Analysis of the Core Concepts Behind the Flat Shaft Development Method — Heijinggang Broadcast

Analysis of the Core Concepts of the Adit Development Method

Definition and Core Components of the Level-Entry Development Method

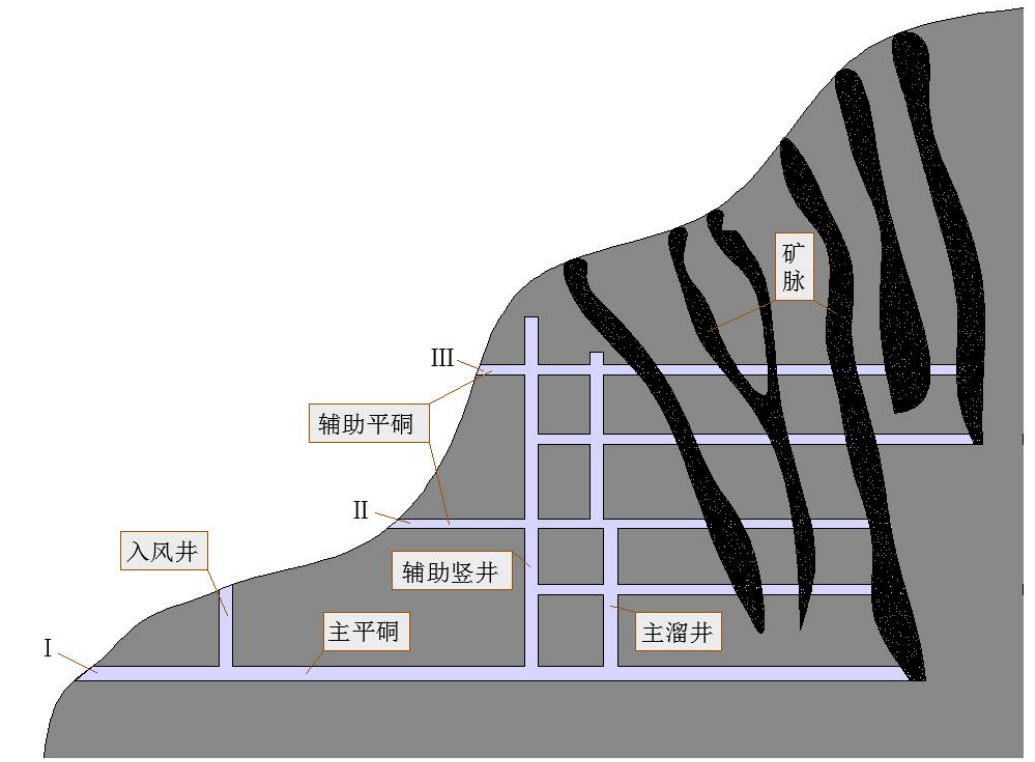

The flat adit development method, a unique and crucial technique in the field of mine exploitation, refers to an approach where horizontal tunnels (flat adits) are driven directly from the surface into the ore body. This method ingeniously leverages natural terrain conditions, proving particularly effective for mining operations in mountainous regions—and has thus become the preferred solution for many mining enterprises.

In the system of the adit development method, the adit serves as its core component. Depending on their functions, adits are primarily categorized into two types: main adits and stage adits. The main adit plays a central role in the overall operation of the mine, acting like the aorta in the human body—it is the critical hub of the entire mining system. It continuously transports ore extracted from the mineral deposit to the surface, and its capacity and stability directly influence the mine's production efficiency and economic profitability. On the other hand, stage adits support each specific mining phase, functioning much like the network of blood vessels distributed throughout the body. These adits connect individual stages to the main adit, enabling not only the transportation of ore but also handling waste rock, personnel, materials, and equipment. Together, they form a sophisticated, multi-stage, three-dimensional transportation network that ensures the smooth progression of mining operations.

