Overview of the Four Major Development Roadways in Underground Mining — Heijinggang Broadcast

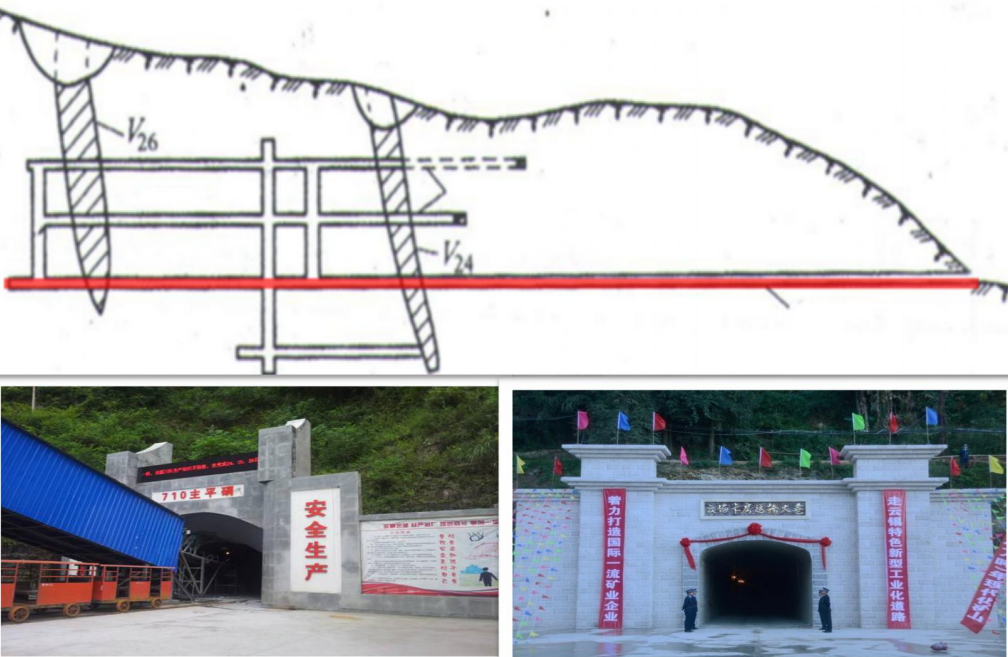

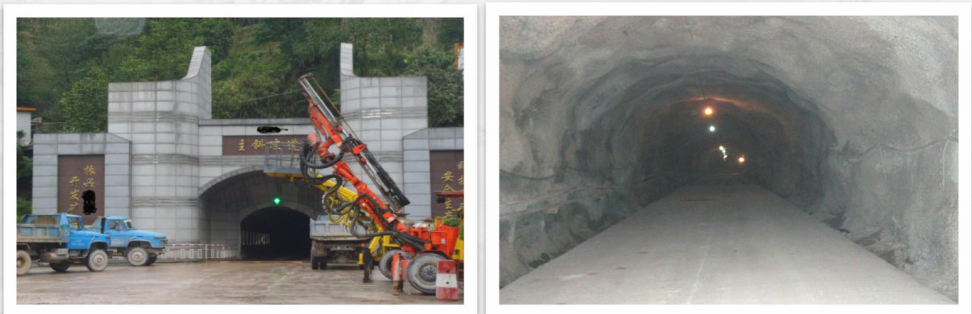

Adit Mining: The Economically Preferred Choice for Mountain Mining

Technological Advantages and Applicable Scenarios

As a horizontal tunnel directly connected to the surface, the adit occupies a unique position in mine development. From a construction perspective, it presents significantly lower technical challenges compared to shafts and inclined shafts. When constructing an adit, workers enjoy ample working space, making it relatively easy to carry out auxiliary tasks such as ventilation and drainage. Moreover, the operational environment for construction personnel is far more convenient, which greatly enhances overall efficiency. According to statistics, adit excavation typically proceeds 30% to 50% faster than shaft construction, meaning the project's infrastructure timeline can be substantially shortened. For instance, at a newly built mine originally planned for shaft-based development—with an estimated construction period of three years—a subsequent feasibility study led to a shift toward adit mining. As a result, the infrastructure phase was completed in just two years, enabling the mine to start production one year ahead of schedule and accelerating the overall development process considerably.

