Major Development Roadway Type Comparison and Analysis – Heijinggang Broadcast

Comparative Analysis of Main Roadway Development Types

Technical and Economic Differences Between Adits and Shafts

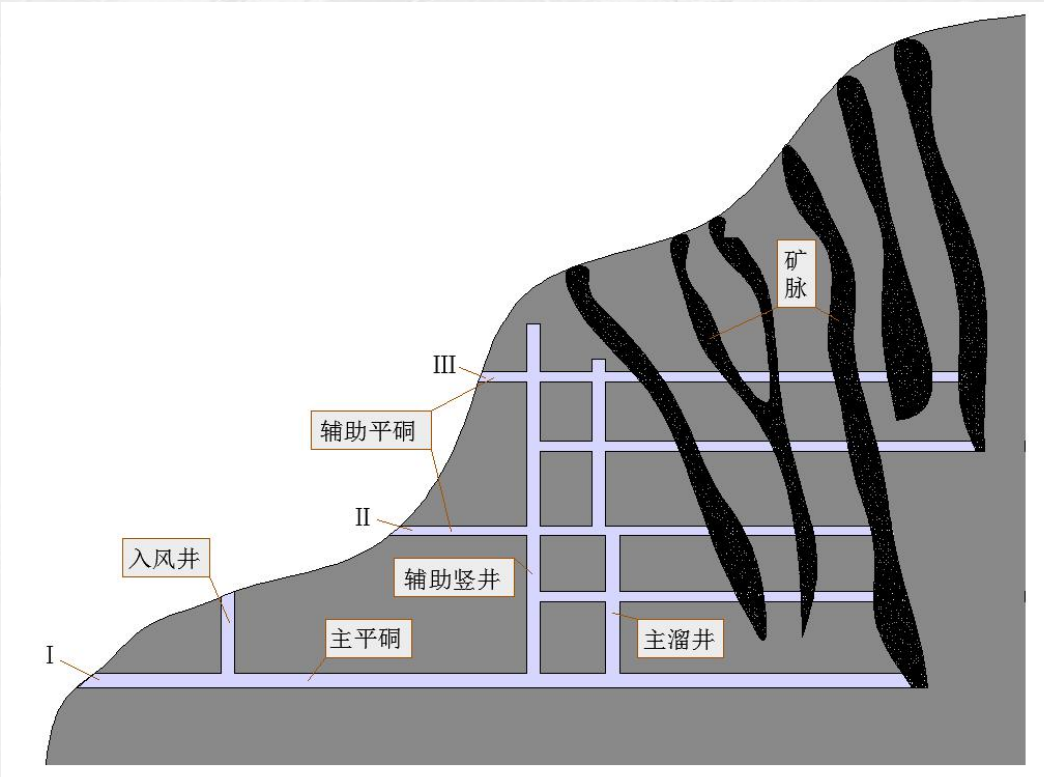

As a horizontal tunnel directly connecting the surface to the ore body, the adit demonstrates significant advantages during the infrastructure phase. Its construction process is straightforward, eliminating the need for complex shaft hoisting equipment and associated facilities at the wellhead. As a result, adit construction is 30%–50% faster than shaft-based methods, shortening the overall infrastructure period by more than 40%. From a cost perspective, the adit’s excavation cost per unit length is only one-third to one-half that of a vertical shaft, and it also avoids the need for structures like derricks or hoisting machine rooms, reducing initial investment by up to 60%. In production and operation, the adit leverages gravity for self-flowing drainage and natural ventilation. For transportation, it relies on motorized locomotives or belt conveyors, which cut energy consumption costs by over 50% compared to traditional shaft-based systems. Additionally, adit maintenance costs are minimal, and its accident rate is just one-fifth that of shaft systems, making it exceptionally safe and reliable.

