Core Concepts and Technical Features of the Ramp Development Method – HeijinGang Report

Core Concepts and Technical Features of the Ramp Development Method

Basic Concepts and System Architecture

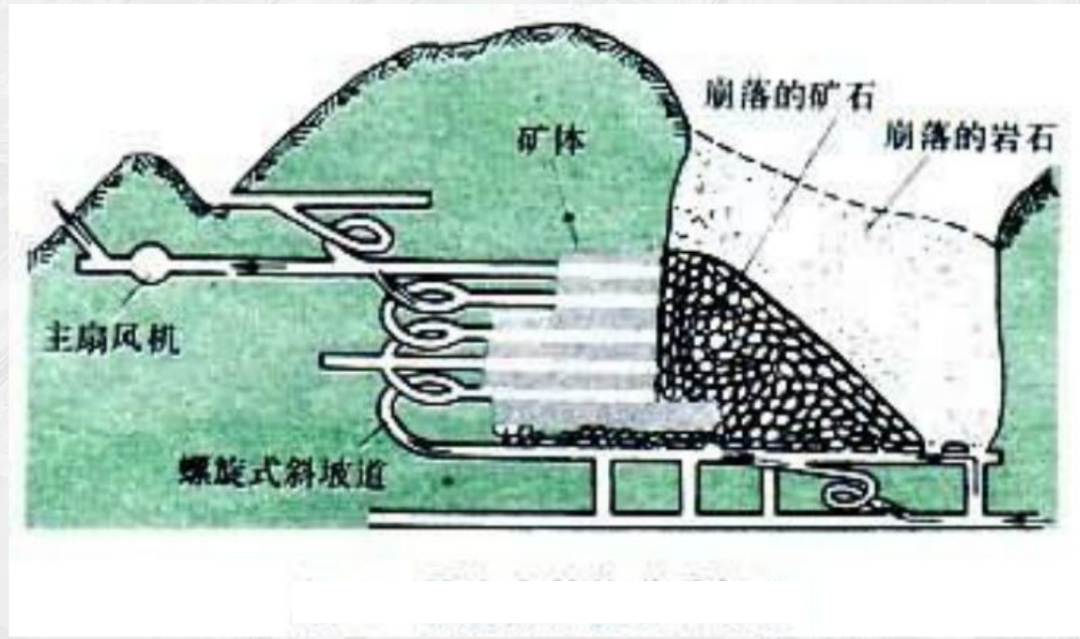

The ramp development method is an underground mining technique that utilizes inclined roadways (ramps) to establish a connected system linking surface and various underground mining levels. In modern mining engineering, with the widespread adoption of trackless mining equipment, the ramp development method has gradually emerged as a crucial approach due to its unique advantages. At its core, this method provides direct access for trackless mining vehicles—such as loaders, trucks, and drilling rigs—enabling them to move seamlessly from the surface into the mine or between different intermediate levels. This significantly enhances the efficiency and flexibility of mining operations.

The system typically includes a main ramp and an auxiliary ramp. The main ramp serves as the critical link between the surface and the primary transportation level, handling the bulk of transport tasks—such as moving ore, waste rock, and delivering equipment and materials. Meanwhile, the auxiliary ramp is primarily used for connecting different intermediate levels, facilitating the movement of personnel and equipment between these sections, while also supporting the transportation of smaller supplies when needed.

Based on their geometric form, ramps can be divided into two types: open ramps and blind ramps. Open ramps have direct surface openings that connect directly to the surface industrial site, offering the advantage of relatively simple construction and easy access for equipment and materials. In contrast, blind ramps open underground without direct connection to the surface, typically used in specific mining layouts or under particular geological conditions—such as when extracting deep-seated ore bodies or when it’s necessary to avoid complex surface topography.