In terms of cost, the advantages of adit development are also particularly prominent. Due to its relatively low construction difficulty, it requires fewer equipment and manpower, resulting in significantly lower excavation costs per unit length compared to shaft development. Additionally, adits eliminate the need for complex hoisting equipment—such as headframes and hoists—that are essential for vertical shafts, thereby reducing expenses related to procurement, installation, and maintenance of such machinery. Moreover, adit development typically avoids the costly process of deep shaft excavation, further minimizing expenses associated with addressing challenging geological conditions. Overall, infrastructure investment for adit development can be reduced by approximately 30% compared to vertical shaft development.

The flat adit boasts robust transportation capacity, easily meeting the demands of large-scale ore hauling. Typically, motorized locomotives and mine cars are used as transport equipment in flat adits, ensuring a smooth and highly efficient operation. For large-scale mines, belt conveyors can also be employed for continuous transportation, further enhancing overall efficiency. Moreover, the transportation routes within flat adits are relatively straightforward, minimizing energy losses and reducing the risk of equipment failures at each stage—resulting in significantly lower transportation costs. Compared to shaft hoisting systems, flat adit transportation costs can be reduced by 40% to 60%.

In terms of ventilation, adit development naturally offers significant advantages. Since adits are directly connected to the surface, they can leverage natural air pressure for ventilation, substantially reducing both the initial investment and operational costs associated with mechanical ventilation systems. In mines situated in areas with favorable topographical conditions, adit ventilation can effectively combine natural and mechanical methods, ensuring high-quality air quality underground while simultaneously cutting down on ventilation energy consumption. According to calculations, the ventilation costs for adit development can be reduced by more than 50% compared to shaft development.

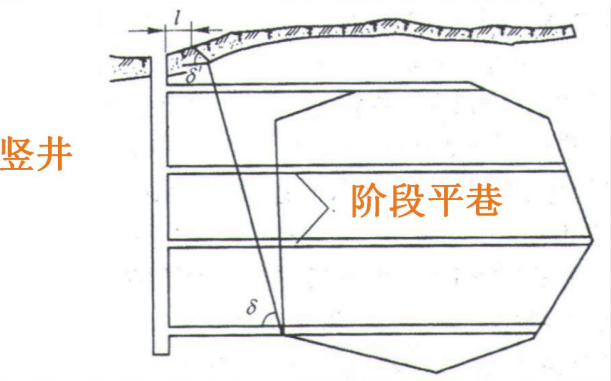

Shaft-and-level development is particularly well-suited for mountainous mining areas with intensely rugged terrain. In such regions, ore bodies are often buried deep within the mountains, and using shaft-and-level methods allows direct access to the ore deposits from the mountain’s side, thereby avoiding the challenges and risks associated with deep underground excavation. For instance, many metal mines in southwestern China, located in mountainous and geologically complex terrains, have achieved excellent results by adopting this approach. These mines have leveraged the relative spatial relationship between the shafts and ore bodies, carefully designing their development systems to ensure efficient and safe extraction operations.

Engineering Constraints and Optimization Directions

However, adit development is not without its challenges; when the length of an adit exceeds a certain limit, it inevitably encounters several engineering difficulties. As the adit length increases, the difficulty of ventilation during the excavation phase rises sharply. In long-distance adit driving, it becomes increasingly difficult to deliver fresh air efficiently to the working face, leading to deteriorating working conditions and reduced construction efficiency. To address this issue, it is typically necessary to install high-power axial fans along with dedicated ventilation ducts, which forcibly pump fresh air directly to the excavation area. Yet, this approach undeniably drives up ventilation costs—according to data from actual projects, when the adit length surpasses 1,500 meters, the cost per meter of excavation can increase by 20% to 30% due to the heightened ventilation demands.