Technological Advantages and Engineering Characteristics

The flat adit development method boasts numerous significant technical advantages, making it an efficient and cost-effective approach under specific geological conditions. Among these, leveraging the natural elevation difference of the terrain to enable gravity-fed ore discharge is one of its most distinctive technical features. By carefully designing the adit’s slope and the chute system, ore can flow downward automatically under the force of gravity—eliminating the need for additional power-driven equipment to lift it. This not only dramatically reduces energy consumption during transportation but also enhances overall efficiency while cutting down on operational costs.

In terms of engineering characteristics, the slope of adit roadways is typically controlled within the range of 3‰ to 7‰. This specific slope range is not arbitrary—it has been carefully determined after thorough consideration. On one hand, such a gradient ensures that ore can flow smoothly downhill under its own weight. On the other hand, it also optimizes both drainage and ventilation efficiency. Regarding drainage, the appropriate slope allows underground water to naturally flow toward the sump at the bottom of the shaft, making it easier to collect and discharge the water efficiently. As for ventilation, a well-chosen slope helps establish effective airflow channels, ensuring that fresh air can readily reach all working areas underground while simultaneously expelling stale, contaminated air to the surface. This setup creates a safe and comfortable working environment for miners and other personnel operating in the mine.

Additionally, the construction process of the adit development method is relatively simple, which is one of the key reasons behind its widespread application. Compared to other methods such as shaft and inclined shaft development, adit development does not require complex vertical or inclined excavation during construction, making it less challenging to execute and offering relatively favorable working conditions. As a result, construction speed is significantly accelerated, and the infrastructure-building period is markedly shortened, enabling mines to start production in a much shorter timeframe and achieve substantial economic benefits. Moreover, thanks to the straightforward construction process, fewer specialized equipment and manpower are needed, thereby reducing initial investment costs. Typically, the upfront capital required for adit development is 30% to 50% lower than that for shaft or inclined shaft development. This makes it especially appealing to small- and medium-sized mines facing financial constraints, allowing them to quickly ramp up operations and reap economic returns even with limited funding.

Main Layout Plan and Engineering Selection for the Flat Shaft Development Method

Vertical orebody dip-and-dip adit development method

When the ore vein runs in the opposite direction to the slope's inclination, the sub-level drift development method becomes a highly effective choice. This approach works best when the rock beneath the ore body exhibits excellent stability, providing a solid foundation for both the initial excavation of the drift and its long-term operation. In practice, the drift is first driven into the surrounding rock beneath the ore body, cutting vertically through the vein itself. This creates a network of interconnected drifts—linking the main drift with the stage-level drifts. To ensure efficient ore transportation, auxiliary blind shafts and main decline shafts are also constructed. As a result, ore extracted from the upper stages can naturally flow downward by gravity, sliding smoothly along the decline shafts directly into the main drift level, where it is then transported to the surface via the main drift system.

The sublevel adit development method boasts unique advantages, the most prominent of which is its ability to simultaneously conduct supplementary exploration of mineral veins as the adit traverses through them. This process essentially serves as a comprehensive "health check" for the ore body, enabling miners to gather more detailed information about the veins—such as variations in thickness and the distribution of ore grades—thereby providing a more accurate geological foundation for subsequent mining operations and effectively mitigating geological risks during extraction. In China, this development approach has been widely adopted in the mining of small- to medium-sized vein-type deposits, particularly in the extraction of metallic ores like tungsten and tin, where its application rate exceeds 60%. As a result, it has become an essential tool for these mines to achieve efficient and productive operations.