(II) Key Technical Features

Environmental Adaptability Advantage :The ramp development method faces fewer limitations imposed by topography, surface industrial site layouts, and geological conditions. Compared to the adit development method, which requires favorable terrain—such as the ore body being located on one side of a mountain with sufficient elevation difference for adit placement—the ramp method can be implemented in virtually any environment—whether in mountainous, hilly, or even flat regions—as long as the underlying geology permits. In particularly rugged mountainous areas, ramps can be designed to follow the natural contours of the land, seamlessly connecting surface workings with underground ore bodies. In contrast, shaft development often encounters significant challenges due to steep terrain and fractured rock formations, making it difficult to determine the optimal shaft location and increasing construction complexity. Additionally, ramps place relatively lower demands on surface industrial sites, eliminating the need for vast, leveled areas typically required for shaft development to accommodate hoisting equipment and surface structures.

Limited depth sensitivity When the mining depth exceeds 200 meters, the transportation costs associated with the ramp development method will increase significantly. This is mainly due to the fact that trackless equipment experiences a substantial rise in fuel consumption when operating over long distances with steep gradients on ramps. Additionally, tire wear on trackless equipment intensifies, necessitating more frequent tire replacements, which further drives up operational expenses. Moreover, maintenance costs for trackless equipment tend to be relatively high; as mining depth increases, equipment failure rates may climb, leading to greater repair challenges and higher overall costs. In contrast, rail-based or conveyor belt systems prove more economically viable in deep-mining operations, enabling efficient transportation of large volumes of ore at lower costs.

Engineering Quantity Comparison Features At the same mining depth, the engineering workload for a ramp is 3 to 6 times greater than that of a shaft development. This is because ramps must meet specific slope requirements to accommodate trackless equipment, typically limiting the gradient to no more than 30%. As a result, the horizontal projection distance of a ramp becomes significantly longer than the vertical lifting height. For instance, if developing a mineral deposit at a depth of 500 meters, a vertical shaft would have a shaft depth of exactly 500 meters. However, if a ramp is used instead—with a slope of 15%—the ramp’s total length could easily exceed 3,000 meters, not to mention the additional space required for equipment turning and passing each other, as well as the extra engineering work involved in widening roadways and constructing auxiliary tunnels. Such an enormous construction volume not only drives up capital costs but also extends the project timeline, profoundly impacting both the mine’s initial investment and overall development schedule.

Slope Roadway Development Method: Main Layout Plans and Engineering Characteristics

In mine exploitation, the selection of an appropriate ramp development scheme is crucial, as it directly impacts the efficiency, cost, and safety of mining operations. Depending on varying geological conditions, orebody characteristics, and specific extraction requirements, several ramp development schemes have emerged. Among these, the straight, return, and spiral ramp types are the most common and representative. Each of these three schemes differs in terms of structural design, applicable conditions, and engineering features. Therefore, mining enterprises must carefully evaluate multiple factors and make a scientifically sound decision when choosing the optimal ramp layout to ensure efficient and safe mining operations.

Straight-line ramp: A concise and efficient shallow-ore development solution

Layout Features and Technical Parameters

The straight-line ramp is an extremely simple and efficient method for developing mine accessways. From the ramp entrance to its base, the path forms a perfectly straight line with no curves along the way. This straightforward design allows vehicles to maintain a relatively stable speed and consistent direction throughout their journey, significantly simplifying driving operations. However, the ramp’s slope is strictly limited by the climbing capability of the trackless equipment used. Typically, the gradient is kept within the 8% to 15% range. If the slope exceeds this limit, the equipment may struggle to ascend, potentially leading to safety hazards. Conversely, if the slope is too gentle, it would unnecessarily extend the length of the ramp, thereby increasing construction costs and complicating the project’s execution. In a real-world engineering case, a mining operation successfully implemented the straight-line ramp approach by precisely setting the ramp’s incline at 12%, based on the specific climbing capacity of the trackless equipment being utilized. This careful adjustment ensured smooth equipment operation and optimized transportation efficiency.

In terms of spatial relationships, the opening position of the straight ramp must be carefully planned to ensure a direct alignment with the shallow level of the orebody. This is essential because only in this way can long-distance drift development during mining operations be avoided, thereby reducing both the overall engineering workload and construction costs. If the opening position is chosen improperly, resulting in a significant distance between the ramp and the shallow level of the orebody, additional drifts will need to be excavated to connect the two—increasing not only the complexity and duration of construction but also raising expenses related to ventilation, drainage, and other critical systems. During the planning phase, it is crucial to identify the optimal opening location through detailed geological exploration and precise measurements, ensuring an efficient and seamless connection between the ramp and the shallow level of the orebody.