Level adit

A Multi-Dimensional Comparison of Vertical and Inclined Shafts

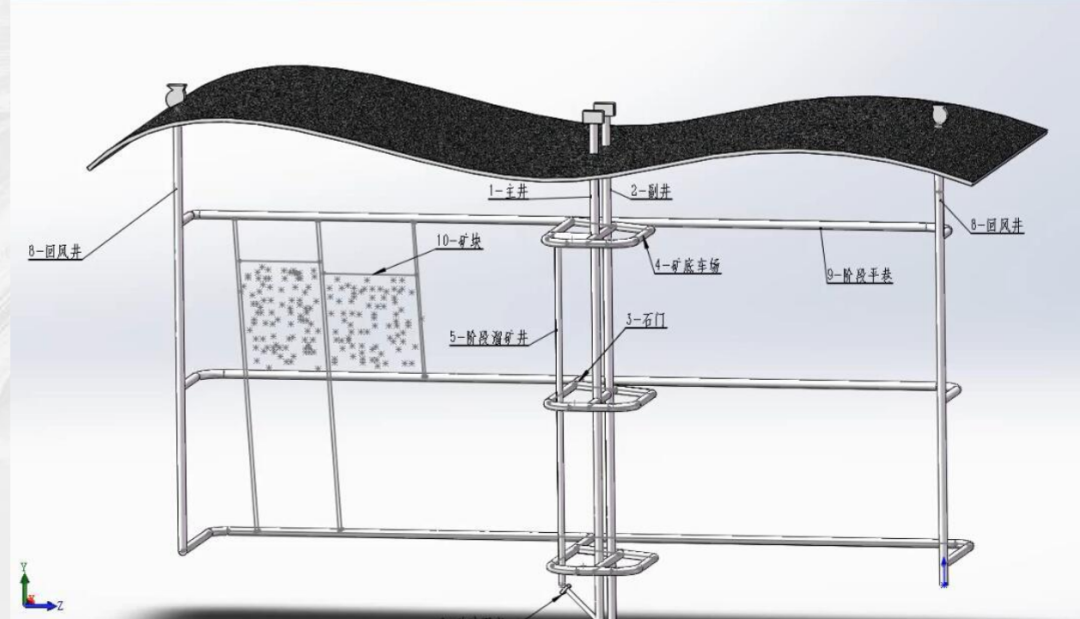

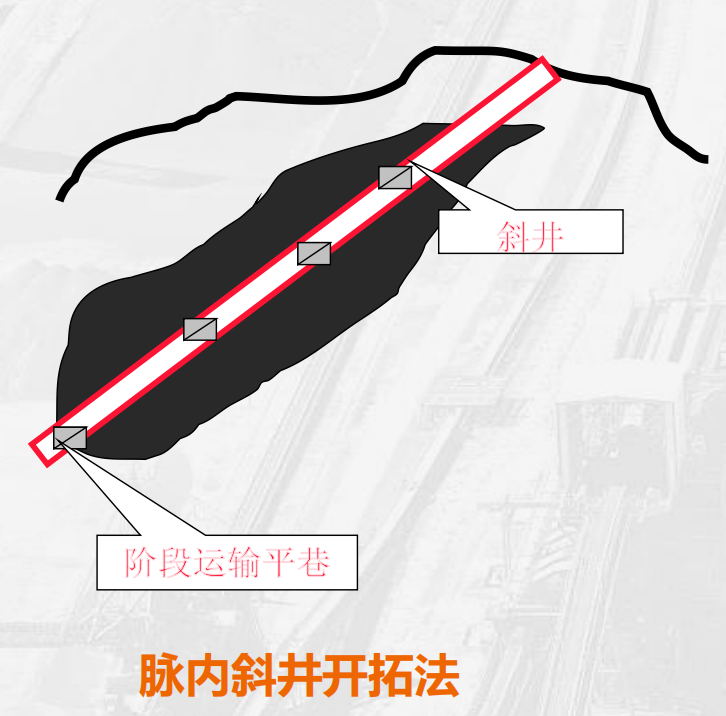

In terms of infrastructure construction volume, although inclined shafts are longer in length, their per-unit-length construction costs are 20% to 30% lower than those of vertical shafts, and the underground yard structures at their bottoms are simpler. In contrast, vertical shafts require the construction of complex underground yards and longer adits, resulting in a significantly larger initial workload. When it comes to shaft equipment, vertical shafts necessitate the installation of multi-level cage systems, balancing devices, and other sophisticated hoisting mechanisms. Meanwhile, inclined shafts encounter challenges such as lengthy pipeline installations and high-lift requirements for drainage equipment, leading to inclined shaft drainage costs that are 15% to 20% higher than those of vertical shafts. In terms of pressure resistance, vertical shafts, with their vertically oriented structural design, exhibit compressive strength that is 30% to 40% greater than inclined shafts, making them well-suited for deep-mining areas characterized by high in-situ stress. Regarding production capacity, vertical shafts can achieve hoisting speeds of 8 to 12 meters per second, enabling each shaft to handle over 5 million tons of material annually. In contrast, inclined shafts