A Study on the Historical Development and Innovative Discoveries of Drill Tip Technology — Heijinang Broadcast

1. The development history and evolution of drill-tip technology in the field of mechanical processing

As a crucial cutting tool, the history of the drill bit dates back to prehistoric times. The evolution of drill-tip technology serves as a microcosm of humanity's advancements in craftsmanship and the ongoing progress of materials science.

Early Development (Prehistoric to the Middle Ages):

- Prehistoric period (circa 35,000 BCE): Early Homo sapiens discovered that rotating tools could be used for drilling. Initially, they employed smooth wooden sticks fitted with flint tips to create holes. By the Late Paleolithic period, the materials expanded to include bone, shells, and deer antlers.

- Ancient Egyptian period: Ancient Egyptians primarily used wood as drill bits, generating rotational motion by wrapping bowstrings around wooden sticks. These drill bits were employed not only for starting fires but also in woodworking, dentistry, and stone carving.

- 13th century: Humans began using metal as drill bits. By incorporating copper sheets inside a tubular wooden stick, they were able to drill holes by grinding the outer area, thereby minimizing damage to the material.

- Ancient Rome and China: The Romans invented augers for use in construction and metalworking. Around 200 B.C., China made significant advancements in drill technology, developing sophisticated drills and augers tailored for woodworking, masonry, and medical applications. More importantly, China pioneered deep-well drilling techniques, enabling the excavation of saltwater wells that reached depths exceeding 1,000 feet—crucial for the salt-production industry.

- The Medieval and Renaissance Periods: Drilling tools and drill bits were further improved during this period, largely due to advancements in blacksmithing and metallurgical techniques.

Modern Development (19th to early 20th century):

- 1806: For the first time on record, the United States drilled a spring-rod well reaching a depth of 58 feet, laying the foundation for spring-rod drilling in the petroleum industry.

- 1821: The first U.S. well specifically drilled for natural gas extraction was completed in Fredonia, New York.

- 1825: The four-legged derrick has been patented, and its structure is made from square timber.

- 1844: Brunton invented the first mechanized impact drill, which uses compressed air to generate striking power.

- 1861: Stephen A. Morse invented the twist drill and received a patent for it in 1863. His design improved upon the inefficient shovel-shaped drills of the time by incorporating spiral flutes that efficiently remove chips from the cutting edge, reducing clogging and enhancing cutting quality. Since then, the basic design of the twist drill has remained largely unchanged.

- 1863: Peter Sweeny made significant improvements to rotary drilling technology based on the design by Robert Beart, enabling nearly continuous drilling and enhancing hole cleaning.

- Early 1900s (Oil and Gas Industry): Rotary drilling technology emerged, utilizing steam-powered drills and simple flatfish-bit tools. While fish-bit drills performed well in soft formations, they wore down rapidly when used in hard rock.

- 1909: Howard Hughes Sr. and Walter Sharp were granted a patent for the two-cone roller bit. This drill bit replaced the dull fish-tail drill with two interlocking steel cones, each embedded with numerous teeth or cutting blades. As the bit rotates, the cones roll freely on bearings, crushing the rock rather than scraping it—resulting in a significant improvement in drilling efficiency when working through medium-to-hard formations.

- 1917: The shape of modern hand drills, including the pistol-style grip and trigger-type start button, originates from a patent by Black & Decker.

- 1933: The three-cone roller bit was developed, offering more efficient and balanced cutting, and became the mainstream drill bit of the mid-20th century.

Modern Development (1970s to Present):

- From the 1970s to the present: The polycrystalline diamond compact (PDC) drill bit has revolutionized drilling technology with its exceptional durability and significantly higher rate of penetration (ROP), making it particularly well-suited for shale and other abrasive formations. Featuring no moving parts, PDC drill bits deliver remarkably fast drilling speeds in a wide range of geological formations.

- 2000s: The introduction of thermally stable PDC (TSP) tools enables cutting even harder rocks at high temperatures.

- Contemporary: Modern drill bits combine advanced cutting-edge technology, 3D modeling design, and real-time performance feedback enabled by digital systems. For instance, brushless motor technology enhances both the power and longevity of the drill bit. Stealth drilling technology ensures straighter operation, resulting in cleaner holes, while also promoting even wear across the bit to minimize chip formation. In fracking operations, hybrid tools streamline the drilling process even further.

2. The Background and Innovative Opportunity Behind the Discovery of Non-Coaxial Helical Surface Drill Tip Technology

Non-coaxial helical-flute drill tip technology represents a significant innovation in the field of drill tip geometry design. Its discovery was primarily driven by an awareness of the performance limitations inherent in conventional drills, as well as the growing demand for greater machining accuracy, efficiency, and tool life.