Applicable Conditions and Engineering Limitations

The straight-type ramp is primarily suited for specific mining scenarios. When the orebody is buried relatively shallow—typically at depths of less than 200 meters—and dips gently, with an inclination angle below 30°, the straight-type ramp can fully leverage its advantages. In such cases, it enables a direct and efficient connection between the surface and the orebody, facilitating rapid access for trackless equipment and ensuring smooth transportation of mined materials. Additionally, it is often employed as an auxiliary connecting roadway between different mining stages, making it easier for personnel and equipment to move between phases, while also simplifying the logistics of material transport.

Straight-line ramps have significant limitations in deep-mining operations. As the depth of the orebody increases, the length of the ramp grows rapidly. When the depth becomes substantial, long-distance ramps dramatically raise the difficulty of ventilation, driving up ventilation costs to unprecedented levels. To maintain air quality and ensure effective ventilation within the ramp, it may become necessary to install high-powered ventilation equipment and deploy complex ventilation duct systems. Meanwhile, drainage issues also become more challenging—longer ramps require even more sophisticated drainage facilities to guarantee that accumulated water is promptly removed, preventing potential disruptions to equipment operation and ensuring the safety of personnel. Additionally, straight-line ramps place stringent demands on the stability of surrounding rock formations. If fault zones or areas with poor rock integrity exist in the construction zone, the ramp is prone to deformation or even collapse during prolonged mining activities, posing serious risks to mine safety and jeopardizing the smooth operation of the entire mining process.

Key Points for Engineering Applications

In engineering applications, ensuring the safe and stable operation of straight inclined ramps requires attention to several key points. Prioritizing excavation in areas with hard surrounding rock is crucial, as sturdy rock formations provide excellent support for the ramp, significantly reducing the risk of roadway deformation and collapse. During the excavation process, additional support measures can be implemented, such as anchor bolt reinforcement or shotcrete lining, further enhancing the stability of the tunnel. For long-distance straight inclined ramps, ventilation remains a critical issue that must be addressed. Local ventilation fans are commonly used as essential equipment to deliver fresh air efficiently throughout the ramp, ensuring adequate airflow for workers' breathing needs and maintaining optimal operating conditions for machinery. Moreover, the condition of the road surface plays a vital role in the safety and efficiency of trackless equipment operations. Adopting a concrete-paved surface not only boosts the pavement's strength and wear resistance but also minimizes vibrations and wear during equipment movement. Additionally, incorporating anti-slip grooves into the road surface is an indispensable measure, as it effectively reduces the risk of skidding—especially in wet or water-logged conditions—by dramatically increasing friction between tires and the road, thereby guaranteeing safer equipment operation.

Return-style Ramp: A Flexible Adaptation Solution for Complex Terrain

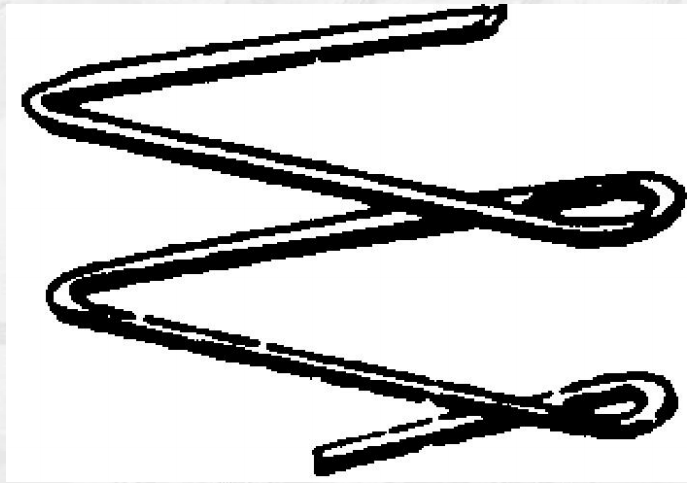

Structural Design and Operating Principles

The structural design of the return-type ramp is quite unique, as it alternates between straight and reversing sections, creating an approach tailored to complex terrain and orebody conditions. The straight segments primarily handle elevation changes throughout the ramp, with gradients typically maintained between 10% and 15%. This gradient range ensures that trackless equipment can smoothly ascend or descend while maintaining operational safety and efficiency—avoiding the risks associated with excessively steep slopes. In practice, trackless vehicles travel at relatively stable speeds along the straight sections, seamlessly bridging the height differences between various levels.