Pipeline maintenance in long-distance adits has also become a prominent issue. As the length of the adits increases, so do the lengths of power, water supply, and drainage pipelines—significantly boosting both the initial investment costs and the challenges associated with maintaining these systems. During adit operations, regular inspections, repairs, and replacements of the pipelines are essential to ensure their smooth functioning. According to statistics, pipeline maintenance costs for long-distance adits have been rising by about 15% annually on average, placing considerable financial strain on mine operations.

Additionally, long-distance adits also face challenges related to surrounding rock stability. Given the complex geological formations that the adits traverse, prolonged mining activities may lead to deformation, fracturing, or even collapse of the surrounding rock. To ensure the safe operation of the adits, it is essential to strengthen monitoring and support measures for the surrounding rock. Implementing intelligent monitoring systems can enable real-time tracking of rock deformation, allowing operators to promptly identify potential safety risks and take appropriate reinforcement actions, such as anchor bolt support or shotcrete lining.

To address these challenges, a series of optimization measures have been proposed in engineering practice. In terms of ventilation design, a segmented ventilation approach can be adopted, with a ventilation connecting passage set every 500 meters, dividing the long-distance adit into several ventilation segments. By strategically arranging ventilation equipment and airflow routes, this method enhances ventilation efficiency while reducing costs. Regarding support systems, high-strength anchor rod technology is employed, increasing both the length and density of the anchors to further improve the stability of the surrounding rock. Implementation of these optimized measures can reduce the safety risks associated with long-distance adits by approximately 40%, effectively ensuring the safe and efficient development of the adit.

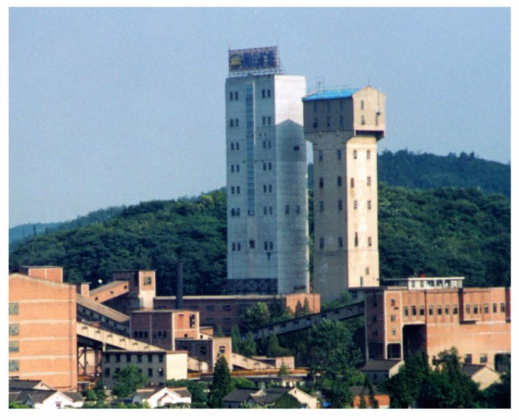

Shaft: The Vertical Lifeline of Deep Mineral Deposits

Efficiently Enhancing System Development

The vertical shaft, serving as a direct vertical mine access to the surface, plays a critical role in mine development—it can rightly be called the "vertical lifeline" for deep-mining operations. As the primary channel for hoisting ore, the efficiency of the hoisting system directly determines the mine's overall production capacity. Today, advanced multi-rope friction hoists have become the mainstream equipment for main shaft hoisting. These hoists boast exceptional lifting capabilities, with a single cage capable of transporting up to 60 tons per trip, significantly boosting ore-handling efficiency. For instance, at a large-scale metal mine, after adopting multi-rope friction hoists in its main shaft, annual hoisting capacity successfully exceeded 10 million tons, effectively supporting the mine’s massive production requirements.

The cross-sectional design of the main shaft is also critically important. Through optimized design, its cross-sectional utilization rate can reach over 85%, meaning that greater hoisting capacity can be achieved within a limited space. In terms of ventilation, the vertical shaft, combined with a multi-stage fan station ventilation system, effectively reduces ventilation resistance. Compared to inclined shafts, the ventilation resistance in vertical shafts can be reduced by up to 30%, allowing fresh air to flow more smoothly to all working areas underground and creating an excellent environment for miners. The multi-stage fan station ventilation system achieves precise control over airflow by strategically placing fan stations at various locations, ensuring that underground air quality meets the stringent requirements of deep mines extending thousands of meters below ground.

The auxiliary shaft is equally indispensable in the vertical shaft development system, primarily responsible for critical tasks such as ventilation, drainage, and the transportation of personnel and materials. To enhance the efficiency of personnel transport, the auxiliary shaft is equipped with a dual-cage + counterweight system, enabling cage speeds of up to 8 m/s—significantly reducing the time required for workers to ascend or descend the shaft. Compared to single-cage hoisting systems, the dual-cage system boosts lifting efficiency by 40%, effectively meeting the demands of large-scale personnel transportation in mining operations. Additionally, when it comes to lowering materials, the auxiliary shaft’s dual-cage system ensures highly efficient operations, guaranteeing that essential supplies reach the mine site promptly to support underground production activities.