are limited by steel cable wear and the steep lifting angle, resulting in higher maintenance costs and a lower overall production capacity ceiling. Finally, in terms of construction difficulty, inclined shafts boast a mechanization rate of up to 70%, delivering 25% higher construction efficiency compared to vertical shafts. However, vertical shafts are better positioned for fully automated, end-to-end mechanized operations.

Shaft

Inclined shaft

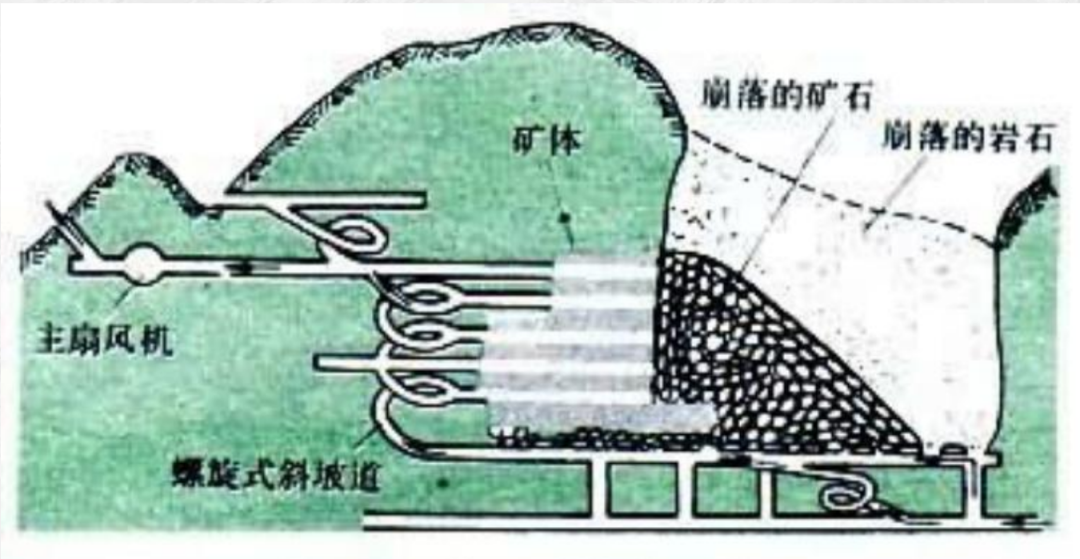

Comparison of Suitability Between Ramp and Shaft

The ramp features broad geological adaptability, allowing it to traverse a variety of complex rock formations. Construction is 40% faster than shaft-based systems, enabling the rapid establishment of an underground transportation network. Its open design facilitates easy passage for trackless equipment, while mechanized operations achieve an efficiency rate of over 90%, significantly boosting material-handling productivity. However, when diesel-powered equipment is used, a robust ventilation system must be installed to manage exhaust emissions, increasing ventilation costs by 20% to 30% compared to shaft systems. In contrast, shaft systems offer superior stability in deep-level ventilation and high-pressure environments, making them more suitable for deep mines. Meanwhile, ramps are better suited for medium-to-shallow-depth mines where quick, highly mechanized operations are prioritized.