The turnaround section is primarily used to facilitate directional changes. Its slope is typically designed to be relatively gentle—often level or gently inclined—with a gradient no greater than 5%. This gentle slope ensures that trackless equipment can safely and smoothly complete its turn without compromising stability. At the turnaround section, equipment must slow down and proceed cautiously to accommodate the turning maneuver. To further enhance the transportation of both ore and waste rock, stage gateways are usually excavated within this section. These gateways lead directly into the stage-level transport drifts, creating an efficient transportation network that enables ore and waste rock to be swiftly and conveniently moved from the mining area to the main transport corridors.

To address the muck removal challenges during tunneling and meet ventilation needs during operation, the turnaround section can also be equipped with dedicated service shafts tailored to specific site conditions. These service shafts can serve as ventilation shafts, providing optimal airflow throughout the ramp and ensuring that air quality in the working environment meets safety standards. Alternatively, they can function as discharge chutes, enabling rapid removal of waste materials generated during excavation and significantly boosting construction efficiency. In several mining projects involving the construction of reversible ramps, strategically incorporating ventilation and discharge shafts into the turnaround sections has effectively resolved both ventilation and muck-handling issues, thereby maintaining smooth and uninterrupted mine operations.

Applicable Conditions and Technical Advantages

The return-type ramp boasts a wide range of applications, particularly well-suited for mining medium-to-deep ore bodies—typically at depths between 200 and 500 meters. In areas characterized by significant topographic fluctuations, the return-type ramp also demonstrates its unique advantages. Under these complex geological and topographical conditions, the ramp can cleverly navigate around unfavorable geological features such as faults and fracture zones by flexibly adjusting the location of turning points and fine-tuning the lengths and gradients of both straight and curved sections. This ensures the safe and smooth progression of development projects. In mountainous mining operations, where terrain is often intricate and ever-changing—with numerous undulating landscapes and regions plagued by unstable geological conditions—the return-type ramp can be custom-designed to precisely match the specific topography and geology on site, effectively bypassing hazardous areas and enabling highly efficient ore-body development.

In terms of safety, the reversing ramp offers distinct advantages. The straight sections provide excellent visibility, allowing drivers to clearly observe road conditions ahead and react promptly, thereby reducing the risk of traffic accidents caused by obstructed views. Meanwhile, the gentle design of the reversing section ensures smooth transitions as vehicles navigate the turn, significantly lowering the likelihood of rollovers or collisions. Additionally, pavement maintenance is relatively convenient—thanks to the structural features of the reversing ramp, the roadway can be divided into separate segments for targeted upkeep and repairs, enhancing both the efficiency and precision of maintenance operations.

Key Parameters for Engineering Design

In engineering design, several key parameters of a reversible ramp need to be precisely determined. The length of a single straight segment is generally recommended to not exceed 300 meters. This is because excessively long straight sections may cause visual fatigue for drivers during operation, thereby increasing safety risks. Additionally, longer straight segments become more challenging to adjust when encountering changes in geological conditions. The width of the turnaround section must carefully account for the turning radius required by the equipment—particularly for large trucks, where the turnaround width typically needs to be at least 15 meters or more—to ensure that vehicles can smoothly complete their turning maneuvers.

The angle between the stage gate and the main ramp is also an important parameter, typically maintained between 60° and 90°. This angular range ensures maximum transportation efficiency. If the angle is too small, it can lead to inefficient flow along the transport route, slowing down the movement of ore and materials; conversely, if the angle is too large, it will increase the excavation workload and construction complexity of the gate itself. In the actual design process, these critical parameters must be carefully evaluated and precisely determined based on specific equipment types, transportation requirements, and geological conditions, ultimately enabling the optimal design of a return-type ramp.

