The Content and Role of Mining Engineering Drawings — Heijinggang Broadcast

In the complex and systematic engineering process of mine exploitation, mining engineering drawings are indispensable and crucial technical documents. Among them, the mining engineering plan view—serving as a core component—is directly created based on comprehensive data from geology, surveying, and mining operations, effectively acting as the mine's "digital blueprint" that precisely conveys all critical information about the underground space. This article will delve into both the content and functional significance of this vital technical document.

A Rich and Diverse Content System

A Three-Dimensional Presentation of Geological and Structural Information

The mining engineering drawings comprehensively depict the detailed conditions of coal seam occurrence, including key parameters such as coal seam thickness, dip angle, and strike—data that form the foundation for assessing the economic value of coal seam extraction. At the same time, the drawings clearly mark major geological structures, such as faults, folds, and collapse columns. Accurately portraying these geological features provides critical predictive insights into potential challenges miners may encounter during the extraction process, enabling operators to prepare in advance. For instance, when a fault is identified, miners can adjust their extraction plan accordingly based on the fault’s location and scale shown in the diagram, thereby preventing disruptions to both mining progress and safety caused by geological complexities.

Precise positioning of tunnel and facility layouts

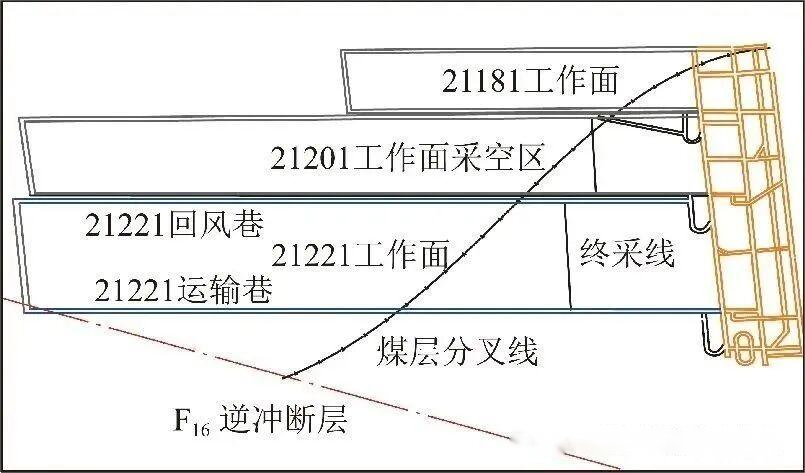

The layout of major underground chambers and mining roadways is clearly visible at a glance in the diagram. The main chambers include substations, pump rooms, refuge chambers, and more—critical components that ensure the smooth operation of the mine. Their rational planning directly impacts the overall productivity and safety of the entire mining operation. Meanwhile, the mining roadways serve as the "lifelines" of the mine, comprising transportation tunnels, return airways, working face passages, and other key routes. The diagram meticulously marks the length, width, height of each roadway, as well as their interconnections. Armed with this information, miners can easily grasp the spatial arrangement beneath the surface, facilitating efficient construction management and resource allocation. Additionally, the diagram visually conveys the progress of ongoing projects, enabling real-time monitoring of the advancement rate and completion status at each mining face—and providing crucial data for adjusting production schedules accordingly.

Dynamic Display of Project Progress and Spatial Relationships

The interrelationships among working faces are intuitively depicted on the mining engineering drawings. The positional relationships, distances, and degrees of mutual influence between different coal mining and excavation working faces are clearly visible. This helps in rationally planning the sequence of operations across various working faces, thereby preventing safety incidents caused by interference among them. Meanwhile, the diagram also highlights critical components such as the development system and the ventilation and transportation systems. The development system includes essential infrastructure for mine operations, such as shafts, underground terminal stations, and main transport roadways. In contrast, the ventilation and transportation systems ensure proper airflow underground and efficient material handling—both of which are vital to maintaining safe and stable mining operations. By providing detailed depictions of these systems, the drawings enable mining personnel to gain a clearer understanding of the mine's overall layout and operational mechanisms.

An indispensable and important role

Providing a scientific basis for production planning

Mining is a long-term and complex process that requires the development of detailed production plans. Mining engineering drawings serve as accurate foundational data, providing a scientific basis for tasks such as mine exploration planning, mining area division, and working face layout. By analyzing the geological conditions, tunnel layouts, and project progress depicted in these drawings, it becomes possible to rationally determine the mining sequence, select appropriate extraction methods, and choose optimal equipment—ensuring that mining operations proceed efficiently and systematically. For instance, when planning a new mining area, engineers can leverage the coal seam distribution and geological structure shown in the drawings to identify the most suitable location and design the best extraction strategy, thereby enhancing both resource recovery rates and operational efficiency.

The crucial safeguard for ensuring safe production

Ensuring safe production is the top priority in mining operations. Mine excavation maps enable workers to proactively identify underground geological risks and potential hazard zones—such as fault zones and areas where gas tends to accumulate—allowing them to implement appropriate safety measures. At the same time, the maps provide clear information on tunnel layouts and ventilation/transportation systems, which proves invaluable for swiftly developing rescue plans in the event of an accident, thereby enhancing emergency response capabilities. For instance, during incidents like fires or gas explosions, rescue teams can quickly pinpoint the optimal evacuation routes and ventilation strategies by referring to the map’s detailed depiction of tunnel locations and airflow conditions, ultimately minimizing both human casualties and property damage.

The key tool for enabling efficient resource utilization

Rationally developing and utilizing mineral resources is a key objective for mining enterprises. Mining engineering maps, by accurately depicting the occurrence of coal seams and geological structures, provide a solid foundation for estimating resource reserves and optimizing extraction plans. During the mining process, these maps enable timely adjustments to extraction techniques, thereby enhancing resource recovery rates and minimizing waste. Additionally, the dynamic visualization of the interrelationships among working faces and the progress of ongoing projects helps ensure that mining schedules are planned efficiently, preventing both over-extraction and under-extraction—both of which could compromise the sustainable and rational use of resources.

An important medium for facilitating technical communication and management

In the field of mining operations, technical exchange and management are crucial tools for enhancing productivity and improving operational efficiency. Mining engineering drawings, as a universal technical language, enable personnel from different departments and specialized fields to quickly grasp the actual conditions of the mine, facilitating seamless communication and collaboration. Meanwhile, for the management team of mining enterprises, these drawings serve as an essential foundation for production management and decision-making. By analyzing the information depicted in the drawings, managers can promptly identify issues arising during the production process and implement appropriate management strategies, ultimately elevating the overall efficiency and effectiveness of the company.