Geological Adaptability and Engineering Challenges

While shaft development offers numerous advantages, it also faces a series of engineering challenges when confronted with complex geological conditions. When the dip angle of the orebody is less than 30°, an exceptionally long stope must be constructed between the shaft and the orebody to ensure connectivity. These stopes often stretch up to 800 meters in length, significantly increasing the overall development workload and substantially extending the construction timeline. According to statistics, building these ultra-long stopes can boost the total development volume by as much as 25%, placing considerable pressure on both the mine's construction costs and project schedule.

Deep shafts also face the challenge of ground pressure manifestation. As mining depth increases, ground pressure gradually intensifies, posing a serious threat to the stability of the shaft walls. To address this challenge, engineering practices typically employ C30 reinforced concrete shaft linings embedded with steel fiber-reinforced layers. This composite structural design boasts superior strength and toughness, effectively resisting ground pressure while keeping shaft wall deformation within 3 mm per 100 meters—thus ensuring the safe and stable operation of the shaft.

During shaft construction, employing the reverse shaft drilling rig for pilot hole drilling combined with blast expansion is an effective technical approach. This method first uses the reverse shaft drilling rig to create a pilot hole, followed by blast-induced expansion to form the shaft. Compared to conventional construction methods, this technique can reduce the shaft-building cycle by 15%, while also minimizing the risks associated with high-altitude operations, thereby enhancing both construction safety and efficiency. By carefully selecting appropriate construction techniques and optimizing the design of the shaft lining structure, it becomes possible to effectively address geological challenges encountered during shaft development, ultimately enabling safe and efficient extraction of deep-seated mineral resources.

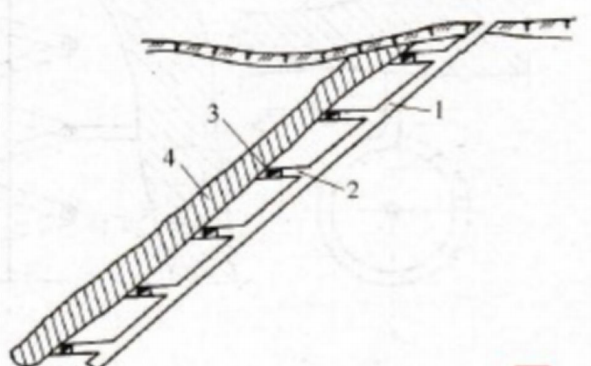

Inclined shaft: A flexible option for medium-depth ore bodies

Economically efficient inclined transportation solution

As an inclined roadway directly connected to the surface, the decline shaft demonstrates unique advantages in mine development, making it a flexible choice for mining medium-depth ore bodies. From an economic perspective, the construction workload for a decline shaft is relatively smaller—about 30% less than that of a vertical shaft. This is primarily due to the simpler construction process of a decline shaft, which doesn’t require the deep, vertical excavation needed for a vertical shaft, thereby reducing both construction complexity and overall project volume. Additionally, construction progress is significantly faster, allowing mines to complete infrastructure work more swiftly and advance into the production phase earlier. As a result, companies can save substantial time and costs, unlocking economic benefits ahead of schedule.

The applicable orebody conditions for inclined shafts fall within a specific range, making them particularly suitable for orebodies with dip angles between 15° and 45° and depths ranging from 200 to 500 meters. Within this range, inclined shafts can fully leverage their advantages, enabling efficient mining operations. For instance, at a certain metal mine, where the orebody had a dip angle of 30° and a depth of 350 meters, adopting an inclined shaft approach significantly boosted mining efficiency while markedly reducing production costs.