Spiral Ramp: A Compact Exploration Solution for Deep Space

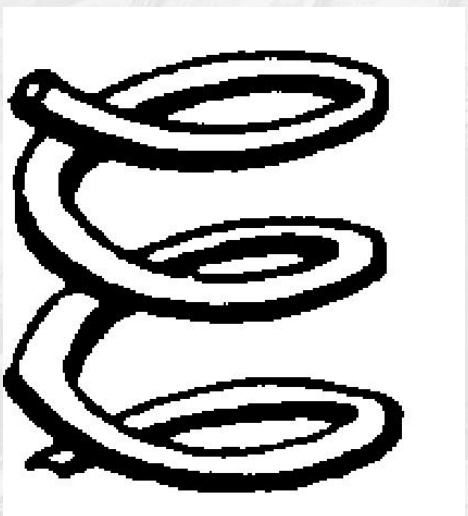

Geometric Forms and Construction Requirements

The geometry of a spiral ramp typically takes the form of either a cylindrical helix or a conical helix. This unique spatial trajectory allows it to achieve significant vertical height changes within relatively compact spaces, providing an efficient method for developing deep mineral deposits. The ramp’s slope generally ranges between 10% and 30%, and compared to other types of ramps, the spiral ramp offers greater flexibility in adjusting its incline to suit varying mining conditions.

During construction, the spiral ramp must work in coordination with the central ore chute or vertical shaft—this is crucial for ensuring smooth excavation, muck removal, and ventilation. The central ore chute efficiently discharges the large volumes of waste generated during excavation, significantly boosting construction efficiency. Meanwhile, the vertical shaft serves as a vital ventilation channel, providing optimal airflow throughout the entire ramp and safeguarding both workers' safety and equipment performance. Since the spiral ramp follows a helical path, its curvature radius typically needs to be no less than 20 meters to ensure vehicles can navigate safely and smoothly. Under these complex route conditions, highly precise surveying and control technologies must be employed during excavation to guarantee that the ramp’s alignment meets design specifications, preventing issues like track deviation. Additionally, to enhance driving safety, reflective mirrors, speed limit signs, and other safety features should be installed along the ramp, reminding drivers to stay alert and maintain caution while operating their vehicles.

Application Scenarios and Economic Analysis

The spiral ramp is particularly well-suited for developing deep-seated ore bodies, and its advantages become especially pronounced when the depth of the ore body exceeds 500 meters. In deep-mining operations, where space resources are limited, the spiral ramp excels by enabling a compact layout that significantly saves space and reduces the overall footprint. Compared to return-type ramps, the spiral ramp offers a substantial advantage in terms of engineering effort, cutting excavation work by 20% to 25%. This not only shortens the construction timeline but also lowers capital costs, ultimately boosting the mine's economic efficiency. In fact, in several deep-mine projects, adopting the spiral ramp development method has successfully minimized excavation requirements, allowing for an earlier-than-planned production start-up—and delivering remarkable financial benefits to the companies involved.

The spiral ramp also has certain limitations. Since vehicles must continuously turn while traveling on the spiral ramp, the wear rate of the equipment tires is about 30% higher compared to a reversing-type ramp. This necessitates regular tire replacements, thereby increasing operational costs. Additionally, to ensure adequate ventilation within the ramp, high-powered fans must be installed to overcome the significant resistance encountered over its long length—resulting in higher energy consumption and further boosting operational expenses.

Engineering Optimization Measures

To further enhance the engineering performance and safety of spiral ramps, a series of optimization measures can be implemented. In terms of construction sequencing, adopting the approach of "excavating vertical shafts before ramp tunnels" proves to be an effective strategy. By first creating vertical shafts and leveraging them to establish ventilation loops, any subsequent excavation of the ramp tunnels can proceed smoothly, ensuring efficient ventilation while significantly improving both construction efficiency and safety. Additionally, incorporating a gradually increasing superelevation on the spiral sections is another crucial optimization step. By raising the outer edge of the road surface by 2% to 5%, vehicles experience an inward centripetal force during turns, which greatly enhances their stability and reduces the likelihood of rollovers or other accidents. The combined application of these optimization measures will markedly elevate the engineering quality and operational safety of spiral ramps, providing robust support for the efficient extraction of deep-seated mineral resources.