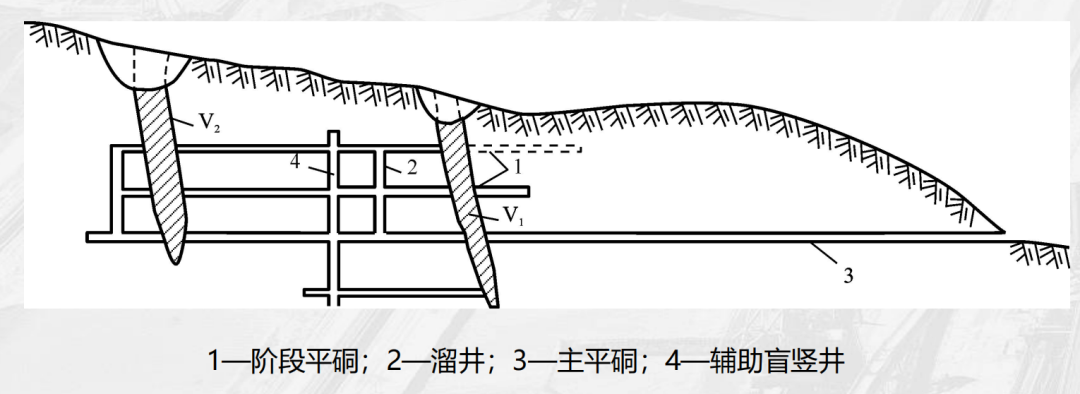

Vertical orebody dip-direction adit development method

When the ore vein aligns with the slope of the hillside, the overlying strata are stable, and suitable conditions exist for industrial site layout, the vertical adit development method along the strike of the mineral body becomes a viable option. In this approach, an adit is driven into the upper side of the ore body, penetrates through the vein, and then stage adits are arranged parallel to the vein’s strike. To ensure safe and efficient underground operations, an independent ventilation system must also be installed, guaranteeing fresh air circulation underground. Additionally, waste rock chutes should be set up to promptly remove the waste rock generated during mining.

Typical engineering structures include the stage adit (1), chute shaft (2), main adit (3), and auxiliary blind shaft (4), which work together to create a "top-rock intrusion—segmented transportation" model. In practical applications, it is essential to strictly control the conditions under which this method can be effectively implemented; among these, the degree of weathering in the overlying rock strata is a critical factor. If the overlying rock is severely weathered, its stability will be significantly compromised, not only increasing the cost and complexity of adit support but also potentially jeopardizing the safety of mining operations. Therefore, before adopting this development approach, a comprehensive and meticulous assessment of the rock’s weathering condition must be conducted, followed by the implementation of appropriate reinforcement measures to ensure the adit remains safe and stable. This method is particularly well-suited for ore deposits such as quartz-vein-type gold mines, where high demands are placed on ventilation and drainage. By fully leveraging its advantages in these areas, the method can effectively support efficient mining operations while maintaining optimal environmental conditions within the mine.