The Core Principles for Exploring Solution Options

Safety and Environmental Protection First Principle

Safety is the cornerstone of mine production. In the design of development plans, it is essential to strictly adhere to safety regulations, ensuring that at least two independent safety exits are established—each spaced no less than 30 meters apart—to prevent situations where a single exit becomes blocked due to accidents, leaving personnel unable to evacuate safely. Additionally, the clear cross-sectional area of each exit passage must be at least 6 square meters, allowing people and equipment to move swiftly and smoothly, thereby meeting the high-volume demands during emergency evacuations. When determining the location of primary development roadways, thorough consideration must be given to geological conditions. Advanced geotechnical exploration techniques, such as 3D seismic surveys and transient electromagnetic methods, should be employed to precisely identify areas prone to geological hazards—like fault fracture zones and karst-developed regions—ensuring these dangerous areas are carefully avoided during roadway layout, thus minimizing safety risks caused by potential geological disasters.

Meanwhile, leveraging numerical simulation software such as FLAC3D and ANSYS, we conduct in-depth analyses of rock strata movement patterns, enabling accurate predictions of surface settlement and deformation at various stages of mining. To ensure the safety of industrial facilities, the site is strategically located more than 20 meters away from the expected ground movement zone, thereby preventing potential damage to buildings and infrastructure caused by mining activities. As a critical component for maintaining underground air quality, the ventilation system must undergo rigorous scientific calculations and simulations to guarantee that wind speeds at all working faces remain above 0.25 m/s. This ensures effective dilution and removal of harmful gases, dust, and other pollutants, while keeping dust concentrations below the stringent threshold of 2 mg/m³ to safeguard the respiratory health of workers. Additionally, the drainage system is designed based on the intensity of a once-in-20-year heavy rainfall event, equipped with high-capacity drainage equipment and an extensive network of pipes. This robust setup ensures that even during extreme weather conditions like intense downpours, accumulated water can be promptly removed, preserving a safe and stable working environment underground.

Techno-economic Optimization Principles

Techno-economic optimization is the key to maximizing economic benefits while meeting the mine's annual production capacity requirements. By conducting a detailed techno-economic analysis of various development schemes, the option with the smallest capital construction volume and shortest investment payback period should be prioritized. For instance, in the development of a shallowly buried ore deposit, adopting a decline-based development approach—compared to shaft mining—eliminates the need for deep excavation and complex shaft construction, reducing capital investment by approximately 30%. Additionally, the construction timeline is significantly shortened, enabling the investment payback period to be 2 to 3 years shorter than that of the shaft-based scheme. Meanwhile, given the uncertainties surrounding the mine's future growth, it’s crucial to design the development plan with a 30%–50% capacity expansion margin built-in. This can be achieved through a modular design philosophy, ensuring that critical infrastructure such as roadways, hoisting systems, and ventilation systems are easily adaptable for future capacity upgrades, thereby minimizing both the difficulty and cost of expanding operations down the line.

From the perspective of life-cycle costs, we comprehensively consider the expenses associated with development plans across all stages—including tunneling, hoisting, ventilation, and maintenance. Taking hoisting as an example, shaft hoisting offers fast speeds and high lifting capacity, typically resulting in a cost of 8 to 12 yuan per ton of ore. In contrast, inclined shafts, while slower in hoisting speed and experiencing greater wire-rope wear—and thus higher maintenance costs—often incur a hoisting cost of 10 to 15 yuan per ton of ore. When the orebody is relatively shallow, inclined shaft development may actually lead to lower overall costs. However, as the depth of the orebody increases, the advantages of shaft hoisting—in terms of both efficiency and cost-effectiveness—become increasingly evident. Therefore, it’s essential to conduct a thorough cost-benefit analysis, taking into account specific factors such as the depth and geological conditions of the orebody, in order to select the option that minimizes annual operating costs and ensures the long-term, stable economic operation of the mine.

