Detailed Explanation of Physical and Proportioning Parameters for Filling Materials: The Key to Optimizing Filling Mining Efficiency and Quality—HeijinGang Report

I. Physical and Mechanical Parameters of Filling Materials

In mining engineering, the selection and application of backfill materials are critical components of the fill-and-mine method. The physical and mechanical properties of the backfill material directly determine the strength, stability, and mining efficiency of the backfill body.

The following is a detailed description of the main physical and mechanical parameters of the filling material:

Density

Density refers to the mass of a filling material per unit volume in its compacted state, serving as an important indicator that reflects the uniformity of the material's quality distribution. In fill mining, the density directly influences both the quality of the backfill and the efficiency of the mining process. If the density is too low, it may result in insufficient strength of the backfill, compromising the stability and safety of the mine; conversely, if the density is too high, it could drive up backfilling costs while reducing mining efficiency. Therefore, when selecting backfill materials, it’s essential to carefully determine the appropriate density based on the specific conditions of the mine and the requirements of the mining operation.

Loose density

Loose density refers to the mass of a filling material per unit volume in its loose, uncompacted state. Compared to density, loose density better reflects the physical properties of the filling material as it exists naturally. During the filling process, the magnitude of loose density directly influences the compactness and porosity of the filled material, which in turn affects the strength and stability of the fill body. Therefore, when selecting filling materials and designing the filling process, it is essential to fully consider the impact of loose density.

Porosity Ratio and Porosity

Loosely packed backfill materials contain a high volume of pores, which significantly influence the strength of the backfill body. The void ratio refers to the proportion of pore volume to the total volume of the backfill material, while porosity represents the percentage of pore volume relative to the overall volume. Both the void ratio and porosity directly determine the compactness and permeability characteristics of the backfill body. Excessively high porosity can weaken the backfill’s structural integrity, whereas too-low porosity may impair its permeability, making it difficult for excess water to drain away. Therefore, when selecting backfill materials and designing the filling process, it is essential to carefully control the values of both the void ratio and porosity.

Moisture Content

The moisture content in the backfill material also serves as the basis for calculating its density, porosity, and degree of water saturation. The magnitude of the moisture content directly affects the strength and stability of the backfill. Excessively high moisture levels can weaken the backfill, potentially leading to safety issues such as collapse, while too low moisture content may result in an overly dry backfill that struggles to achieve proper compaction. Therefore, during the backfilling process, it is essential to strictly control the moisture content to ensure both the quality and stability of the backfill material.

Permeability coefficient

The permeability coefficient typically refers to the rate at which water passes through a packed material aggregate under 20°C conditions. In backfill mining, the magnitude of the permeability coefficient directly determines the permeability performance of the backfill body. When using hydro-sand backfilling, it is essential to remove excess water; thus, the backfill material must possess adequate permeability. If the permeability coefficient is too high, the backfill may lose water excessively and rapidly, compromising its strength and stability. Conversely, if the coefficient is too low, it may become difficult to drain excess water, driving up backfilling costs. Therefore, when selecting backfill materials and designing the backfilling process, it is crucial to carefully control the permeability coefficient within an appropriate range.

Filler particle shape and particle size distribution

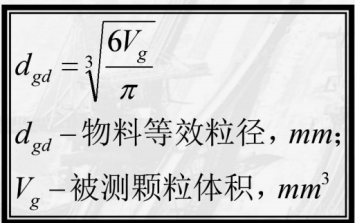

The shape and size of backfill material particles significantly influence the quality of the backfill body. Since backfill particles often have irregular shapes, their sizes are typically described using an equivalent particle diameter—defined as the diameter of a sphere with the same volume as the particle. Both the shape and size of the particles directly affect the compactness and porosity of the backfill body, which in turn impact its strength and stability. Therefore, when selecting backfill materials and designing the filling process, it is essential to thoroughly consider the effects of particle shape and size.

Since the particles of this filler material are irregular, not round, we typically use an equivalent particle diameter to describe their size. The equivalent particle diameter of this material is calculated using the following formula.

By using this formula, you can calculate the equivalent particle size of a filled granule.