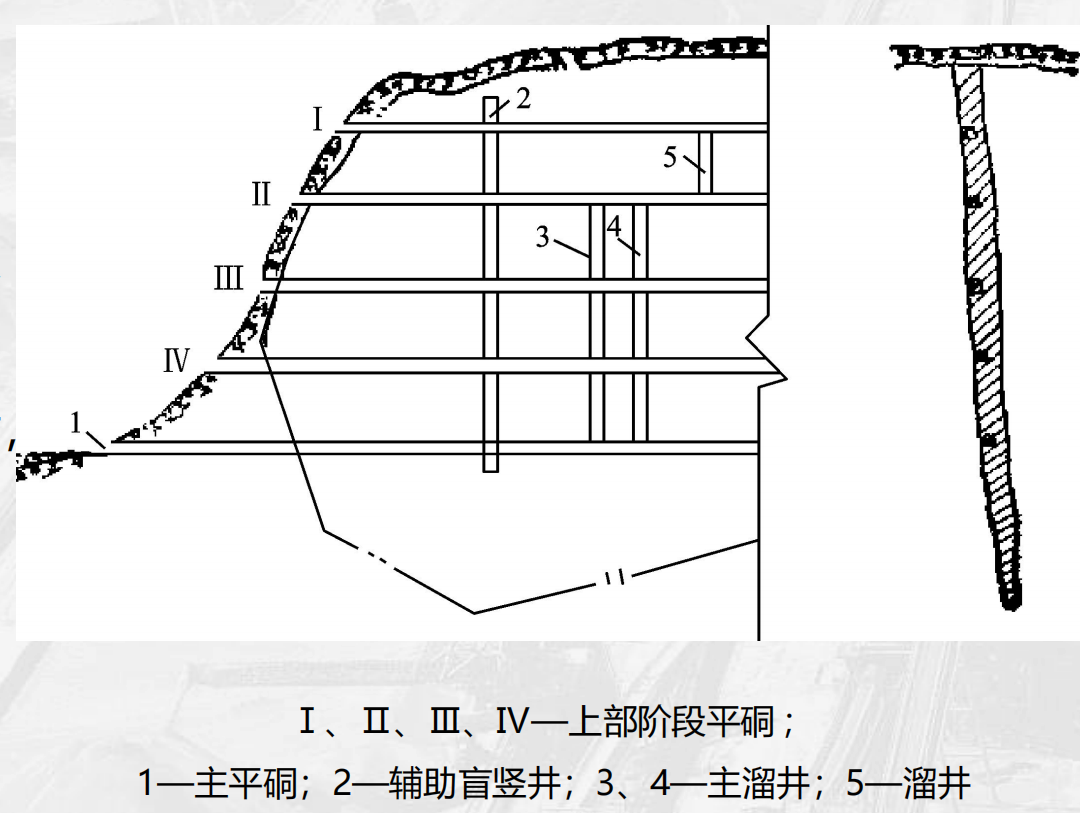

Along-Mine-Axis Adit Development Method

The flat adit development method, aligned with the orebody trend, is suitable for situations where mineral veins outcrop along the slopes of hillsides. It requires that the strike length of the vein exceeds 300 meters, the orebody thickness be no more than 5 meters, and the ore itself exhibit good stability. In this mining approach, the flat adit is driven parallel to the vein’s strike; when the orebody is relatively thin, the adit is typically laid directly within the vein. This strategy offers the advantage of simultaneously recovering off-vein ore during the initial construction phase—though such ore may have lower grades, its rational extraction and utilization can offset 15% to 20% of the capital investment required for infrastructure, thereby significantly reducing the overall cost of mine development.

However, if the ore vein is relatively thick or the surrounding rock is fractured, the adit must be shifted into the lower wall rock to ensure the stability of the roadway. The greatest advantage of the adit development method along the ore body trend lies in its ability to enable "simultaneous development and mining." This highly efficient operational approach can reduce the project commissioning period by 3 to 6 months, allowing the mine to ramp up production more quickly and realize economic benefits sooner. Therefore, this method is particularly well-suited for the efficient development of steeply inclined, thin ore veins, fully leveraging its strengths in shortening the commissioning timeline and enhancing mining efficiency—ultimately delivering significant economic advantages to mining enterprises.

Comparison of Advantages and Disadvantages of the Adit Development Method and Directions for Optimization

Core Advantages

The flat adit development method has proven to be remarkably cost-effective in mining operations, making it the preferred choice for many mining enterprises. In terms of infrastructure costs, flat adit development offers a clear advantage over shaft development. For instance, at a certain metal mine, the unit-length excavation cost using the flat adit method is approximately 40% lower than that of shaft development—primarily because adit construction is relatively simple, eliminating the need for complex hoisting equipment and intricate shaft-support structures. Additionally, annual maintenance costs for adits are more than 20% lower than those for shafts, enabling mines to significantly reduce expenses over the long term. Moreover, the flat adit method excels in construction speed as well, with excavation rates about 25% faster than those of shafts or inclined shafts. This accelerated pace allows mines to complete their infrastructure projects in a shorter timeframe, enabling earlier entry into the production phase—and ultimately saving substantial time and capital costs for the company, thereby greatly enhancing the overall economic efficiency of the mine operation.