Applicable Conditions and Selection Principles for the Ramp Development Method

In the field of mine exploitation, the successful application of the ramp development method hinges on precisely identifying suitable conditions and rigorously adhering to the principles guiding scheme selection. This not only affects mining efficiency and costs but is also closely tied to the safe production and sustainable development of the mine. Diverse orebody characteristics, engineering and economic requirements, as well as safety and environmental protection standards, all pose unique challenges and demands for the practical implementation of the ramp development approach.

In the field of mine exploitation, the successful application of the ramp development method hinges on precisely identifying suitable conditions and rigorously adhering to the principles guiding scheme selection. This not only affects mining efficiency and costs but is also closely tied to the safe production and sustainable development of the mine. Diverse orebody characteristics, engineering and economic requirements, as well as safety and environmental protection standards, all pose unique challenges and demands for the practical implementation of the ramp development approach.

(1) Suitability of Ore Body Occurrence Conditions

Burial Depth The burial depth of the ore body is one of the key factors in selecting a ramp development scheme. For shallow ore bodies—those buried less than 200 meters deep—straight ramps offer a distinct advantage. Their simple, linear structure makes construction relatively easier and allows for rapid connectivity between the surface and the ore body, thereby reducing initial construction costs. In some smaller mines where ore bodies are located closer to the surface, adopting straight ramps can complete the development work in a shorter timeframe, enabling swift entry into production. When the ore body lies at intermediate to deeper levels—ranging from 200 to 500 meters—the return-type ramp becomes the preferred choice. By cleverly combining straight and return sections, this type of ramp better meets the mining requirements of mid-to-deep-level deposits. Not only does it facilitate efficient elevation and directional changes, but it also helps keep engineering costs and construction complexity under control. For deep ore bodies—those exceeding 500 meters in depth—a combined approach featuring spiral ramps and vertical shafts is more suitable. Although spiral ramps present greater excavation challenges, they offer unique advantages in maximizing space utilization at great depths, allowing for significant vertical height variations within confined areas. Meanwhile, the vertical shaft takes on the primary role of material hoisting, boosting transportation efficiency. Together, these two methods enable highly effective extraction of deep-seated mineral resources.

Mineral body dip The dip angle of the ore body also significantly influences the selection of ramp development schemes. For gently inclined ore bodies—where the dip angle is less than 30°—a straight ramp can be a highly suitable match. The gentle inclination allows the straight ramp to directly connect the surface with the ore body, facilitating easy access for trackless equipment and efficient transportation of ore. For moderately inclined ore bodies, with dip angles ranging between 30° and 60°, a switchback ramp proves more advantageous. With its flexible route design, the switchback ramp can effectively link the ore body at various elevations and orientations, perfectly meeting the mining requirements of moderately inclined deposits. Finally, for steeply inclined ore bodies—where the dip angle exceeds 60°—a combination of a spiral ramp and a chute system emerges as the ideal choice. The spiral ramp provides a viable passage for trackless equipment, while the chute system leverages the ore body’s steep incline to enable rapid, gravity-fed ore transport, thereby enhancing overall operational efficiency.

(II) Engineering Economic Analysis

Initial investment In terms of initial investment, there are significant differences among various types of ramps. Spiral ramps, due to their complex geometry and higher construction challenges, require greater investments in manpower, materials, and financial resources. During the excavation process, highly precise measuring equipment and advanced construction techniques must be employed to ensure that the ramp’s alignment meets design specifications—undoubtedly driving up construction costs. Moreover, to guarantee the stability and safety of spiral ramps, even more intricate support designs and construction methods are needed, further inflating the overall investment. In contrast, reversible ramps have relatively moderate initial investments. While they still demand certain technical expertise and equipment support, their construction complexity and reinforcement requirements are comparatively lower. Meanwhile, straight ramps boast the lowest initial investment, thanks to their straightforward design, which simplifies the construction process and reduces both the amount of required equipment and materials, thereby lowering overall costs.