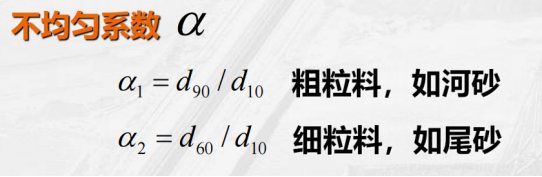

Particle-size distribution characteristic values

To more accurately describe the particle size distribution of backfill materials, it is often necessary to calculate several characteristic values. These include the median particle size, effective particle size, average particle size, and uniformity coefficient, among others. The median particle size refers to the particle diameter corresponding to 50% cumulative content, while the effective particle size is the diameter at which 10% cumulative content is reached. The average particle size represents the weighted mean diameter of the particles, and the uniformity coefficient reflects the degree of uniformity in the particle size distribution. The magnitudes of these characteristic values directly influence the quality and stability of the backfill material. Therefore, when selecting backfill materials and designing the filling process, it is essential to fully consider the impact of these key parameters.

The following formula is used to calculate the average particle size.

Then, by calculating the weighted average of the contents corresponding to different particle sizes, we can obtain the overall average value for the entire particle size range.

The coefficient of uniformity is calculated using the following two formulas.

II. Grouting Slurry Mixing Ratio Parameters

The mixing ratios of the filling slurry are one of the key factors influencing both the quality of the backfill and mining efficiency. Below is a detailed description of the primary mixing parameters for the filling slurry:

Ash-sand ratio

The fly-ash-to-sand ratio refers to the proportion of cementitious materials to aggregates by mass. In backfill mining, the magnitude of the fly-ash-to-sand ratio directly affects the strength and stability of the backfill material. A ratio that is too high may lead to increased backfill costs, while a ratio that is too low could result in insufficient strength of the backfill. Therefore, when selecting backfill materials and designing mix proportions, it’s essential to carefully control the fly-ash-to-sand ratio. Additionally, other factors—such as the influence of cement, fly ash, and other cementitious materials—must also be taken into account to ensure the quality and stability of the backfill.

Water-cement ratio

The water-to-cement ratio refers to the proportion of water to cement. In filling mining, the magnitude of the water-to-cement ratio directly affects the strength, stability, and flowability of the backfill material. A water-to-cement ratio that is too high may lead to reduced backfill strength and even pose safety risks such as collapse, while a ratio that is too low could result in an overly dry backfill, making it difficult to achieve a dense, compact structure. Therefore, during the filling process, it is essential to strictly control the water-to-cement ratio to ensure the quality and stability of the backfill. At the same time, other factors—such as water quality and cement type—must also be taken into account to optimize the performance of the backfill material.

We previously mentioned that water, on one hand, acts as a crucial ingredient for mixing and blending cement with aggregates, creating a fluid slurry. On the other hand, water also plays an essential role in facilitating the transportation of this material through pipelines. Typically, we rely on pipelines to convey the filling slurry, making water indispensable during this process. However, the water-to-cement ratio significantly impacts the strength and quality of the filling material—too much water can actually weaken the final product. Moreover, any excess water must be drained away underground, which is why carefully controlling the water-to-cement ratio is critical.

Quality Concentration

Quality concentration is an important indicator for assessing the flow properties and quality of filling slurries. It can be expressed either as volume concentration or mass concentration. In fill mining, the magnitude of quality concentration directly affects the compactness, strength, and stability of the backfill body. Excessively high quality concentration may reduce the fluidity of the slurry, making it difficult to transport to the mining area; conversely, too low a concentration could lead to insufficient strength in the backfill. Therefore, when selecting filling materials and designing mix ratios, it’s crucial to properly control the quality concentration to ensure both the quality and stability of the backfill. Additionally, it’s essential to consider the varying requirements for quality concentration across different filling systems, such as water-sand filling, cemented filling, and paste filling.

The filling slurry mix ratio parameters are primarily influenced by the following factors.

The first filling material—different filling materials will influence various mix ratios. For instance, river sand, fine sand, tailings, rod-milled sand, or even gangue and waste rock—each of these distinct filling materials requires a unique mix ratio, which differs from the ratio used with cement.