The flat adit development method also boasts a notable feature of functional integration. In terms of ventilation, the method leverages natural air pressure to achieve effective airflow, naturally creating negative pressure that ensures fresh air flows smoothly into all underground working areas, while stale air is efficiently expelled to the surface. This not only reduces the initial investment and operational costs associated with ventilation equipment but also enhances the reliability and stability of the ventilation system. Regarding drainage, the flat adit approach typically employs gravity-based drainage, resulting in a straightforward and cost-effective system that requires no additional pumping equipment or power sources—significantly cutting down on drainage expenses. Moreover, in multi-stage mining operations, the flat adit method enables balanced production capacity across all stages. A single adit can handle daily transportation volumes ranging from 500 to 1,000 tons, easily meeting the demands of large-scale mining operations and providing robust support for the mine’s efficient and productive day-to-day activities.

The flat adit development method also excels in terms of geological adaptability. During the excavation of flat adits, it becomes possible to conduct supplementary exploration of the ore body, gathering more detailed geological information such as the ore body's strike, dip angle, and thickness. This is crucial for rationally planning mining operations and enhancing ore recovery rates. Particularly in small- to medium-sized mines with complex geological conditions, the flat adit method can better accommodate variations in the ore body, allowing for flexible adjustments to the mining plan and ensuring the sustainable development of the mine.

Technological Limitations and Countermeasures

The adit development method has certain limitations in terms of length. When the adit exceeds 1,500 meters in length, ventilation resistance significantly increases, which can adversely affect underground ventilation efficiency, leading to deteriorated air quality and posing risks to the health and safety of workers. To address this issue, measures such as installing additional local fans or constructing through-type ventilation shafts can be implemented. Local fans can provide extra ventilation power in areas with high resistance, ensuring that fresh air is delivered smoothly. Meanwhile, through-type ventilation shafts can create additional airflow pathways, reducing ventilation resistance and enhancing overall ventilation efficiency. Additionally, optimizing tunnel curvature and cross-sectional dimensions using 3D modeling techniques can effectively minimize ventilation resistance and boost ventilation performance. Based on practical engineering experience, the optimized tunnels can achieve a 15%–20% reduction in ventilation resistance, dramatically improving underground ventilation conditions.

Ground pressure management is a critical issue in the adit development method, especially in the case of intraductal adits. Since adits are located deep within the orebody, ground pressure significantly impacts their stability. To ensure the safety of the adits, it’s essential to leave behind a 3-to-5-meter safety pillar that helps support the surrounding rock mass under pressure. Additionally, combining anchor, mesh, and shotcrete support techniques can enhance the stability of the adit’s surrounding rock through the synergistic action of these elements. In areas where the surrounding rock is particularly unstable, prioritizing the use of lower-dip rock roadways is recommended to prevent ground pressure from compromising the adit’s integrity. By implementing these ground pressure management strategies, the stability of adits can be effectively improved, thereby ensuring safe and uninterrupted mining operations.

In terms of drainage, water accumulation in long-distance tunnels poses a significant challenge for the adit development method. To address this issue, an automatic drainage pumping station equipped with a water-level monitoring system can be installed at the lowest point of the adit. When the water level reaches the preset threshold, the pumping station will automatically activate, efficiently removing the accumulated water. Additionally, using large-diameter drainage pipes and high-performance drainage pumps can further enhance the system's capacity, ensuring that no water remains inside the adit. By implementing these optimized drainage measures, the problem of water buildup in long tunnels can be effectively resolved, thereby guaranteeing the smooth execution of the adit development method. 4

Surface Adit Development Method: Application Conditions and Engineering Decision Factors

Geological and Topographical Conditions

The occurrence conditions of the ore body are one of the key factors determining whether the adit development method should be adopted. When more than 80% of the ore body lies above ground level and its burial depth is less than 200 meters, the adit method offers significant advantages. This is because, under these circumstances, adits can directly access the ore body, eliminating unnecessary hoisting and transportation steps, thereby substantially reducing mining costs. Additionally, if the ore body has a strike length exceeding 200 meters and an inclination angle between 30° and 90°, it further creates favorable conditions for implementing the adit method. A longer strike length ensures that sufficient ore remains available for extraction during adit excavation, while the appropriate dip angle facilitates the natural gravity flow of ore, enhancing transportation efficiency.