Operating Costs As the mining depth increases, the operational costs of ramps also change. Spiral ramps, with their compact track layouts, allow vehicles to minimize unnecessary travel distances during operation, thereby reducing fuel consumption and equipment wear. Compared to reversing ramps, spiral ramps exhibit a relatively smaller increase in transportation costs when used in deep-mining operations. In contrast, reversing ramps, due to their numerous reversing sections, require vehicles to frequently decelerate, accelerate, and make sharp turns—processes that not only boost fuel consumption but also accelerate equipment wear, leading to higher overall operating costs. In practical operations, a certain mine found that adopting spiral ramps for deep-mining transportation reduced costs by approximately 15% compared to reversing ramps, clearly demonstrating the cost advantages of spiral ramps in deep-extraction scenarios.

(III) Safety and Environmental Protection Technical Requirements

Follow safety standards All ramp development plans must strictly adhere to the relevant provisions of the "Safety Regulations for Metal and Non-Metallic Mines." Regarding roadway clearance, to ensure safe passage of trackless equipment, the clear height of the roadway must meet or exceed the equipment’s height plus a safety clearance of 0.6 meters. As for slope requirements, the gradient of ramps used by trackless vehicles should generally not exceed 15%; under special operational conditions, however, the slope may still be limited to no more than 30% to prevent accidents such as skidding or loss of control during vehicle movement. Additionally, ventilation velocity is another critical safety parameter—within ramps, the airspeed must remain at or above 0.5 m/s to maintain adequate ventilation, effectively removing harmful gases and providing workers with a safe and healthy working environment.

Implementation of environmental protection measures In terms of environmental protection, prioritizing the use of electric trolleybuses or hydrogen-fueled equipment is a crucial measure to reduce exhaust emissions within ramps. These devices produce virtually no harmful gases during operation, significantly improving the underground working environment. To further minimize the environmental impact of exhaust emissions, it’s also essential to install accompanying exhaust purification systems that treat and clean the gases emitted by the equipment. Additionally, an automatic water-spraying dust suppression system is an indispensable eco-friendly facility—it can regularly spray water throughout the ramp area, effectively lowering dust concentrations and mitigating the health risks posed to workers. At the same time, this system helps reduce dust-related wear and tear on equipment, thereby extending the lifespan of the machinery.

Typical Engineering Cases and Technological Innovations

Shallow open-pit to underground mining: Rapid connection via a straight ramp

During the mining process at a certain copper mine, the operation underwent a transformation—from shallow open-pit mining to deep underground extraction. Initially, the shallower ore bodies were mined using open-pit methods. As mining progressed deeper, extracting the deeper deposits became the next priority. To ensure a smooth transition between these two methods, the mine carefully constructed a straight ramp with a 12% gradient along the ore body's strike. This ramp serves as a rapid, direct link between the surface and the underground, enabling trackless equipment to swiftly move from the surface to the first underground level within just 72 hours. Compared to the conventional vertical shaft development approach, this straight ramp method has demonstrated distinct advantages, successfully reducing the overall construction period by as much as six months.

During the earlier stage of open-pit mining, this copper mine had already accumulated extensive experience in surface extraction. However, as the ore body gradually extended deeper underground, the limitations of open-pit mining became increasingly apparent. While the traditional shaft development method does offer certain advantages in deep-mining operations—such as efficient access to lower levels—it suffers from lengthy construction periods and high costs, making it unable to meet the urgent need for a rapid transformation at this copper mine. After a comprehensive evaluation, the straight-line ramp development method emerged as the optimal choice, thanks to its relatively simple construction process and its ability to quickly connect surface and underground workings.

During the construction process, the technical team at the copper mine overcame numerous challenges. Through precise geological exploration, they accurately determined the orientation and location of the ore body, providing a scientific basis for the layout of the ramp. In the excavation of the ramp, advanced tunneling equipment and innovative support technologies were employed to ensure both the stability and safety of the structure. To meet the operational needs of trackless equipment, strict controls were implemented on the ramp’s slope, width, and road surface conditions, guaranteeing that machinery could travel safely and efficiently.