The second is the system itself—our systems include cemented backfill, water-sand filling, and gangue-based backfill. For these different systems, the mixing and production processes vary accordingly.

The third filling multiple—where the filling multiple refers to the ratio of the total length of the filling pipeline from the surface to the filling point, divided by the vertical distance from the surface to the filling point.

The fourth aspect is the specific requirements for the quality of backfill materials in mining operations. Is it room-and-pillar filling or stope filling? Naturally, different mining areas will have varying demands on the strength of the backfill material. Therefore, the optimal mix ratio is typically determined through laboratory tests rather than being calculated arbitrarily. After all, different mines, different types of backfill materials, and even distinct stopes and filling points each impose unique criteria on the quality of the backfill.

III. Flow Performance Parameters of the Filling Slurry

The flow properties of the filling slurry are one of the key factors influencing filling efficiency and the quality of the filled material.

After the filling slurry is prepared, it needs to be transported from the preparation point to the mining area—either through pipelines or other methods. Once at the mining site, the slurry must maintain a certain level of fluidity to ensure efficient and thorough filling of the mine voids. We primarily evaluate the flowability of the filling slurry based on the following key aspects.

The following is a detailed description of the key flow performance parameters of the filling slurry:

Traffic and Flow Rate

The production capacity of a filling system is typically expressed in terms of the slurry flow rate. Both the flow rate and flow velocity directly influence the compactness and strength of the filled material. During the filling process, it’s essential to carefully determine the appropriate slurry flow rate and velocity based on the size of the mining area and specific filling requirements. Additionally, factors such as pipe diameter and filling multiplication ratio must be taken into account to ensure the quality and stability of the filled material.

Critical Flow Velocity

The critical flow velocity refers to the minimum speed required to keep the filling slurry suspended during transportation. To prevent pipe blockages and enhance filling efficiency, the flow velocity must exceed the critical value. During the filling process, it’s essential to reasonably determine the size of the critical flow velocity based on factors such as the slurry mixture ratio, pipeline diameter, and filling multiplication factor. Additionally, necessary measures—such as adding water-reducing agents or optimizing pipeline design—should be implemented to improve the fluidity of the filling slurry, ensuring that the flow velocity remains above the critical threshold.

Hydraulic Gradient

Hydraulic gradient refers to the frictional resistance that the slurry must overcome as it flows through the pipeline, as well as the interlayer resistance caused by turbulence within the slurry. It is one of the critical factors that must be considered when performing calculations for filling systems. During the filling process, the appropriate size of the hydraulic gradient needs to be determined based on the actual conditions of the filling system and the specific mining requirements. Additionally, the issue of pressure reduction in deep-well filling must also be taken into account; the location and magnitude of pressure relief should be carefully decided according to the hydraulic gradient, ensuring both the stability and safety of the filling system.

Slump and Slump Flow

Slump and slump flow are indicators used to evaluate the flow properties of filling slurries. They reflect how smoothly the slurry flows under its own weight and external forces, as well as the ease with which it can be pumped into the mining stope during backfilling operations. During the filling process, it is essential to conduct experiments to measure the slump and slump flow of the filling slurry, and based on these results, adjust the mix proportions and delivery parameters to ensure the quality and stability of the backfilled material. At the same time, it’s also necessary to consider the varying requirements for slump and slump flow across different filling systems, in order to optimize the overall performance of the backfill body.

IV. Conclusion

In summary, the physical and mechanical properties of the filling material, the mix proportions of the filling slurry, and the flow characteristics of the slurry are key factors influencing both the quality of the backfill body and mining efficiency. In fill-based mining operations, it is essential to rationally determine the appropriate values and ranges for these parameters based on the specific conditions of the mine and the requirements of the mining process. At the same time, proactive measures must be implemented to optimize the performance of the backfill body, thereby enhancing both mining efficiency and safety. For instance, backfill quality and stability can be improved by fine-tuning the slurry mix ratio, upgrading the delivery system, and reinforcing monitoring and maintenance of the backfill body. Moreover, continuous learning and research into new advancements and innovative approaches in filling theory and technology are crucial for driving ongoing innovation and development in this field.