The adit development method has certain requirements for terrain conditions, with mountainous or hilly areas being the most ideal. In these regions, slope gradients typically range from 20° to 45°—a gradient that not only facilitates adit excavation but also leverages the natural elevation difference to enable gravity-fed transportation of ore. At the adit exit, a level industrial site is essential for accommodating facilities such as concentrators, warehouses, and maintenance workshops. The area of the industrial site should be carefully planned based on the mine's production scale and process flow; generally speaking, small mines require an industrial site no smaller than 5,000 square meters, medium-sized mines need at least 10,000 square meters, while large-scale mines will demand even more space. Moreover, the elevation of the adit exit must exceed the local once-in-a-century flood level by at least 3 meters, ensuring that mine facilities and personnel remain safe during flooding events. This underscores the importance of conducting thorough surveys and analyses of local hydrological data during the mine-site selection and design phases, enabling accurate determination of the critical flood level.

Key Factors in Engineering Decision-Making

The stability of the ore body is one of the key factors that must be carefully considered in the adit development method, as it directly affects both the safety and service life of the adit. Determining the rock mass strength factor (f-value) through rock mechanics tests is an important approach for assessing ore body stability. For intrabed adits, which are located directly within the ore body and thus experience significant influence from the surrounding ground pressure, the rock mass strength factor must meet f ≥ 6 to ensure stability during both excavation and operation. In contrast, for down-dip adits—situated in the rocks beneath the ore body—their exposure to ground pressure is relatively lower; therefore, the required strength factor can be slightly relaxed to f ≥ 4. In practical engineering applications, it is also essential to evaluate the overall stability of the ore body by considering specific site conditions, such as ore body thickness, dip angle, and the degree of joint development, while implementing appropriate support measures to guarantee adit safety.

In engineering decisions regarding the adit development method, economic factors are a crucial consideration. When the ratio of adit length to orebody thickness is less than 30:1, placing the adit within the vein typically proves more economical. This is because, under these conditions, an in-vein adit can minimize rock excavation volume and reduce capital construction costs—while also allowing for the simultaneous extraction of some ore during the mining process, thereby boosting the mine's overall economic efficiency. However, when this ratio exceeds 30:1, an adit excavated in the footwall rock becomes the superior choice. As the adit length increases, the maintenance and ventilation costs associated with an in-vein adit rise significantly. In contrast, although excavating an adit in the footwall rock requires a larger initial investment, it ultimately helps minimize ore loss and dilution over time, leading to lower operational costs and enhanced long-term profitability for the mine.

As environmental awareness continues to grow, the environmental protection requirements in mining operations are becoming increasingly stringent. In the adit development method, the adit exit serves as the critical connection point between the mine and the outside world, making it essential to rigorously implement environmental protection measures. According to the environmental protection provisions outlined in the "Safety Code for Metal and Non-Metallic Mines" (GB 16423 - 2020), an impermeable layer must be installed at the adit exit to prevent harmful substances from waste rock from seeping into the ground, thereby safeguarding soil and groundwater from contamination. Additionally, dust collection systems should be equipped to effectively capture and treat dust generated during mining operations, minimizing its impact on air quality. In practical projects, further environmental measures should also be adopted, such as greening the areas surrounding the mine and carefully planning the drainage system, to ensure the harmonious coexistence of mining activities and environmental protection.