Discovery context:

- The Complexity and Limitations of Traditional Drill Bit Geometry: The geometry of twist drills is remarkably complex. Although their basic design has remained largely unchanged since Stephen A. Morse invented them in 1861, there is still room for optimization in terms of cutting forces, torque, chip formation, and hole quality. Traditionally, the tip of a twist drill features a coaxial helical surface—meaning the axis of the helical surface aligns perfectly with the axis of the drill body. However, under certain machining conditions, this design can lead to excessive cutting forces, poor chip evacuation, uneven tool wear, and issues affecting hole quality, such as delamination, burring, and chipping along the edges.

- Challenges in the micro-drilling field: With the advancement of miniaturization technology, the demand for micro-hole machining is steadily increasing. Micro-drills face greater challenges during the machining process, such as easy breakage, difficult chip removal, and significant difficulties in controlling hole quality. Traditional coaxial designs, when applied to micro-drill sizes, may fail to meet high-precision requirements due to their limited cutting performance and stability.

- Optimization requirements for cutting force, temperature, and wear: During the drilling process, cutting forces, tool temperature, and wear are key factors that influence machining efficiency, tool life, and hole quality. Researchers have been continuously striving to minimize these adverse effects by optimizing drill tip geometry. For instance, reducing the drill tip length can significantly lower cutting forces, tool temperature, and wear.

Opportunities for innovation:

- The development of mathematical modeling and simulation technologies: With the advancements in computer-aided design (CAD) and finite element analysis (FEA) software, researchers are now able to mathematically model and simulate complex drill tip geometries with greater precision. This capability allows them to predict how different drill tip designs will affect cutting performance before actual manufacturing begins, thereby accelerating the exploration and validation of new designs. For instance, geometric parameters of non-coaxial helical drill tips can be calculated using MATLAB software, while microdrilling simulations are conducted via DEFORM-3D software.

- A deeper understanding of chip formation and chip evacuation mechanisms: In-depth research into the mechanisms of chip formation, curling, and evacuation reveals that optimizing chip morphology is crucial for enhancing drilling performance. The non-coaxial helical surface design can influence the degree of chip curling and the evacuation path by altering the geometry of the cutting edge, thereby improving chip removal efficiency, reducing chip clogging, and minimizing heat buildup.

- Analysis of Tool Wear Patterns: Through a detailed analysis of the tool wear patterns, it was found that certain areas of the conventional drill tip—such as the cutting lip angle and the transverse edge—experience the fastest wear during the cutting process. The non-coaxial design aims to optimize the stress distribution in these critical regions, thereby extending the tool's lifespan.

- Attention to Hole Quality Defects: Common hole quality defects during drilling, such as delamination, chipping, burrs, and surface roughness, have prompted researchers to explore new drill tip geometries aimed at addressing these issues. Non-coaxial helical drill tips, by optimizing the distribution of cutting forces and heat during the process, help enhance both hole integrity and surface quality.

- The development of CNC grinding technology: The emergence of advanced manufacturing equipment, such as six-axis CNC grinders, has made it possible to produce micro-drills featuring complex, non-coaxial helical surfaces—enabling the transformation of theoretical designs into tangible products.

In summary, the discovery of the non-coaxial helical drill tip technology stems from a deep understanding of the performance limitations inherent in conventional drill bits, and it benefits from advanced mathematical modeling, simulation, and manufacturing techniques—all aimed at overcoming specific machining challenges and achieving superior drilling performance.

3. Geometric Differences Between Traditional Coaxial Helical Drill Tips and Non-Coaxial Helical Drill Tips

The primary geometric difference between traditional coaxial helical drill points and non-coaxial helical drill points lies in the relationship between the helical surface axis and the drill body axis.

1. Traditional Coaxial Spiral Drill Bit:

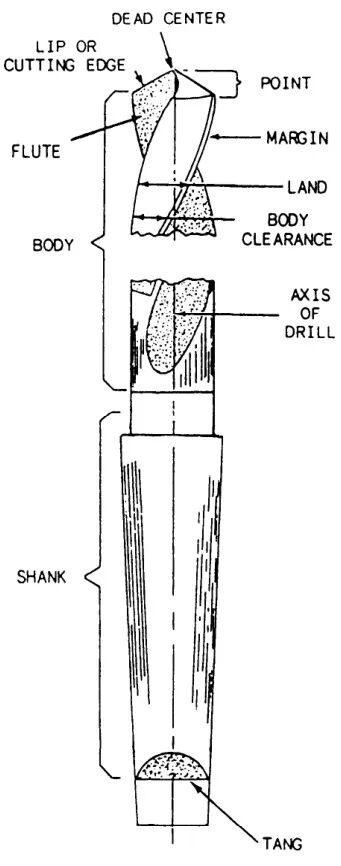

- Definition: The helical flutes and cutting edges of a traditional twist drill have their spiral axes coinciding with the drill’s main axis—specifically, the axis of the drill body.

- Geometric features:

- Helical Groove: It spirals along the drill bit's axis, serving to remove chips and guide coolant.