In terms of transportation capacity, inclined shafts perform exceptionally well. The main inclined shaft equipped with a belt conveyor boasts impressive hauling capabilities, with a single machine capable of transporting materials over distances up to 2,000 meters and achieving hourly output exceeding 1,500 tons. Compared to the traditional skip hoisting method, the belt conveyor system boosts transportation efficiency by approximately three times, easily meeting the production demands of large-scale mines. Meanwhile, the auxiliary inclined shaft features a trackless rubber-tired vehicle system, further enhancing the flexibility and efficiency of material transport. These trackless rubber-tired vehicles can directly deliver personnel and materials to the working face without the need for intermediate transfers, significantly reducing commute time—by about 40% compared to conventional rail-based systems.

Enhancing Capabilities and Addressing Pain Points

However, inclined shaft development also has some drawbacks. Compared to vertical shafts, inclined shafts have relatively limited hoisting capacity. The lifting speed in inclined shafts is restricted—typically, wire-rope traction systems can achieve speeds no more than 5 m/s—thus limiting the efficiency of ore extraction. Moreover, the wear rate of hoisting equipment tends to be higher, with wire ropes lasting about 25% shorter than those used in vertical shafts. This is because, during inclined shaft operations, the wire ropes experience greater friction against the shaft walls and are subjected to uneven tensile forces, leading to accelerated wear. As a result of this increased equipment wear, the annual maintenance costs for inclined shafts are approximately 18% higher than those for vertical shafts, placing additional pressure on the mine's operational expenses.

In terms of maintenance, inclined shafts also face several challenges. In some geologically sensitive mining areas, the tunnels of inclined shafts are prone to deformation due to ground pressure. To ensure the safe operation of inclined shafts, it is essential to adopt a combined support system featuring steel mesh sprayed with concrete alongside steel arch supports, with the spacing between steel arches typically set at 0.8 meters. This advanced support method effectively controls the rate of tunnel deformation, keeping it below 0.5 mm per month. To enhance the safety and reliability of inclined shaft hoisting operations, an intelligent monitoring system for inclined shaft lifting can be introduced. This system continuously tracks the condition of wire ropes in real time, with a detection sensitivity as high as 1 broken strand per 100 meters. Should any broken strands or other anomalies be detected, the system immediately triggers an early warning alert. Additionally, the system provides real-time alerts for potential runaway car risks by monitoring and analyzing the operational parameters of the hoisting equipment, enabling proactive measures to prevent such hazards before they occur. 4

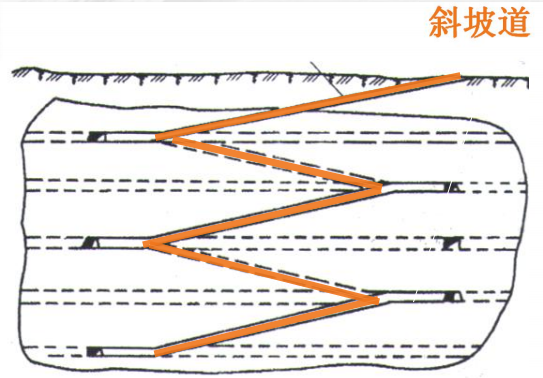

Slope Road: The Key Passage for Trackless Mining

The core carrier of mechanized operations

In modern mining operations, ramp systems occupy a critical position as the core pathway enabling trackless mining. They allow trackless equipment—such as loaders and rock-drilling rigs—to directly enter and exit underground, fundamentally transforming traditional mining practices and paving the way for fully mechanized mining processes. For instance, in a state-of-the-art metal mine, the introduction of ramp systems boosted single-shift operational efficiency by 60%. Under conventional mining methods, cumbersome equipment movements and inefficient transitions between operational stages severely hindered productivity. However, with the advent of ramp systems, trackless machinery can now seamlessly navigate through various underground work areas, significantly enhancing operational continuity and overall efficiency.

The layout of ramp systems is highly flexible, and reversing ramps are particularly well-suited for complex terrains. These ramps can feature a minimum turning radius as small as 15 meters, easily accommodating the passage of 20-ton trucks. In practical engineering applications, carefully designing the ramp alignment allows for effective adaptation to diverse topographical conditions, thereby enhancing mining operations' efficiency. For instance, in mountainous mining areas with significant elevation changes, the implementation of reversing ramps has successfully addressed the challenges of both equipment and ore transportation.