Through the seamless integration of a straight-line ramp, this copper mine successfully transitioned from open-pit to underground mining, not only boosting mining efficiency but also cutting production costs. This successful case provides valuable lessons and practical insights for other mines as they explore options for shifting from open-pit to underground operations.

Medium-to-Deep Complex Orebody: Reversing Ramp to Mitigate Geological Risks

The mining operation at a certain gold mine, located in the 200–400m mid-level section, faces complex geological conditions. The orebody crosses three fault zones, posing significant challenges to the development project. To tackle this intricate situation, the gold mine has adopted a "three straight and two folded" return-type ramp design. During the planning phase, engineers carefully considered the location and orientation of the fault zones, ingeniously incorporating horizontal return sections precisely at these fault zones. These horizontal return segments not only provide ample space for equipment turning but also help absorb and distribute stress, effectively mitigating the impact of the fault zones on ramp stability.

To further ensure the stability of the ramp under complex geological conditions, the gold mine has adopted enhanced anchor-net-cable support technology in the reversing section. By driving anchors into the tunnel walls, laying metal mesh, and applying prestress to the anchor cables, a robust support system has been established, significantly enhancing the strength and stability of the surrounding rock. Throughout the construction process, operations were carried out strictly according to design specifications, ensuring the quality and effectiveness of the support system.

After practical operation verification, the return-type ramp design has achieved remarkable results. It successfully avoided fractured rock layers and effectively controlled roadway deformation to within 50 mm, ensuring safe and efficient mining operations. In daily production, equipment can smoothly traverse the ramp, and ore transportation remains uninterrupted—no production disruptions have occurred due to roadway deformation or challenging geological conditions. This case clearly demonstrates the exceptional adaptability and reliability of the return-type ramp when tackling complex, medium-to-deep mineral deposits, providing valuable insights for mine development under similar geological conditions.

Deep-vein hard-rock mine: Intelligent Construction of Spiral Rampways

In an iron mine operating at a depth of 600 meters, a bold decision was made to implement a spiral ramp system, accompanied by the introduction of a series of advanced, intelligent construction technologies. During the project, the 3D laser scanning guidance system played a critical role. By continuously scanning the construction site in real time and comparing the captured data with the design model, the system precisely directs the excavation process, ensuring that the ramp’s deviation remains within ±20mm. This highly accurate guidance technology has significantly enhanced construction quality while minimizing rework and resource waste caused by excavation inaccuracies.

The application of concrete spraying robots has also brought revolutionary changes to the construction of spiral ramps. Traditional concrete spraying operations rely heavily on manual labor, often resulting in inconsistent quality and difficulty in meeting precision requirements. In contrast, concrete spraying robots can automatically carry out the spraying process according to pre-set parameters, significantly boosting construction efficiency while ensuring consistent spray thickness and uniformity. This not only enhances the support quality of the ramps but also reduces the amount of time workers spend in harsh, hazardous environments, thereby improving both safety and overall project outcomes.

By integrating the intelligent ventilation system, this iron mine has achieved on-demand air supply. The smart ventilation system continuously monitors air quality, temperature, humidity, and other parameters within the ramp, automatically adjusting fan speed and airflow to ensure that the air quality at the working face meets or exceeds 98% compliance standards. This provides workers with a fresh, safe, and healthy work environment, effectively reducing the risk of occupational diseases and significantly boosting productivity.

Through the comprehensive application of these intelligent construction technologies, the spiral ramp at this iron mine has achieved remarkable results. Not only has construction efficiency and quality been improved, but costs and safety risks have also been reduced, offering a brand-new technological model and direction for the mining of deep, hard-rock mines.

Summary

The ramp development method holds a unique position and plays a vital role in modern mining engineering. With its flexible layout and adaptability to various orebody conditions, it provides mines with efficient and convenient access routes for extraction. The straight-type ramp is ideal for shallow orebodies, offering advantages such as simple construction and rapid connection. Meanwhile, the return-style ramp excels in the extraction of complex, medium-to-deep-level ore bodies, effectively mitigating geological risks. Lastly, the spiral-type ramp proves indispensable in deep-level orebody development, where the application of advanced intelligent construction technologies has significantly enhanced both efficiency and quality.