- Cutting Lips: Formed by the intersection of the helical flutes and the conical surface of the drill tip, it serves as the primary cutting section.

- Chisel Edge: Located at the center of the drill tip, connecting the two cutting lips, it is typically the area where drilling force is greatest.

- Point Angle: The included angle between the two cutting lips of the drill point typically ranges from 118° to 135°. A 118° angle is ideal for soft metals, while a 135° angle is better suited for hard materials and handheld drilling applications.

- Clearance Angle: The angle between the cutting edge and the workpiece surface, designed to reduce friction.

- Complexity: Although it may seem simple, the geometry of a twist drill is actually quite complex, with its cutting logic involving multiple angles and curved surfaces.

- Advantages: It has a relatively simple structure, is easy to manufacture, highly versatile, and widely used for drilling holes in various materials.

- Limitations: Under certain extreme conditions—such as micro-drilling and machining hard materials—issues like high cutting forces, poor chip evacuation, poor hole quality, and rapid tool wear may arise.

2. Non-coaxial Helical Flank Micro-drill:

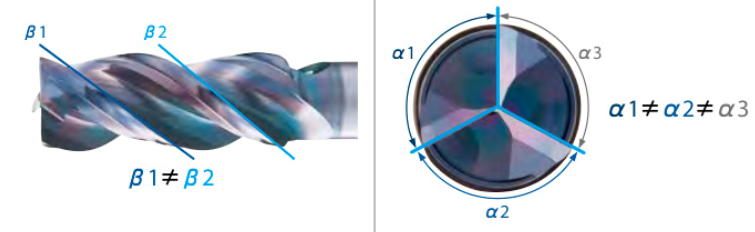

- Definition: The helical axis of the non-coaxial spiral-flute drill bit forms an angle (φ) with the axis of the drill body—meaning the helical axis does not coincide with the main axis of the drill. This design is typically used in micro-drills to optimize their cutting performance.

- Geometric features:

- Helical surface axis deviation: This is the most essential feature. By angling the helical surface axis relative to the drill body axis, it becomes possible to alter the geometry of the cutting edge—particularly in the transverse edge region and the rake angle of the cutting lips.

- Optimizing the Flute: Non-coaxial designs are often combined with techniques such as "cross-shaped chisel edge thinning." By reducing the length of the cross-shaped edge, drilling forces, tool temperatures, and wear can be significantly minimized. In contrast, micro-drills without a cross-shaped edge may experience higher torque and tool temperatures, leading to the formation of long, ribbon-like chips.

- Cutting Edge Geometry Adjustment: This non-coaxial design allows for more flexible adjustments of the rake angle, lip inclination angle, uncut chip thickness, and uncut chip width, thereby optimizing the cutting process.

-

- Complexity: The geometric design and manufacturing of non-coaxial helical drill points are more complex than those of traditional coaxial drill tips, requiring advanced mathematical models and high-precision CNC grinding machines for implementation.

- Advantages:

- Reduce cutting force: By optimizing the transverse edge and cutting edge geometry, it is possible to effectively reduce drilling forces and minimize vibrations and heat generated during the machining process.

- Improve chip removal: By adjusting the degree of chip curling and the chip evacuation path, enhance chip removal efficiency and prevent chip clogging.

- Extending Tool Life: Reduce tool wear, especially in critical cutting areas, thereby extending tool life.

- Improve hole quality: Reduce the occurrence of defects such as delamination and burrs, and improve hole precision and surface quality.

- Suitable for micro-drilling: It demonstrates superiority in the micro-drill field and can meet the demands of high-precision micro-hole machining.

- Applications: Primarily used in fields that demand extremely high machining precision and efficiency, such as aerospace, electronics, medical devices, and especially in micro-hole machining.

The following table summarizes the key differences between the two drill tip geometries:

| Features | Traditional Coaxial Helical Drill Tip | Non-coaxial helical drill tip |

|---|---|---|

| Helical Surface Axis | Coinciding with the drill bit body axis | It forms an angle (φ) with the drill body axis, but does not coincide. |

| Cross Blade | Longer, area of concentrated cutting force | Can be significantly shortened and cutting forces reduced through design optimization (such as cross-shaped thinning). |

| Cutting Edge Geometry | Relatively fixed, with limited room for optimization | More flexible and adjustable, allowing optimization of rake angle, lip inclination angle, and more. |

| Creating Complexity | Relatively simple | Complex, requiring advanced mathematical models and high-precision CNC grinding machines. |

| Main Advantages | Highly versatile, with relatively low manufacturing costs. | Reduce cutting force, improve chip evacuation, extend tool life, and enhance hole quality. |

| Typical Applications | Widely used for universal drilling in various materials | Micro-drilling, high-precision machining, difficult-to-machine materials |

Non-coaxial helical drill tip technology represents an important direction in the development of drill tip geometry design, enabling deeper optimization of the drilling process through precise geometric control.