via chute-bottom discharge devices into transport vehicles—dramatically boosting the speed of ore movement.

For thick and large ore bodies, the combination of loaders paired with belt conveyors is more commonly used. Loaders boast powerful loading capacity, enabling them to quickly load fragmented ore onto belt conveyors. Meanwhile, belt conveyors offer continuous transportation, efficiently delivering the ore to the designated location. This combined approach fully leverages the strengths of both equipment types, making it ideal for large-scale mining operations. In practice, loaders operate flexibly within the mining area, scooping up the ore and depositing it into the belt conveyor's receiving hopper. The belt conveyor then transports the ore steadily along pre-installed tracks, ultimately conveying it to the bottom-of-shaft car shed—and from there, via the main shaft, the ore is hoisted back to the surface.

Throughout the entire ore transportation process, each transport stage must work closely together to create an efficient relay system. From the mining face to the stage-level transport drifts, then to the bottom-of-shaft car shed, and finally via the main shaft for lifting to the surface—every step requires careful planning and management to ensure smooth ore flow, preventing bottlenecks, delays, or other disruptions, thereby enhancing the mine's overall production efficiency.

Ground Pressure Management

Ground pressure management is a critical measure in mining operations to ensure the safety and stability of working faces and goaf areas. It directly impacts the mine's safe production and sustainable development. As ore extraction continues, the stress equilibrium around the working face and goaf zones is disrupted, potentially leading to safety hazards such as roof collapses and rib spalling. Therefore, effective ground pressure management techniques must be implemented to control ground pressures and safeguard operational safety.

In terms of mine support, commonly used methods include bolt support, cable support, and metal support systems. Bolt support works by anchoring bolts into the rock mass, leveraging their gripping force to prevent deformation and sliding of the surrounding rock. Cable support, on the other hand, is particularly suitable for areas with poor rock stability, as it uses the powerful tensile strength of cables to significantly enhance overall structural integrity. Meanwhile, metal support systems are designed to directly bear the pressure exerted by the rock mass, providing robust reinforcement for the mining area. In some mines with complex geological conditions, a combination of these support methods may be employed to ensure optimal results. For instance, at a particular mine site, deep bolting and cabling were first implemented to strengthen the internal stability of the rock mass. Subsequently, metal supports were installed across the mine’s surface, further boosting the overall support capacity and effectively mitigating risks such as roof collapses and rib spalling incidents.

For the treatment of mined-out areas, depending on the mine's geological conditions and mining methods, options such as backfilling, caving, or sealing can be selected. Backfilling involves filling the mined-out areas with backfill materials (such as tailings, cementitious materials, etc.) to create a stable backfill body that supports the surrounding rock and controls ground pressure. This method not only effectively manages ground pressure in mined-out areas but also reduces the risk of surface subsidence, enabling environmentally friendly mining operations. For instance, in some metal mines, the tailings-cemented backfilling method is employed: treated tailings are mixed with cementitious materials like cement and then transported via pipelines directly into the mined-out zones, forming a backfill body with sufficient strength. This approach not only addresses the issue of tailings disposal but also ensures the long-term stability of the mined-out areas. Caving, on the other hand, involves allowing the surrounding rock to collapse naturally into the voids, thereby relieving stress concentrations around the mining area and effectively controlling ground pressure. Sealing, meanwhile, is particularly suitable for smaller mined-out areas or those posing minimal impact on the surrounding environment. It involves constructing barriers or other containment structures to isolate the mined-out zone from the outside world, preventing unauthorized access and mitigating the risk of ground-pressure-related accidents.