Principle of Resource Efficiency

Efficient resource utilization is one of the core objectives for achieving sustainable development in mining. In mine planning and design, precise geological modeling and optimized roadway layouts ensure that the area occupied by safety pillars does not exceed 5% of the total orebody area, thereby minimizing ore losses caused by pillar retention. Additionally, the strategic placement of shafts—positioned as close as possible to the center of the orebody—helps reduce ore transportation distances while simultaneously cutting down on resource waste stemming from surrounding pillar areas around the shafts. Combined with advanced mining techniques such as backfilling methods, timely filling of mined-out areas not only effectively controls ground pressure and ensures safe operations but also further lowers ore loss rates, keeping them below 8%.

In terms of industrial site planning, we strictly adhere to the Land and Resources Ministry's standards for mine construction land use, thoughtfully arranging various facilities to enhance land-use efficiency. The green coverage rate of the industrial site will be no less than 20%, minimizing its impact on the surrounding ecological environment. Additionally, we are building complementary facilities for tailings resource utilization, enabling the recovery and reuse of valuable components from tailings, thereby reducing the environmental pressure caused by tailings discharge. Meanwhile, during the mining process, we employ sophisticated extraction techniques and rigorous quality control measures to keep the ore dilution rate below 10%, ensuring high-quality mined ore while achieving the dual objectives of efficient resource development and sustainable land use.

Key factors influencing the selection of expansion strategies

Geological occurrence conditions

Surface topography determines the type of mining development: mountainous terrain (with elevation differences exceeding 50 meters) typically favors the adit-sluice system, while plains areas are better suited for shaft-driven mining methods. The dip angle of the orebody is a critical factor—steeply inclined orebodies (>45°) or gently inclined ones (<15°) see vertical shafts offering 30% higher hoisting efficiency compared to inclined shafts. For moderately inclined orebodies (15°–45°), inclined shafts generally result in 15%–20% lower overall costs than vertical shafts. In terms of mining depth, when depths exceed 500 meters, vertical shafts clearly outperform inclined ramps due to their superior ability to handle pressure challenges; meanwhile, inclined ramps become less viable as ventilation costs soar dramatically. Ultimately, the optimal approach should be determined through a thorough techno-economic comparison.

Engineering and Technical Specifications

The stability of the rock mass determines the roadway support method. For rock masses with poor stability (Poisson's ratio f < 6), reinforced concrete support is required, increasing costs by approximately 40% compared to conventional anchor-spray support. In such cases, the overall stability of a vertical shaft is superior to that of an inclined shaft. From a hydrogeological perspective, in mining areas where water inflow exceeds 100 m³/h, the vertical shaft drainage system must be equipped with multi-stage centrifugal pumps. Meanwhile, maintaining drainage pipelines in inclined shafts is particularly challenging, making vertical shafts the preferred option. In terms of mechanization levels, large-scale mines (>3 million tons/year) are best suited for vertical-shaft skip hoisting or belt-conveyor inclined shafts, while smaller and medium-sized mines (<1 million tons/year) can achieve greater cost-effectiveness by using cage-type vertical shafts or vehicle-access inclined ramps. Equipment selection should always align closely with production capacity requirements.

External Construction Conditions

Industrial site selection must meet flood protection standards (return period ≥ 50 years), avoid areas prone to landslides and debris flows, and be located at least 500 meters away from residential areas. External transportation conditions significantly impact ore-handling costs: rail transport is ideal for large-scale mines handling more than 5 million tons annually, while road transport is better suited for smaller-to-medium-sized mines—provided that the slope of access roads remains below 8%. From a policy perspective, the site must comply with the "Safety Regulations for Metal and Non-Metallic Mines" (GB16423-2020), fully implement ecological protection redline requirements, and ensure that the mining development plan has successfully passed both the safety facility design review and the environmental impact assessment. By systematically comparing the technical and economic indicators of major development tunnels, combined with the mine’s specific site conditions, stakeholders can adhere to principles of safety, cost-effectiveness, and operational efficiency. Careful consideration of critical factors such as geology, technology, and the external environment will enable the scientific formulation of an optimal development plan, laying a solid foundation for safe and efficient operations throughout the mine’s entire lifecycle.