Typical Engineering Cases and Technological Innovations

Application Practice of a Quartz Vein-Type Gold Deposit

In a certain quartz-vein-type gold mining project, the ore body exhibits unique geological features. Its dip angle reaches 65°, a steep inclination that makes gravitational forces on the ore particularly critical during the mining process. The deposit lies at a relatively shallow depth of 150 meters, providing favorable conditions for implementing the adit development method. Following detailed geological surveys and engineering analyses, the mine has decided to adopt the along-strike adit development technique, which fully leverages the topographic advantages of the ore body’s lateral exposure along the hillside, enabling efficient extraction.

In the specific engineering layout, the stage adits were carefully placed within the ore veins. This arrangement not only demonstrated significant advantages during the construction phase but also delivered substantial economic benefits for the mine's long-term operations. During the construction period, through well-planned mining strategies, the mine successfully recovered 50,000 tons of off-vein ore. Although these off-vein ores had relatively lower grades, they still generated meaningful economic returns after being processed efficiently via advanced beneficiation techniques. These earnings helped offset part of the initial capital investment, easing the financial burden on the mine. Additionally, the mine achieved profitability six months ahead of schedule—a result directly attributable to the efficiency of the along-strike adit development method, which enabled the mine to accelerate its transition into the production phase and swiftly convert its investments into tangible economic gains.

To ensure the safety and stability of adit development, the mine has introduced advanced laser scanning technology. This technology enables dynamic monitoring of roadway deformation, using high-precision laser measurements to capture real-time data on any shifts or distortions in the tunnels. By analyzing this data, the mine can promptly identify potential safety risks and implement appropriate support measures. Practice has shown that adopting laser scanning technology has reduced support costs by 18%. This improvement stems not only from the ability to detect and address issues early, preventing costly large-scale repairs caused by excessive roadway deformation, but also from the capacity to design tailored support solutions based on actual deformation patterns—thus avoiding unnecessary over-support and minimizing resource waste. As a result, the mine achieves both effective cost control and enhanced safety assurance.

Intelligent Upgrade Direction

In the process of intelligent upgrading, introducing the integrated drilling and anchoring machine has become a key initiative to enhance the efficiency and precision of adit excavation. This machine combines two core functions—drilling and anchoring—enabling seamless, continuous operations that simultaneously complete tunnel excavation and rock bolt support directly on the same equipment, significantly boosting operational productivity. Equipped with the Beidou positioning system, the integrated machine is further empowered, achieving highly accurate automatic navigation. By leveraging satellite signals, the Beidou system delivers real-time, pinpoint location data, allowing the machine to maintain precise directional and positional control throughout the excavation process. As a result, the adit excavation accuracy reaches an impressive ±50mm. This high-precision excavation control not only minimizes errors caused by manual measurement and adjustment but also enhances the overall quality of the tunnel’s final shape, laying a solid foundation for subsequent mining operations. Compared to traditional excavation methods, the integration of the drilling-and-anchoring machine and the Beidou positioning system has boosted excavation efficiency by 30%. This advancement enables mines to complete adit development in significantly less time, accelerating the overall mining schedule and substantially improving the mine’s production capacity.

Building a 3D coupled model of adits and ore bodies is a crucial approach to achieving intelligent mine management. This type of model leverages digital twin technology to digitally map the real-world physical characteristics of adits and ore bodies, along with their geological information and various parameters from the mining process, ensuring comprehensive and precise representation. As a result, a highly accurate virtual replica of the actual mine environment is created, enabling detailed simulations of ventilation and transportation efficiency under different layout scenarios. In ventilation simulations, the model can precisely calculate airflow rates, wind speeds, and ventilation resistance in each underground area based on varying adit layouts and ventilation system parameters, thereby assessing whether ventilation performance meets safety standards and ensures comfortable working conditions. Meanwhile, in transportation efficiency simulations, the model predicts transportation time and costs by considering factors such as ore transport routes, equipment capabilities, and fluctuations in mining output, helping evaluate the overall rationality of the transportation system. By systematically analyzing and comparing these simulated scenarios, mine managers can make informed decisions about the optimal operational plan, ultimately optimizing resource allocation, enhancing overall mine efficiency, and boosting economic returns.

Previous Page