The slope of a ramp significantly impacts the operational efficiency and energy consumption of trackless equipment. Research shows that when the slope is kept within 12%, the fuel efficiency of trackless machinery can improve by up to 12%. This is because, at gentler slopes, the running resistance decreases, reducing the engine load and, consequently, lowering fuel consumption. When designing ramps, it’s essential to carefully control the slope based on the equipment’s performance characteristics and the specific conditions of the mine, in order to enhance both operational efficiency and cost-effectiveness.

During the exploration phase, the ramp can also serve as a geological exploration passage, significantly reducing the amount of engineering work required for dedicated exploration drifts. According to statistics, utilizing the ramp for geological surveys can cut down the workload of specialized exploration drifts by 30%. Traditionally, geological exploration necessitates the construction of dedicated drifts, which not only drives up project costs but also prolongs the overall exploration timeline. In contrast, leveraging the ramp for geological surveys helps both save on engineering expenses and accelerate the exploration process, providing strong support for the mine's subsequent development efforts.

The technological bottleneck in deep exploration

However, as mining depth increases, the ramp faces a series of technical bottlenecks. When the depth exceeds 400 meters, ventilation costs rise sharply. This is because, as depth increases, ventilation resistance grows significantly, necessitating the installation of additional relay fan stations to maintain effective airflow. Typically, a relay fan station must be set up every 300 meters, which undeniably drives up both the construction and operational costs of the ventilation system. Moreover, trackless equipment emits exhaust gases during underground operations—gases that contain high levels of harmful pollutants and particulate matter, leading to PM2.5 concentrations exceeding safe limits underground and posing serious health risks to workers. To address this issue, it is essential to equip the system with highly efficient air purification devices capable of achieving a purification efficiency of 95% or higher. By installing these air purifiers, we can effectively eliminate harmful components from the exhaust gases, thereby improving overall air quality underground.

During the infrastructure phase, tunneling on steep ramps with large gradients (>15%) also presents numerous challenges. Due to the significant slope, it becomes difficult for tunneling equipment to move and operate effectively, resulting in a 25% reduction in excavation efficiency. To ensure smooth progress of the tunneling work, special technical measures must be implemented. For instance, anti-slip road surfaces should be used, and the hardness of concrete aggregates must reach at least 60 HRC or higher to enhance friction between the equipment and the roadway. Additionally, an intelligent drainage system is required, capable of handling up to 50 m³/h of water, to promptly remove accumulated water from the surface and maintain safe operation of the equipment.

Conclusion: Collaborative Innovation Through Multidimensional Expansion

The four major development roadways each have their own technical advantages and application boundaries. In modern mining operations, a single development method often fails to meet the complex demands of extraction; thus, the combined development approach has emerged. In several large-scale mining projects, shallow ore bodies typically utilize adit development, leveraging its ease of construction and rapid ore extraction capabilities to achieve swift production while minimizing initial investment costs. As mining depth increases, intermediate ore bodies can be developed via inclined shafts, seamlessly transitioning between methods and capitalizing on the inclined shaft’s advantages: lower infrastructure requirements and quicker time-to-production. Meanwhile, deep-seated ore bodies rely on vertical shafts for efficient hoisting, benefiting from the shaft’s substantial lifting capacity and remarkable adaptability—qualities that ensure the high-efficiency transportation of deep-level ores. Additionally, the presence of ramps facilitates trackless operations, enabling automated equipment to move freely underground and significantly enhancing the mechanization and智能化 level of mining processes.

To further optimize the development system, modern mines are widely adopting BIM technology for 3D modeling. With BIM technology, engineers can visually present the spatial layout of development roadways, identify potential design issues in advance, and make timely optimizations and adjustments. According to analysis of real-world cases, applying BIM technology to develop system designs can improve roadway space layouts by 15%–20%, significantly enhancing space utilization. Moreover, optimizing roadway layouts helps minimize unnecessary engineering work, ultimately reducing overall development costs by up to 12%.